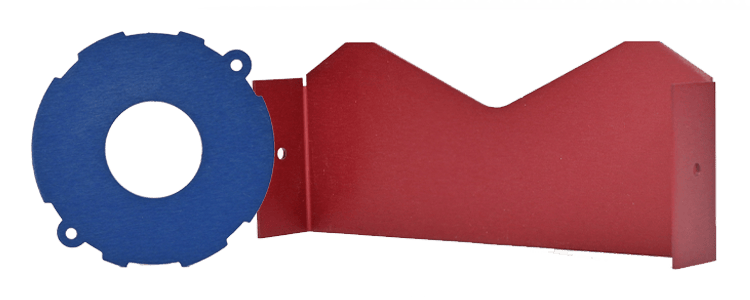

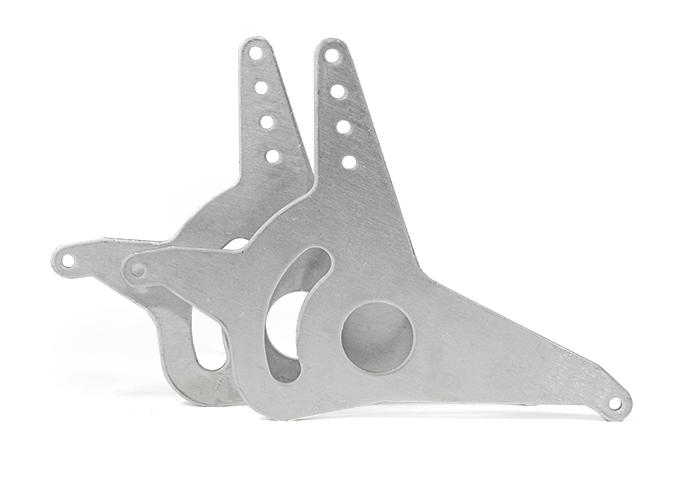

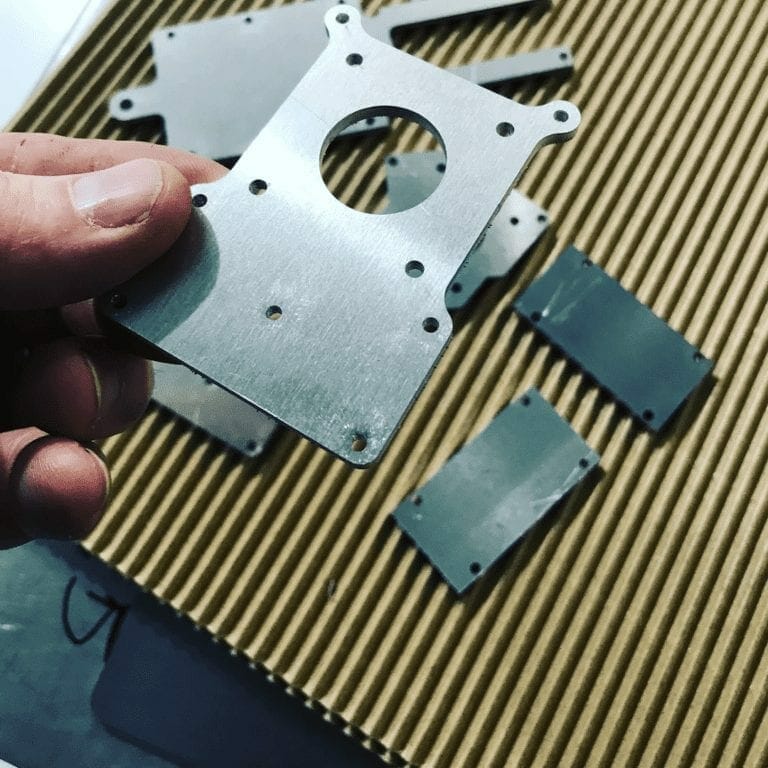

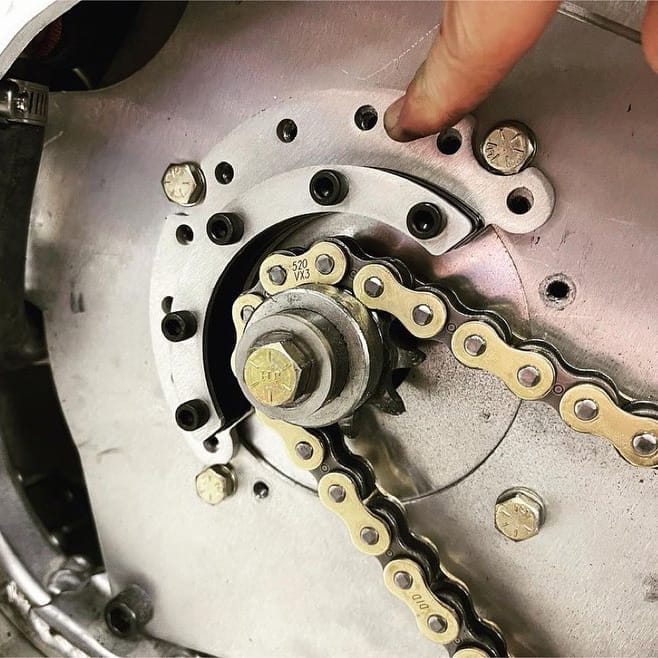

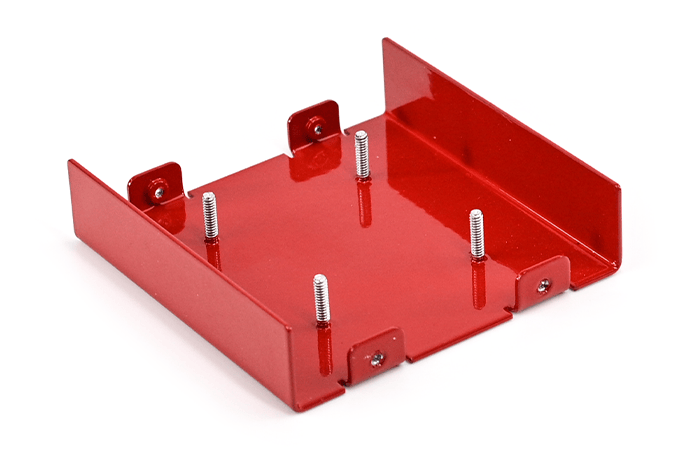

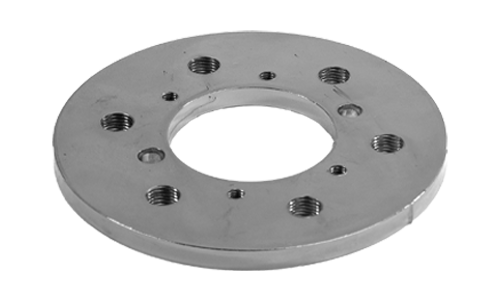

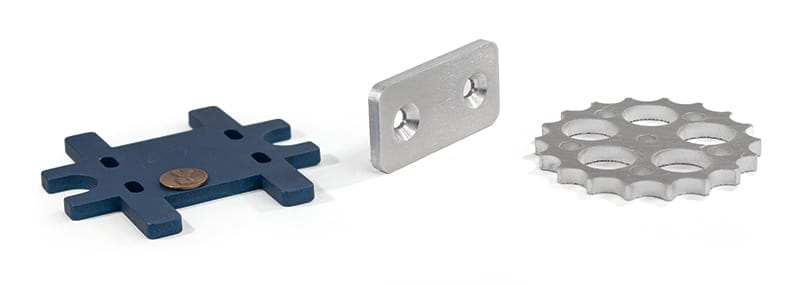

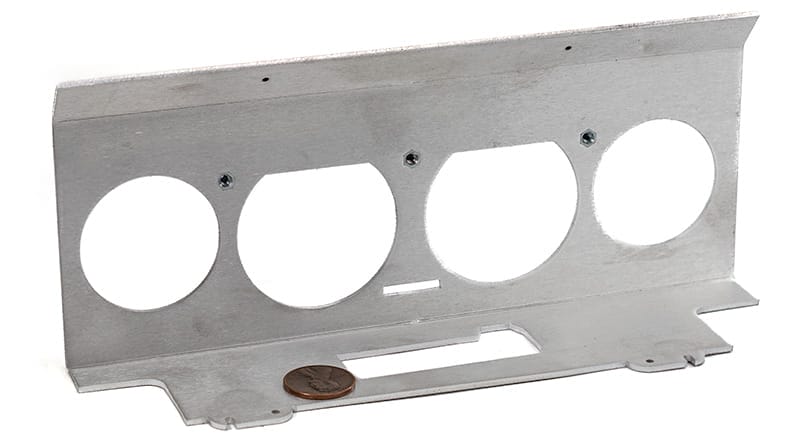

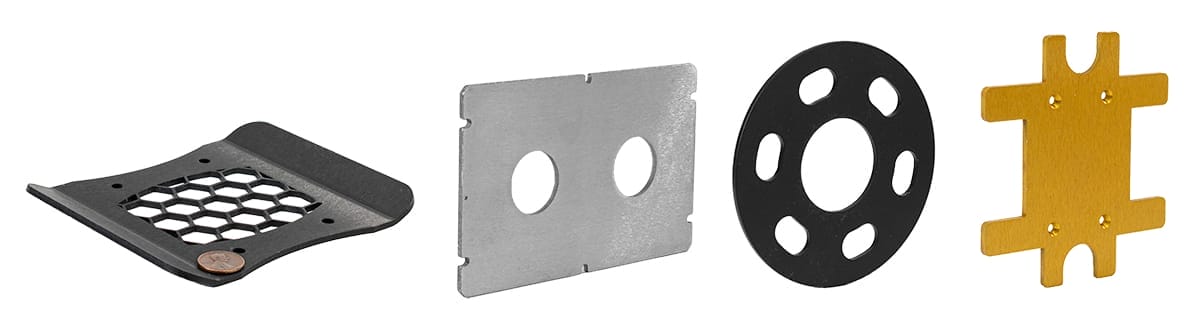

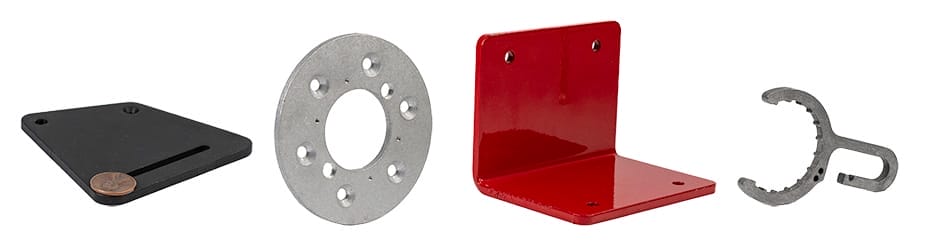

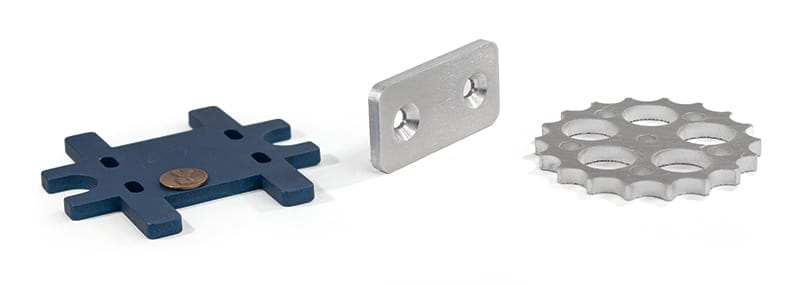

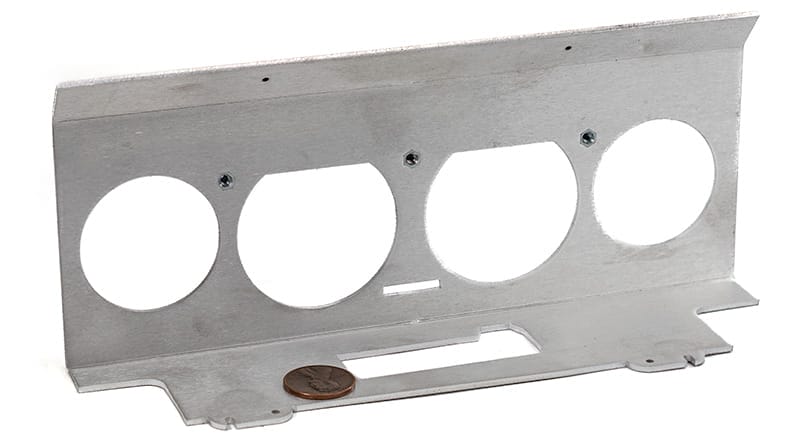

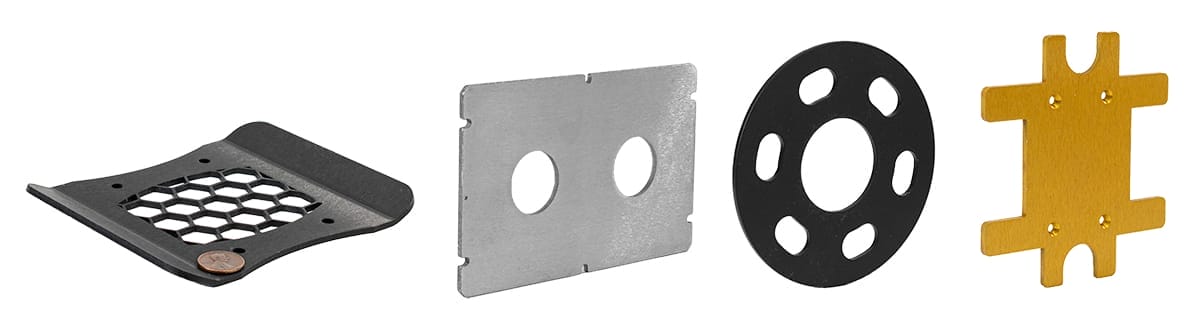

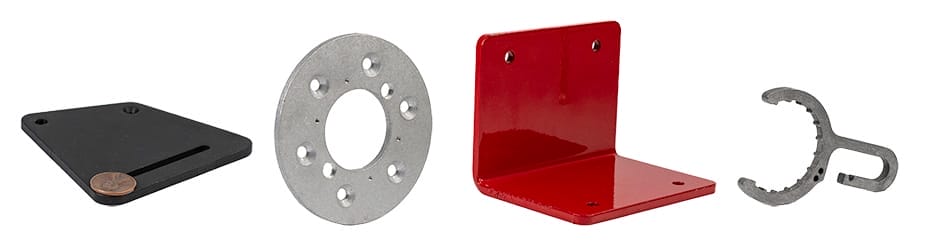

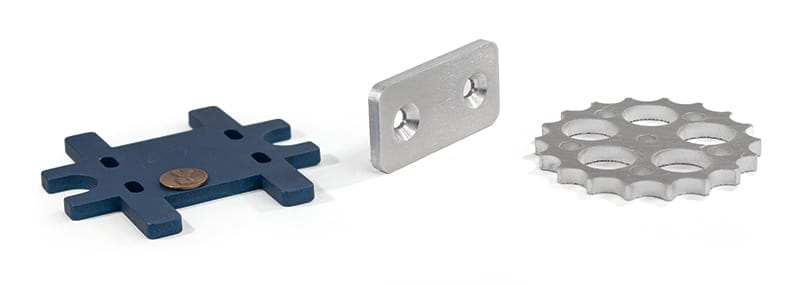

Laser cut 5052 aluminum is one of our most popular metals. Used in a wide variety of applications including aerospace, automotive, and robotics, our 5052 H32 aluminum is an excellent mix of high performance and affordability.

5052 H32 aluminum is strong, inexpensive, and lightweight. Whether you’re welding, machining, or bending, 5052 aluminum is going to be the go-to material for those projects that need excellent all-around material properties. Our laser cut 5052 aluminum is exceptionally lightweight and strong, making it perfect for projects where overall load is a concern.

With high relative ultimate strength (and fatigue strength), 5052 aluminum has a number of practical usages. It is non-heat treatable, which means that it is cold-worked to achieve its moderate-to-high strength properties. For greater strength, check out our 6061 series aluminum.

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

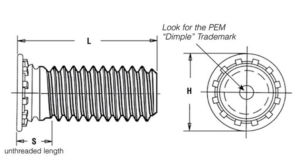

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |