Thinking of cleaning up the edges of your laser cut aluminum, copper, brass, stainless steel, or titanium? Linear deburring and ceramic tumbling are great ways to tidy up the finish and remove burrs from a wide variety of metal parts. Luckily SendCutSend offers both, completely free of charge.

Sheet Metal Deburring

Sheet metal deburring is the process of removing dross, burr, minor scratches, and imperfections that were created in the manufacturing process. No matter what initial machining process you use, be it laser cutting, waterjet cutting or CNC routing, there will often be burrs or scratches left over from the manufacturing process. It’s easy to remove the imperfections and leave you with a clean, smooth-to-the-touch part (although it may not be cosmetically perfect).

Burrs and minor scratches can be removed using a variety of processes, both manual and mechanical. Different deburring processes are ideal for different machining processes, and you can trust us here at SendCutSend to do right by your parts depending on what material they are.

Sheet metal deburring is important for safety, and it provides a great starting point for downstream operations such as painting, polishing, or anodizing. Deburred parts are easier to assemble and create less wear-and-tear on your hands, and if you are looking to paint or powder coat your parts, deburring is a necessary process. If you plan on sandblasting or bead blasting your parts, deburring may not be necessary.

If you want us to deburr your laser cut parts, make sure they are a minimum of 3 inches on the longest axis, and a maximum of 24 inches on the shortest axis. Keep in mind that while deburring is great for cleaning up obvious imperfections and burrs on the edges of your parts, it is not a cosmetic finishing operation, so there may still be scratches or sharp edges on your parts.

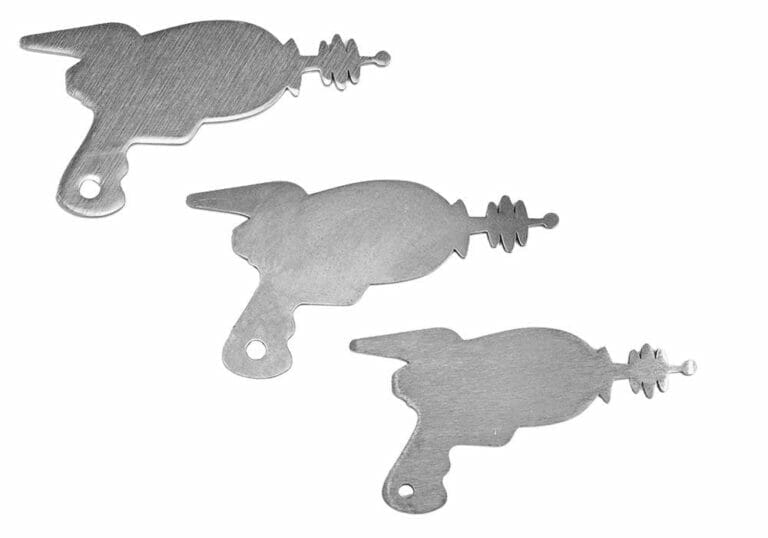

Ceramic Tumbling and Edge Softening

Ceramic tumbling is our option for smaller parts that need to be smoothed. See our processing minimum and maximum flat part size chart to confirm if your parts are eligible for the service.

Because of the size of the parts and the nature of ceramic tumbling, we cannot guarantee a uniform finish. However, just like deburring, it gives a great finish for later polishing or chemical brightening. Ceramic tumbling also gives some materials, such as brass and copper, a partially “antiqued” look with a soft edge.

SendCutSend’s technology is a little different than the home rock tumblers that you might be familiar with. We use specialized equipment that is harmonically tuned to the specific material we are tumbling. It’s more of a vibratory-abrasive process than “tumbling”, but tumbling is a more common term. The harmonically-tuned vibratory abrasive process allows us to have a more consistent finish and shorter cycle times than an at-home process.

If you select “deburring” when placing your sheet metal order, we may use our discretion and tumble your parts instead of debur them due to their size. Our awesome support team will keep you in the loop about where your parts are at in the manufacturing process and will let you know how they are being finished.

Sheet Metal Deburring Myth

The biggest sheet metal deburring myth is that it will give your part a “finished” appearance. Deburring does not make your part look perfect; it just removes the sharp edges and machining imperfections. The finish it gives the part does make it attractive and clean, but it’s far from cosmetically perfect. If you are needing a polished shine or aggressive edge-softening, we recommend chemical washing/brightening or performing finishing operations yourself in order to give the sheet metal the finished sheen you’re looking for.

Deburring Sheet Metal with SendCutSend

We take pride in the quality of our machining and deburring processes, and we quality control your parts every step of the way to be sure they live up to the high standards we have set for ourselves. While we can’t guarantee a perfect finish, our deburring process will give you a great smooth surface for powder coating, painting, or putting your own final touches on your parts.

Got more questions about deburring sheet metal? Reach out to our support team anytime.

Or if you’re ready to go, upload your design and get an instant quote for deburred sheet metal parts today!