Foothill Products went from using SendCutSend for personal projects to full production runs for custom cycling gear. Today, they order several hundred parts at a time for their business, utilizing SendCutSend’s fast and simple laser cutting services. Keep reading for inspiration on how your business can leverage SendCutSend services to grow in its success.

Introducing Foothill Products

Douglas Schaller is a long-time industrial designer, bringing sleek, functional products to every market-space he occupies. His attention to detail lends itself to the clean, classic lines that many of his designs feature. Schaller has accumulated 15 years of experience in the industrial design space, as both a freelance consultant and full-time designer.

Outside of industrial design, Schaller is also a successful amateur cyclist, a hobby he and his wife share. Seeking to organize his own space and equipment, Schaller designed a few hooks to hang his bike wheels. These early designs were the beginning of Schaller’s successful cycling accessory business, Foothill Products.

“Initially I designed these hooks to hang all the bike wheels my wife and I have, but soon after I created them, I thought, ‘We could probably sell something like this!’ It went from being a side project to what I do full time now.”

The Offset Hook is the original product Schaller designed, and you can still purchase it today from Foothill Products. The Foothill Products line has since grown to include other organizational hooks, stationary bike accessories, and cycling computer mounts.

Foothill Products and SendCutSend

Since Foothill Products initially began as a side project, Schaller was doing limited production runs from several other companies and doing basic early prototyping by himself. Demand for his products quickly grew, however. Cycling has always been one of the world’s favorite pastimes, and exploded even more in recent years as people sought outdoor activities.

“Even though cycling is one of the most popular outdoor activities in the world, my production runs are smaller than a lot of other markets because I make accessories specifically for the ‘cycling aficionado.’ But because my products fit the cycling niche so well, the demand for my products got too big for my early production methods.”

With the company growing quickly, Schaller reached a point where he needed quick and simple manufacturing for his products to make them affordable and accessible to his customers. Additionally, he sought high quality manufacturing to ensure that what he produced lived up to the standards he set for his company early on. Schaller put a few of his designs into our instant quote tool, and finding that full production runs from SendCutSend were more than viable for his business, moved to using our process for several of his current products.

Initially utilizing SendCutSend for small scale prototyping, Schaller found our processes easy to use with a fast turnaround time. This was helpful for his rapid prototyping, but became increasingly valuable as he turned to us for larger scale production.

“I started using SendCutSend for prototyping, which worked well, but I love that I can do a prototype order and then just reorder the exact same parts in a higher quantity for my full production runs. It’s made it really easy to order upwards of 300 parts at a time.”

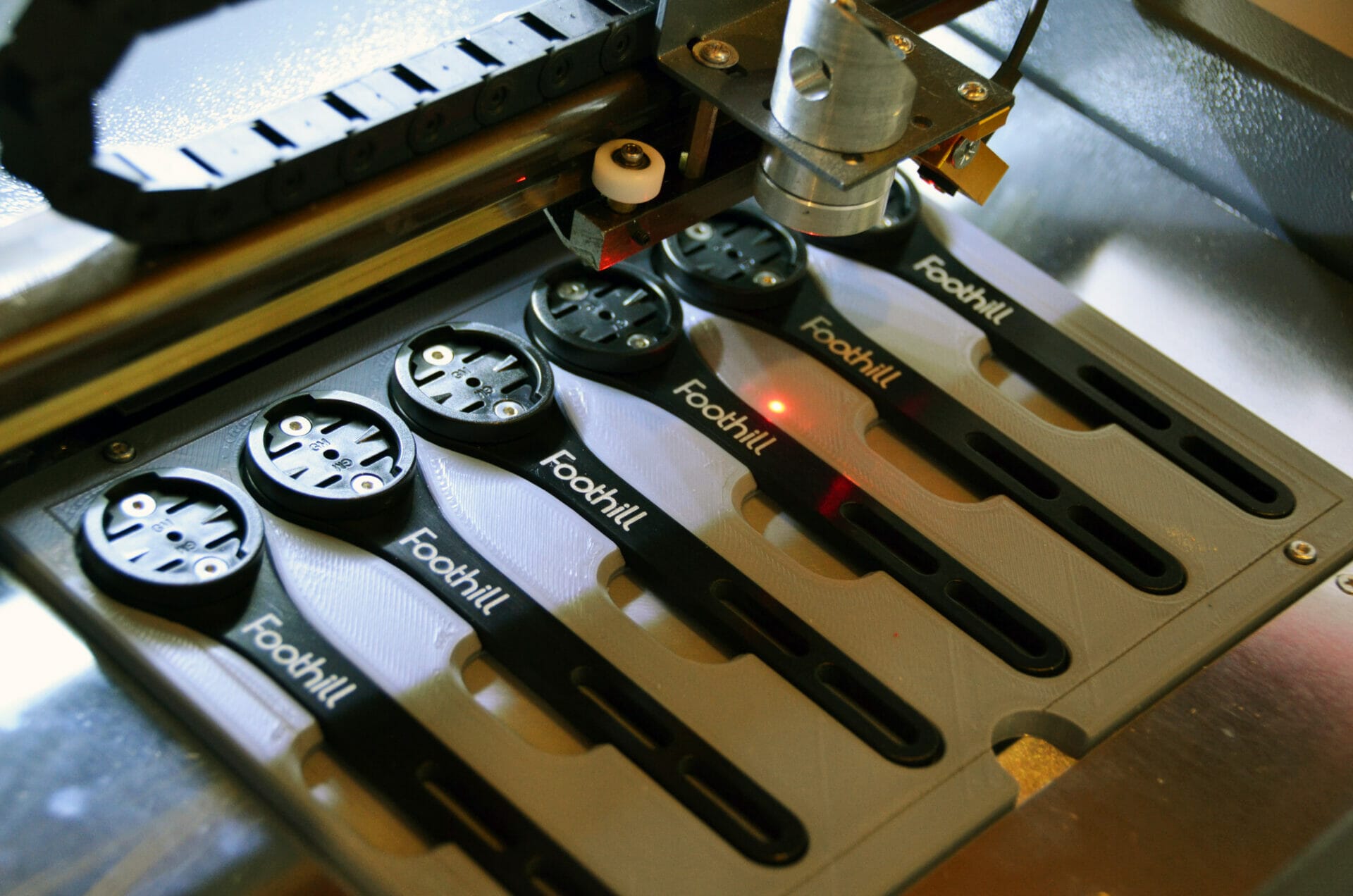

SendCutSend currently laser cuts three of Schaller’s products: the Out Front Mount, the Offset Vert, and the Bottle Lever. These are essential products for the “cycling aficionado,” as Schaller refers to many of his customers. After receiving the initial products from SendCutSend, Schaller has them anodized (anodizing services have been added to SendCutSend’s offerings since this was written) and then beautifully laser etches the Foothill Products logo into the parts. Featuring state of the art manufacturing and processing at every stage, we are proud to be a part of Schaller’s success story.

“Using SendCutSend’s deburring process was as much of a game changer as using the laser cutting service. Before I started using it, I was deburring thousands of parts by hand and it was just taking too much time. Now my parts come to me ready for etching and it’s really nice.”

Schaller’s Advice for Business Owners

As someone who has gone from using SendCutSend on a personal scale to doing full production runs with our laser cutting and deburring process, Schaller has some advice for business owners looking to use SendCutSend for their next projects:

- Make sure you have a clean CAD file.

“I use SolidWorks for all my designs because that’s what I’ve always used. But if you’re designing in SolidWorks to export to a flat file, especially for SendCutSend, double check your file for connected and non-intersecting lines. You’ll have a much nicer file to upload.”

- Use SendCutSend for rapid prototyping.

“What I first loved about SendCutSend was that I could basically order prototypes on demand and the parts would be there in a couple days. It made prototyping a lot more cost effective, which makes it easier to make my products better. And it’s such an easy switch to full production runs because your file is already there.”

- Use the instant quote tool to check your costs.

“I upload parts to the instant quote tool all the time just to make sure I can design the part cost effectively to be cut by SendCutSend. It’s easy to just make fast adjustments and then upload the part again, and I don’t have to wait on a quote.”

- Parts from SendCutSend are Made in the USA.

“Being able to say that my products are made in the USA makes a big difference in marketing, especially overseas. It’s the same as getting an Italian-made bike here: there’s an expectation about the quality that you know will be met.”

If you have questions about utilizing SendCutSend for prototyping and full production runs for your business, don’t hesitate to reach out to us!

Setting Up Your Business for Success with SendCutSend

We can’t wait to see what Foothill Products does next and are looking forward to being part of it. If you want to follow along with Schaller and his business, be sure to follow them on Instagram at @foothillproducts. And check out their amazing products and cycling apparel, whether you’re a cyclist or just looking for inspiration for your next SendCutSend venture.

It doesn’t take much to set up your business for success with SendCutSend: just upload your product design and get a quote instantly for most of our services. Have further questions or need a custom quote? Just reach out to our support team and they’ll get you set up in no time.

Do you already use SendCutSend for your business and other projects? We’re looking for people like you to show off what your designs are capable of when paired with our manufacturing processes. Use our Partner With Us form to tell us about it and we’ll be in touch!