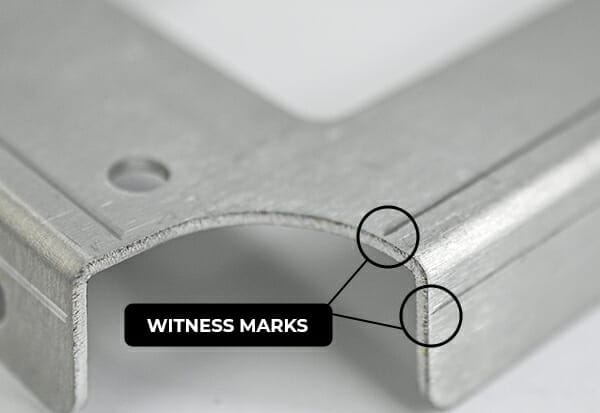

The tooling used in press brakes will often leave a surface mark on the bent sheet metal. These marks are called die marks, die lines, or witness marks, and while difficult to prevent, there are a few things you can do to hide or eliminate the unwanted markings.

SendCutSend does not offer die protection or mark removal, but one of the things you can do to minimize the effect the tooling has on your part is choose a harder material, such as stainless steel. The die marks on stainless steel won’t be as deep as on softer materials, and can be more easily removed or hidden. To blend out the die marks on your part, a dual action (DA) orbital sander works best.

Be sure to read our bending guidelines before you get started designing your part for our online bending service.

In Summary

The tooling used in press brakes will often leave a surface mark on the bent sheet metal. These marks are called die marks, die lines, or witness marks, and while difficult to prevent, there are a few things you can do to hide or eliminate the unwanted markings.