Every year, SendCutSend heads to Las Vegas, Nevada to participate in the SEMA Show. SEMA is a premier automotive trade show where manufacturers and enthusiasts alike show off their most recent products and capabilities.

Being a mere 8-hour drive away from SendCutSend’s Reno facility, we wanted to roll into SEMA in a big way. It was also the perfect opportunity to build a project that was 100% constructed of SendCutSend’s materials, processes, and services.

Enter “Jet-A-Send”

Jet-A-Send was masterminded by SendCutSend’s R&D team to demonstrate our on-demand manufacturing services and technology.

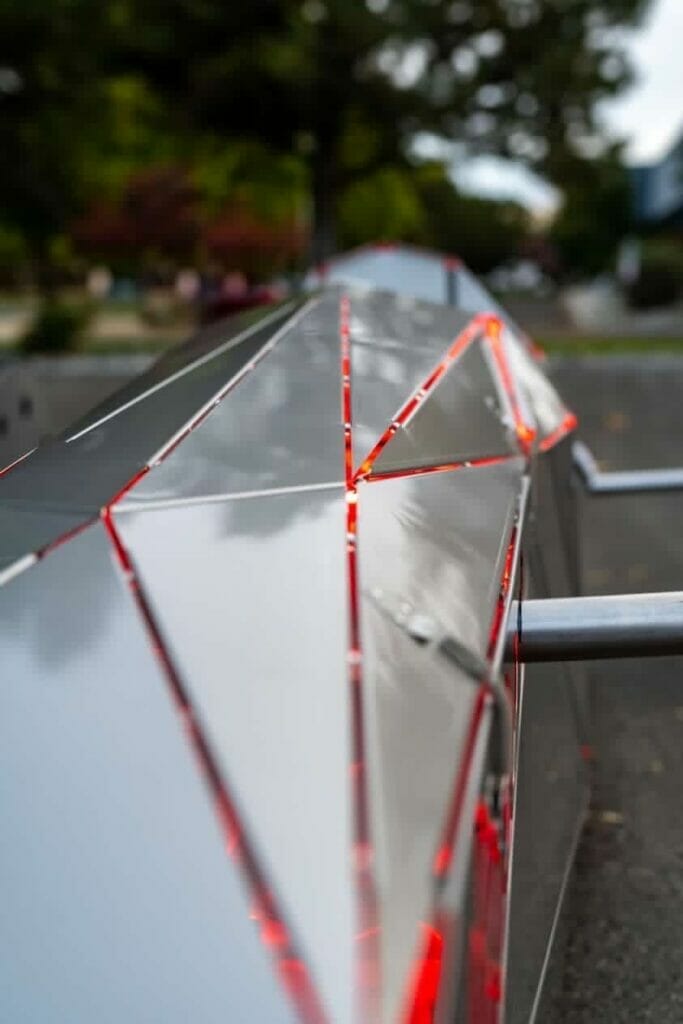

The turbine-electric powered streamliner features a laser-cut stainless steel body and aluminum chassis which uses high-precision CNC bending, tapping, and countersinking.

The vehicle is finished with clear, red, and black anodizing; yellow and black zinc plating, and various raw materials including carbon fiber.

Jet-A-Send’s Mini Jet Engine

A 10hp JetCat Turboshaft provides electrical power to onboard lithium batteries, which in turn power the three-phase, 25 kW AC motor by Electro & Company. The turbine-electric motor gets 300 miles per gallon (Jet A, Kerosene, or Bacardi 151). Jet-A-Send weighs in at roughly 388 pounds without a driver.

Once we were on our way to Vegas, we had to test the Jet-A-Send on the road. The only issue is that it was designed to run on the incredibly smooth surfaces of the salt flats and not the unknown roads of Tonapah, Nevada. We charged on and upon firing up the Jet-A-Send we quicky learned that you could feel every part of the car as a result of it’s lack of suspension and seat padding. You’re literally sitting on precision laser cut sheet metal. At low speeds the Jet-A-Send is eerily quiet from the electric power plant but once the turbine kicks in to charge the batteries the sound is deafening.

All this suffice to say that it was significantly faster than we expected, which also led to some issues when breaking. All in all, driving the Jet-A-Send was like driving in a tin can that’s vibrating with no sound deadening and coupled with some “oh shit we built this ourselves” adrenaline. This version was a prototype built for a trade show, but we’re excited for the second version which will be a little more street friendly.

How to Get Started with Custom Laser Cutting

The Jet-A-Send took 190 hours to design and 28 hours to assemble. Whether you’re looking to build a custom vehicle or rapid manufacturing of some custom parts, SendCutSend offers custom laser cutting services, fast.

You can get started with SendCutSend by uploading your design to our app to get an instant quote. With more than 165 materials and 15 post-processing services to choose from, we can cut just about anything you can dream up.

Be sure to check out our guidelines before uploading your project.