Please keep in mind that this list is not all-inclusive, but it should help point you in the right direction. Our team of Application Engineers is always available to help answer questions too, reach out anytime.

| Material | Recommended | Comments |

|---|---|---|

| Aluminum (5052) | Yes | Aluminum will do well outside but will turn a dull grey and oxidize over time |

| Brass | Not recommended outdoors unless coated or polished. Will patina and tarnish easily. | |

| Copper | Copper is great for decorative outdoor use if you prefer a green patina | |

| HDPE | Yes |

HDPE is great for impact resistance and low moisture absorption. It’s a great alternative to wood in harsh outdoor environments. |

| Mild Steel | Mild steel will rust quickly if left uncoated. | |

| Stainless Steel (316) | Yes | Our preferred material for outdoor applications when no coating will be applied |

| Carbon Fiber | Not recommended for long-term outdoor use since UV rays can damage the epoxy part of the composite | |

| ACM | Excellent for outdoor usage. | |

| Titanium | Very stable, will not corrode or patina. Will oxidize slightly. |

| Material | Recommended | Comments |

|---|---|---|

| Aluminum | Yes | Aluminum is relatively soft and flexible, and will turn a dull grey if left uncoated. |

| Brass | Yes | Brass is great for decorative use. We recommend adding a clear coat or polish to prevent patina. |

| Birch | Yes | Birch is perfect for cabinetry, art, and craftwork. |

| Copper | Yes | Copper is great for decorative use. We recommend adding a clear coat or polish to prevent patina. |

| Brass | Yes | Brass is great for decorative use. We recommend adding a clear coat or polish to prevent patina. |

| Mild Steel | Mild steel will rust quickly if left uncoated. | |

| Stainless Steel | Yes | Our preferred material for signage and decorative items that will not be painted or coated. |

| Carbon Fiber | Cost-prohibitive for decorative uses. | |

| ACM | Yes | Excellent for signage. |

| Titanium | Cost-prohibitive for decorative uses. |

| Material | Recommended | Comments |

|---|---|---|

| ABS | This plastic has great impact and abrasion resistance, high tensile strength and heat and chemical resistance. | |

| Aluminum (6061, 7075) | Yes | 6061 and 7075 series Aluminum is much stronger and stiffer than our standard 5052 series. 7075 Aluminum is comparable to titanium for strength. |

| Brass | Brass is great for decorative use, but is very soft and ductile. Not recommended for any application subject to load or bending forces. | |

| Copper | Copper is great for decorative use, but is very soft and ductile. Not recommended for any application subject to load or bending forces. | |

| Delrin® 150 | Yes | High strength, great abrasion resistance, yet is still machinable. |

| Mild Steel (4130, AR500) | Yes | Our 4130 series and AR500 steel are very high strength and offer significant advantages over standard mild steel (A36). |

| Stainless Steel | Yes | Significantly stronger than mild steel, with increased weight. Will not corrode or rust. |

| Carbon Fiber | Yes | Our highest strength-to-weight material. Incredibly strong and rigid. Not recommended for use in temperatures over 140 degrees F. |

| ACM | Not recommended for high-strength or load-bearing applications. | |

| Titanium | Yes | One of our highest strength-to-weight materials. Incredibly strong and rigid. |

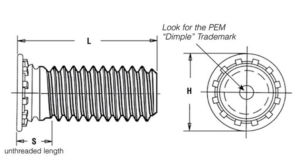

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |