“Ordered Sunday night, came in Tuesday morning. Parts were exactly as I ordered them within the tolerances they specified for the material. The site has tons of great resources for how to set up you CAD model to make parts as accurate as possible and make sure they make the part right. Everything came in a nice sealed package. Even came with candy! The automatic quotes are awesome and give you instant feedback on manufacturability and price. Will definitely be buying more from them in the future.”

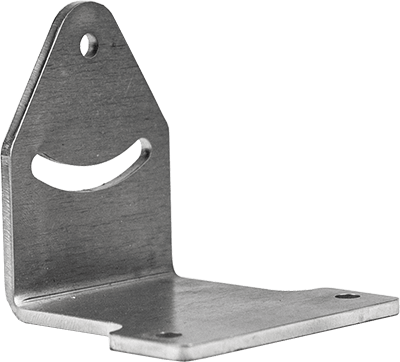

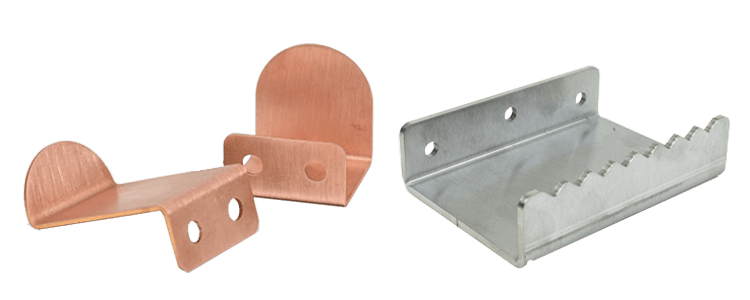

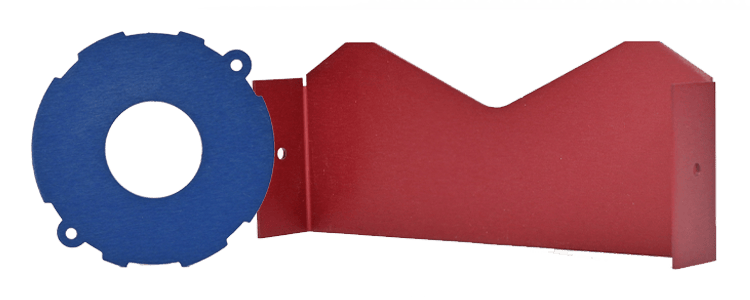

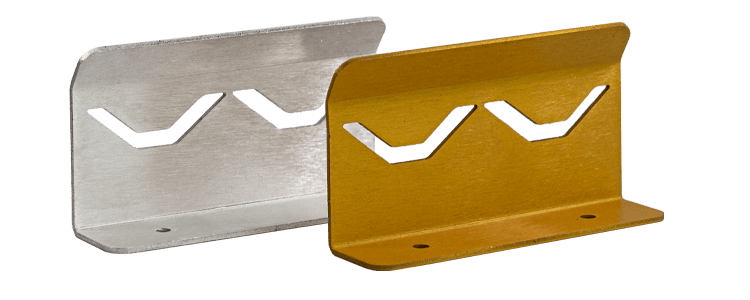

Our CNC routing service delivers clean, accurate cuts whether you need a single part or thousands. CNC routing is ideal for materials like composites, plastics, and wood that don’t respond well to laser cutting. While we use lasers for most metal jobs, routing gives you smoother edges and better finish quality on non-metal parts. Faster cutting speeds also help reduce production time and cost.

We offer CNC routing services for a wide range of materials including plastics, composites, and woods/boards.

For a full list of materials and available thicknesses, please visit our materials page.

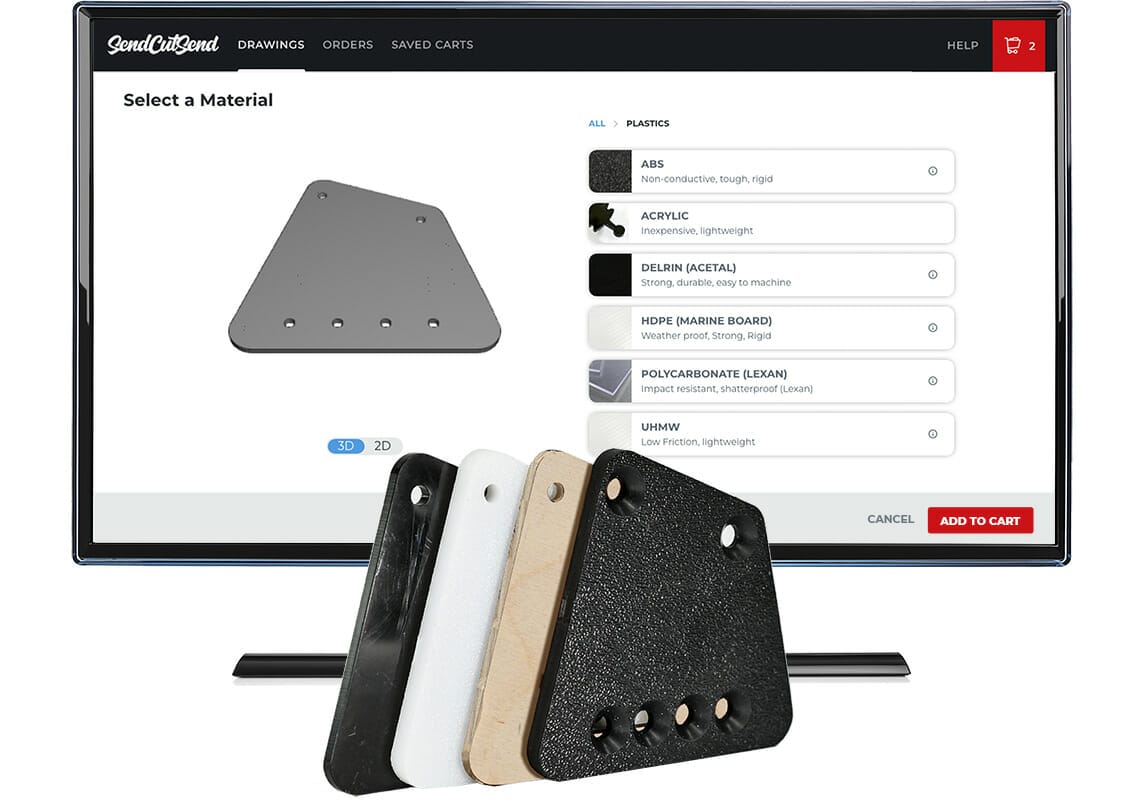

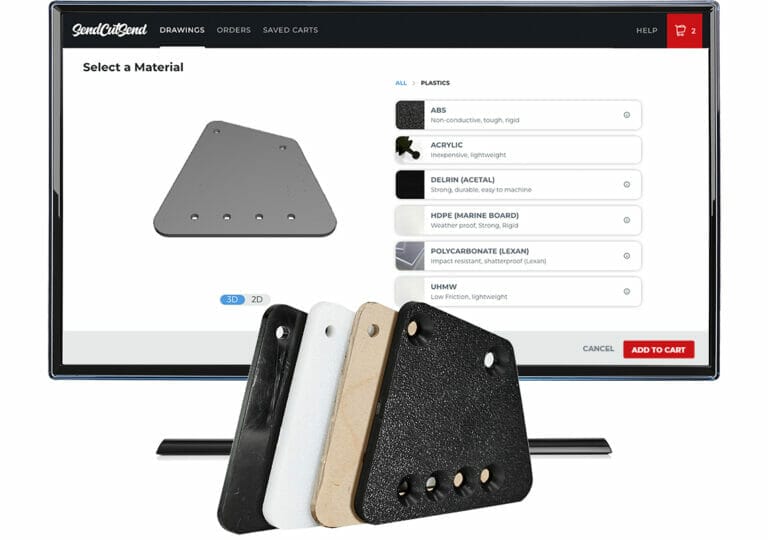

With our team of highly trained machinists and our state-of-the-art manufacturing technology, we’ve made it easier than ever to design and order CNC routed parts. Upload your design to our app, select your material, add any additional services, and get an instant pricing!

Ensure your file meets our requirements to get your parts as quickly as possible.

Ensure your file meets our requirements to get your parts as quickly as possible.

Choose your material and adjust quantity to see live pricing and shipping updates.

We accept, .ai, .dwg, .dxf, .step. or .stp files for CNC routing. We have our Parts Builder or Design Services available if you don’t have a file handy.

Standard production on CNC routed orders is 2-4 days with 1-3 day shipping.

We accept, .ai, .dwg, .dxf, .step. or .stp files for CNC routing. We have our Parts Builder or Design Services available if you don’t have a file handy.

Choose your material and adjust quantity to see live pricing and shipping updates.

Standard production on CNC routed orders is 2-4 days with 1-3 day shipping.

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

Before you upload your design, take a look at our file preparation guidelines. They cover everything you need to know including file setup, sizing, supported formats, and tips for keeping costs down, so you can get the best results from your custom parts.

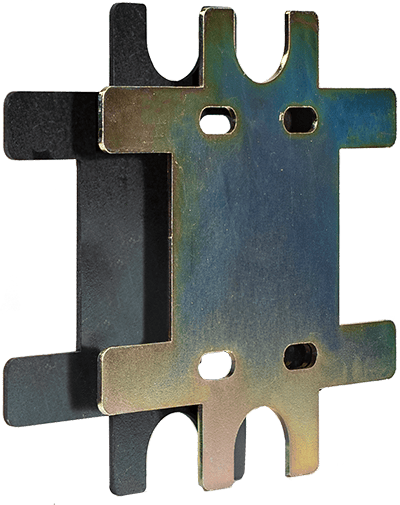

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

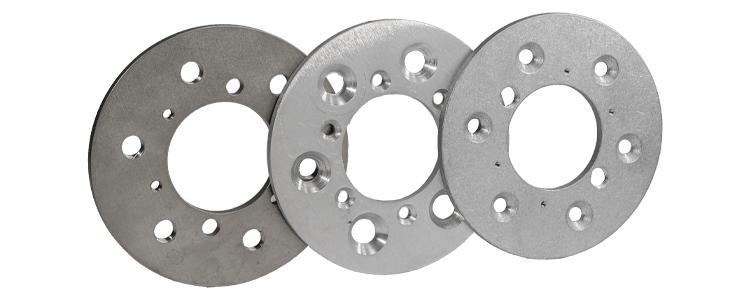

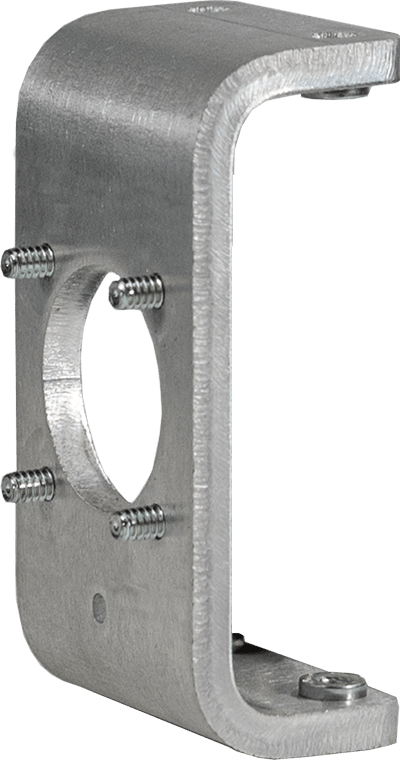

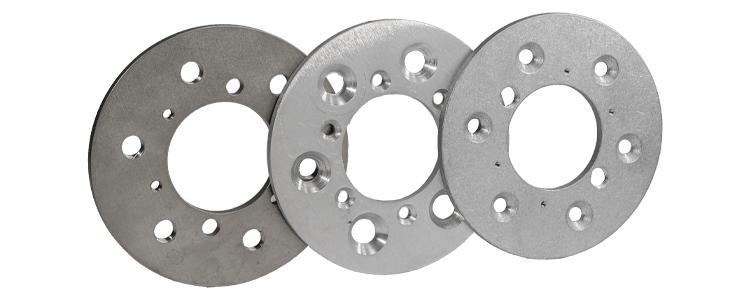

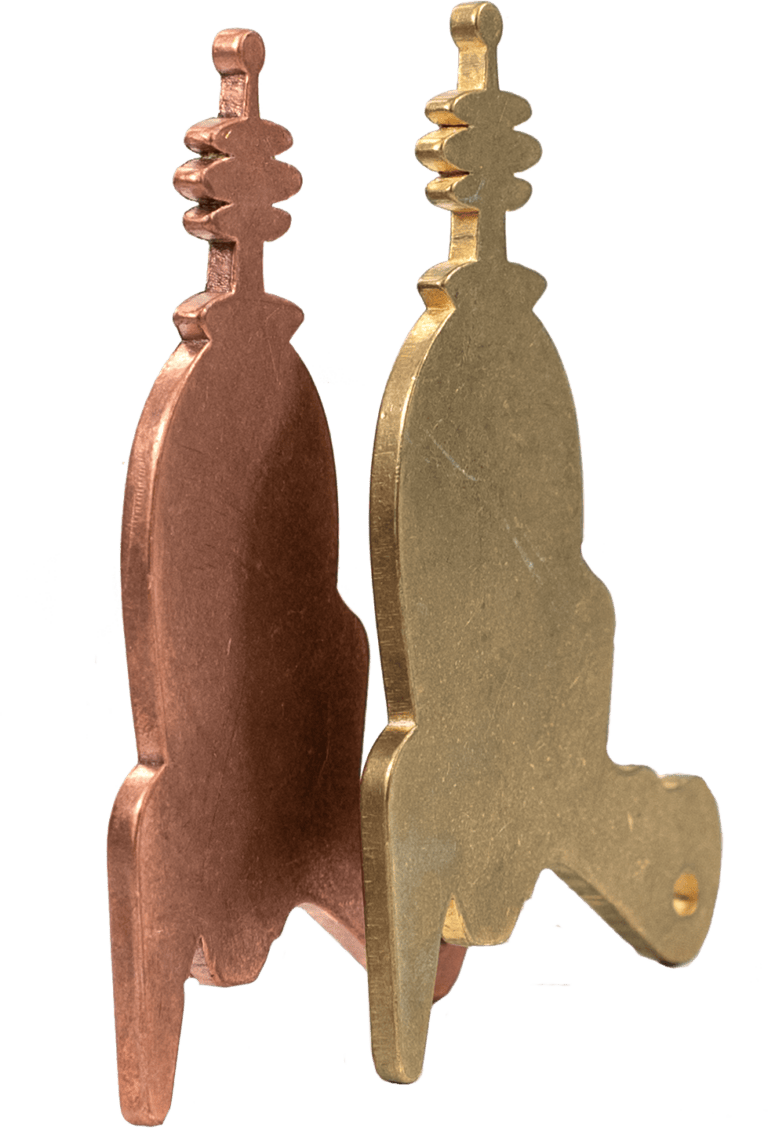

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

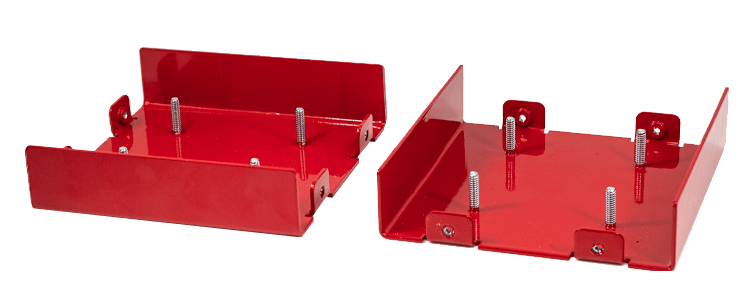

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 12 materials

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 3 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+7-10 days | 9 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

“SendCutSend is a service my business can grow with. It doesn’t matter if I need one component or 10,000. SendCutSend will fulfill that order for me with a rock-solid estimate and time frame up front enabling me to produce a quality product, representative of my craftsman business, which will also generate a profit.”

SendCutSend accepts .step, .stp, .dxf, .dwg, .eps, and .ai (Adobe Illustrator) formats. These formats ensure precise cutting paths and compatibility with CNC routing machines. Some quick tips for preparing your design file for SendCutSend includes making sure all lines are joined, removing duplicate paths, and converting text to outlines. Providing clean, well-structured files helps prevent errors and ensures accurate cuts.

Our CNC routing services offer high accuracy, with cuts achieving tolerances of ±0.005” or better in composites, plastics, and wood products. This level of precision ensures that your parts meet stringent engineering requirements.

SendCutSend will choose to cut your parts on the best machine possible at the most affordable price. Cutting machines are determined based on material, complexity of design, and several other factors. We currently cut a variety of plastics, composites, and woods/boards on CNC routers including ABS, ACM Panel, Baltic Birth Plywood, Delrin, HDPE, MDF, Polycarbonate and UHMW.