I spent over 5 years and thousands of dollars prototyping with different machine shops, prototyping agencies, and contract manufacturers. Before SendCutSend, I usually had to wait a week or two for a quote, a month or more for the pieces to be made, and it cost hundreds to thousands. I got my first order from SendCutSend the same week I ordered! They are the quickest, best quality, and unbelievably most affordable company I’ve had the pleasure to do business with. We were able to crowdfund over $225,000 for our first multi-tool thanks to SendCutSend!

We offer laser cutting services for a wide range of materials including metals, plastics, composites, and woods/boards.

For a full list of materials and available thicknesses, please visit our materials page.

Order 1 or 1,000+. Get up to 80% off when you order in bulk.

Order 1 or 1,000+. Get up to 70% off when you order in bulk.

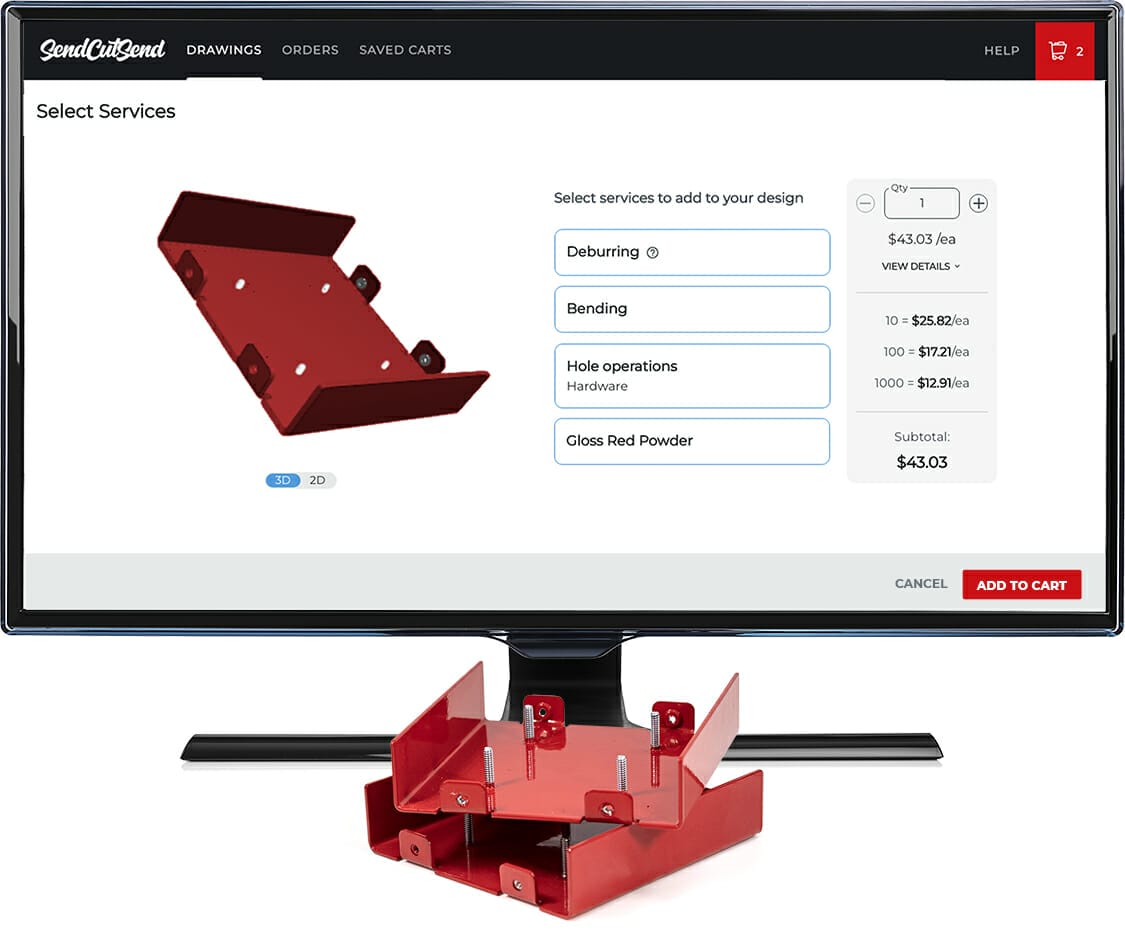

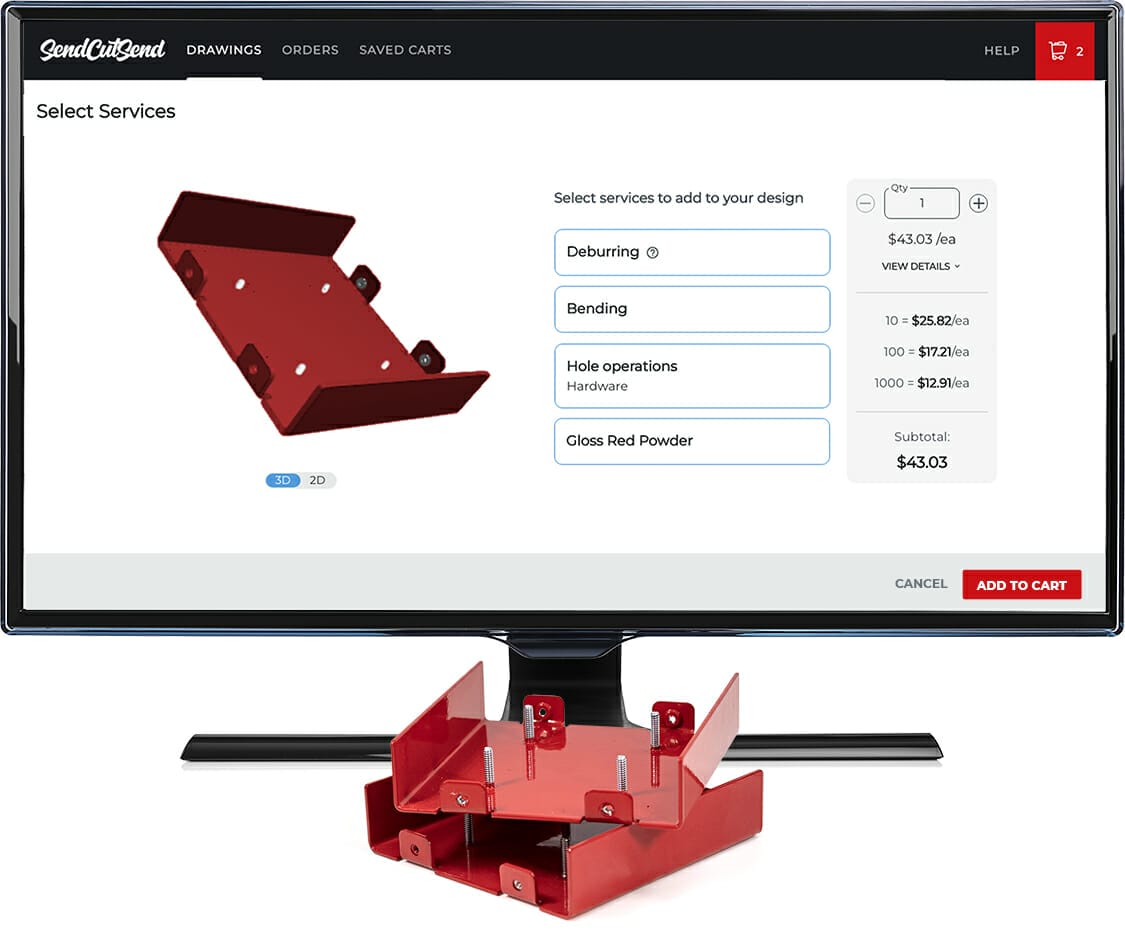

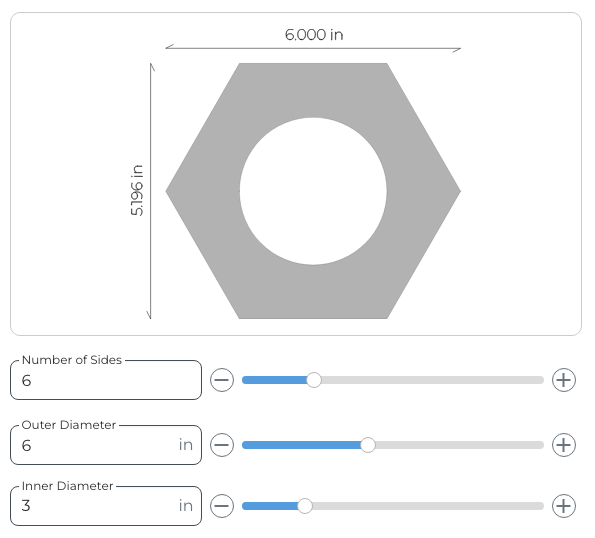

Upload a CAD file, build a part with our Parts Builder, or convert a sketch or template to CAD using our Design Services.

Upload a CAD file or use our parts builder to get instant pricing.

Free shipping in the U.S., and starting from $19 to Canada on orders of $39 or more

Free anywhere in the USA, and only $19 to Canada.

Follow your order from upload to delivery.

Follow your order from upload to delivery.

Before you upload your design, take a look at our file preparation guidelines. They cover everything you need to know including file setup, sizing, supported formats, and tips for keeping costs down, so you can get the best results from your laser cut parts.

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

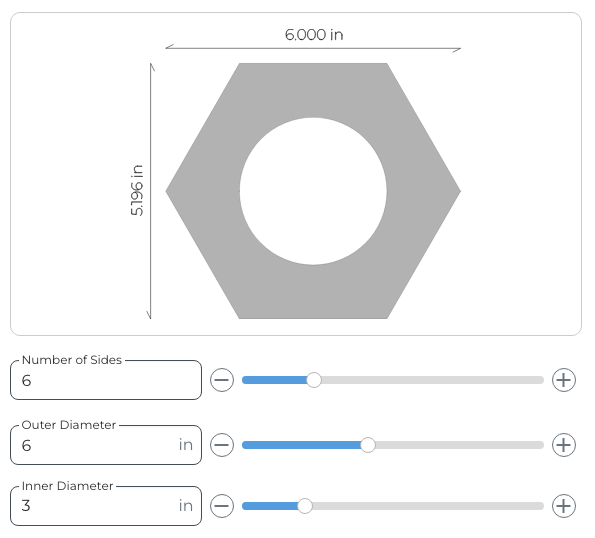

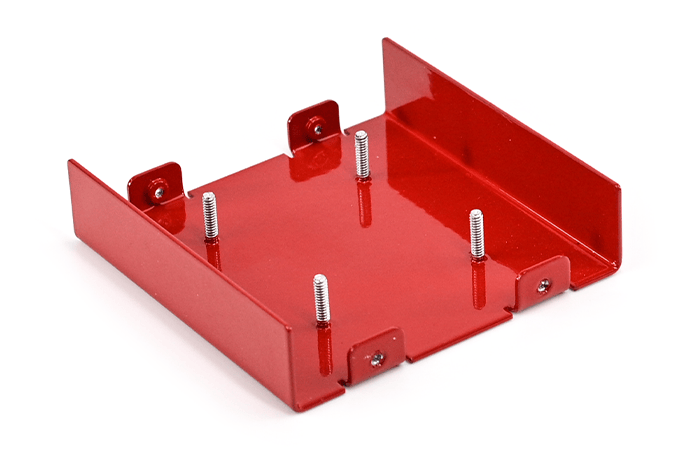

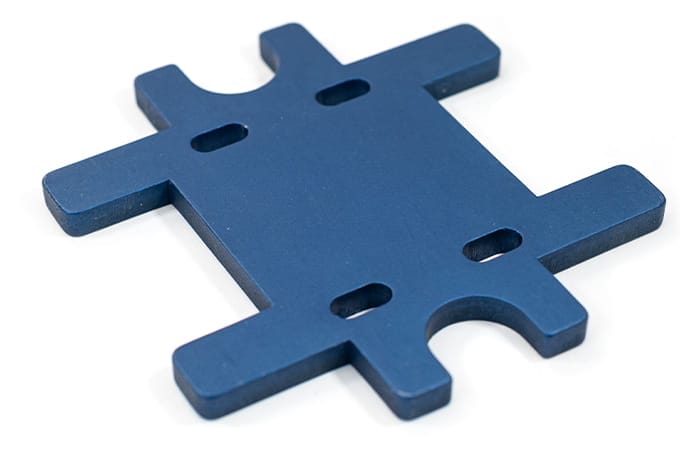

Enhance your laser-cut parts with our range of finishing services

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

Top Quality Store

SendCutSend accepts .step, .stp, .dxf, .dwg, .eps, and .ai (Adobe Illustrator) formats. These formats ensure precise cutting paths and compatibility with CNC routing machines. Some quick tips for preparing your design file for SendCutSend includes making sure all lines are joined, removing duplicate paths, and converting text to outlines. Providing clean, well-structured files helps prevent errors and ensures accurate cuts.

SendCutSend provides laser cutting tolerances as tight as ±0.005″ on parts under 12″ and ±0.010″ on parts over 12″, depending on the material. These tight tolerances are ideal for applications requiring precision fitment in mechanical assemblies, enclosures, and jigs. Our machines are calibrated daily, and we offer tolerance data sheets for each material to assist with your CAD modeling and GD&T planning.

SendCutSend ships produces and ships standard orders within 1-3 business days. Secondary services such as bending, anodizing, powder coating, and PEM hardware can increase the lead time on parts. When you place your order, SendCutSend’s pizza tracker allows you to follow your part through the production process and get live updates on status. You can see how secondary services may impact your lead times here.