Dolor morbi non arcu risus. Massa tincidunt dui ut ornare lectus sit amet est placerat. Ut faucibus pulvinar elementum integer enim neque volutpat ac. Accumsan lacus vel facilisis volutpat est velit egestas. Blandit cursus risus at ultrices mi tempus imperdiet. Sagittis nisl rhoncus mattis rhoncus urna neque viverra justo. Nulla at volutpat diam ut venenatis tellus in. Vitae turpis massa sed elementum. Urna nunc id cursus metus aliquam eleifend. Morbi tincidunt augue interdum velit euismod in pellentesque massa. Nunc sed velit dignissim sodales.

Dolor morbi non arcu risus. Massa tincidunt dui ut ornare lectus sit amet est placerat. Ut faucibus pulvinar elementum integer enim neque volutpat ac. Accumsan lacus vel facilisis volutpat est velit egestas. Blandit cursus risus at ultrices mi tempus imperdiet. Sagittis nisl rhoncus mattis rhoncus urna neque viverra justo. Nulla at volutpat diam ut venenatis tellus in. Vitae turpis massa sed elementum. Urna nunc id cursus metus aliquam eleifend. Morbi tincidunt augue interdum velit euismod in pellentesque massa. Nunc sed velit dignissim sodales.

Dolor morbi non arcu risus. Massa tincidunt dui ut ornare lectus sit amet est placerat. Ut faucibus pulvinar elementum integer enim neque volutpat ac. Accumsan lacus vel facilisis volutpat est velit egestas. Blandit cursus risus at ultrices mi tempus imperdiet. Sagittis nisl rhoncus mattis rhoncus urna neque viverra justo. Nulla at volutpat diam ut venenatis tellus in. Vitae turpis massa sed elementum. Urna nunc id cursus metus aliquam eleifend. Morbi tincidunt augue interdum velit euismod in pellentesque massa. Nunc sed velit dignissim sodales.

Dolor morbi non arcu risus. Massa tincidunt dui ut ornare lectus sit amet est placerat. Ut faucibus pulvinar elementum integer enim neque volutpat ac. Accumsan lacus vel facilisis volutpat est velit egestas. Blandit cursus risus at ultrices mi tempus imperdiet. Sagittis nisl rhoncus mattis rhoncus urna neque viverra justo. Nulla at volutpat diam ut venenatis tellus in. Vitae turpis massa sed elementum. Urna nunc id cursus metus aliquam eleifend. Morbi tincidunt augue interdum velit euismod in pellentesque massa. Nunc sed velit dignissim sodales.

Our founders, Jim and Jake, were always working on various projects in their garage with the tools they had on hand, often making compromises. When they tried to up their fabrication capabilities by using custom-made laser cut parts, local shops were uninterested in small orders, quoting weeks-long lead times and wanting hundreds of dollars, just for one part.

Determined to overcome these barriers, Jim and Jake sought to revolutionize the manufacturing process focusing on efficiency, accessibility, and affordability.

We know the saying that you can’t be fast, affordable and high quality, but we don’t believe it.

Jim and Jake were software guys, not manufacturers. They didn’t know “the rules” of the industry – which is why they kept breaking them.

“Why can’t we create an online laser cutting service with the convenience of Amazon?” they asked themselves. “Do you really have to sacrifice quality for speed?”

In 2018, SendCutSend was born. With dogged determination, they automated processes, created an instant quoting system, and slashed turnaround times and cost. In the end, they created the fastest way to cut and ship precision laser cut metals, from one-off prototypes to full production runs – at 10x less the cost of traditional shops.

Today, SendCutSend offers laser cutting, waterjet cutting, and CNC routing, and 10+ secondary services. They cut more than 8 million parts a year and recently were recognized as a top 5000 Inc. company.

Jim has been fascinated by mechanical things since he could hold a screwdriver and hot wheels car, and his hobbies have always included something with wheels, wings, and hundreds of moving parts. The more the better.

His entrepreneurial journey started early. Self-employed for 25 of the last 30 years, Jim started with a lawn mowing service before he could even drive, followed by ventures in graphic design, marketing, and software. SendCutSend is his latest endeavor, combining all of his loves: innovation, high-tech manufacturing, and cutting-edge software. The unusual mix of hardware and software is helping to bring an old-school and barrier-filled industry into the future.

Jim believes everything can be made better or improved (except his wife of 20+ years). As the CEO and Founder of SendCutSend, he views himself as the primary customer, deeply involved in every aspect of the company. His work is his passion—he thrives on problem-solving, R&D, continual improvement, and customer interaction. Running the company is more than a job; it’s his hobby and his greatest satisfaction. Always looking ahead, Jim has exciting plans for the next decade at SendCutSend, it’s going to be wild.

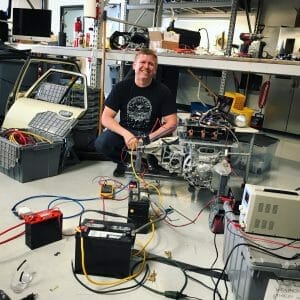

Jake has always been into fabrication and working on mechanical and electrical projects. Growing up, he spent his time building go-karts, Tesla coils, and other contraptions, always curious about how things work. With degrees in Computer Engineering and Software Engineering, he combined his love for making things with his professional skills. His blend of interests and expertise, plus the need for custom parts for an electric-powered DeLorean he was building, led him to team up with Jim to build SendCutSend.

At SendCutSend, Jake heads the engineering team, working on both the customer-facing app and the internal system that handles production, sales, and support. He’s all about making sure the software and fabrication processes work together smoothly. Outside of work, Jake uses SendCutSend for his own projects, like a reverse-trike he’s building with his daughter.

Our team invests significant time and strategic effort into ensuring our facilities operate at peak efficiency. From engineering to shipping, we are constantly enhancing our processes and features to improve performance.

Get your official SendCutSend gear here. Tees, hoodies, sweaters, and more!