Very high quality finish. Laser-cut aluminum with a bend, and with black anodized finish came out beautifully, and all nicely packaged too. Will 100% use again.

Anodizing your laser cut parts can add durability and character. The anodizing process increases corrosion resistance without adding a thick layer of material to your part.

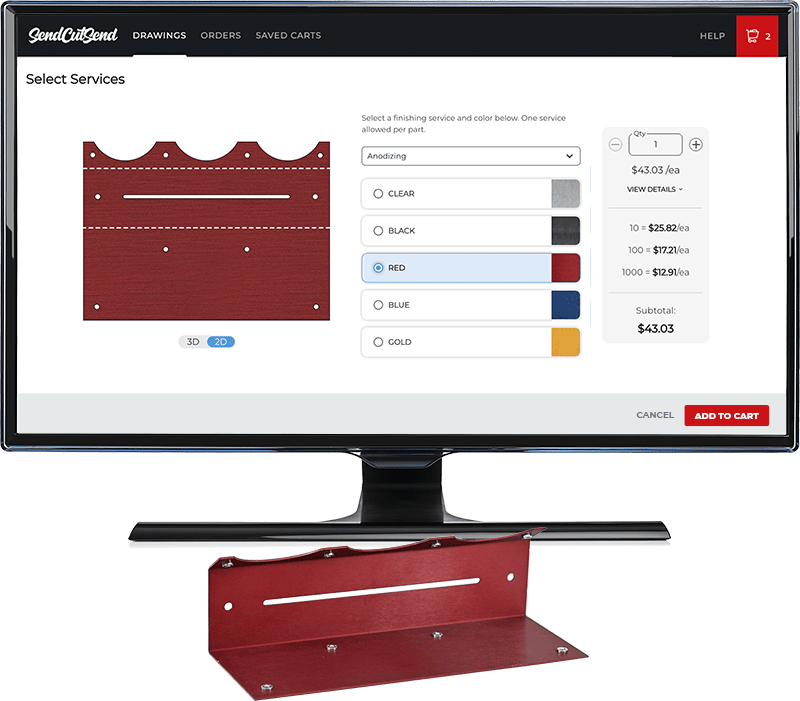

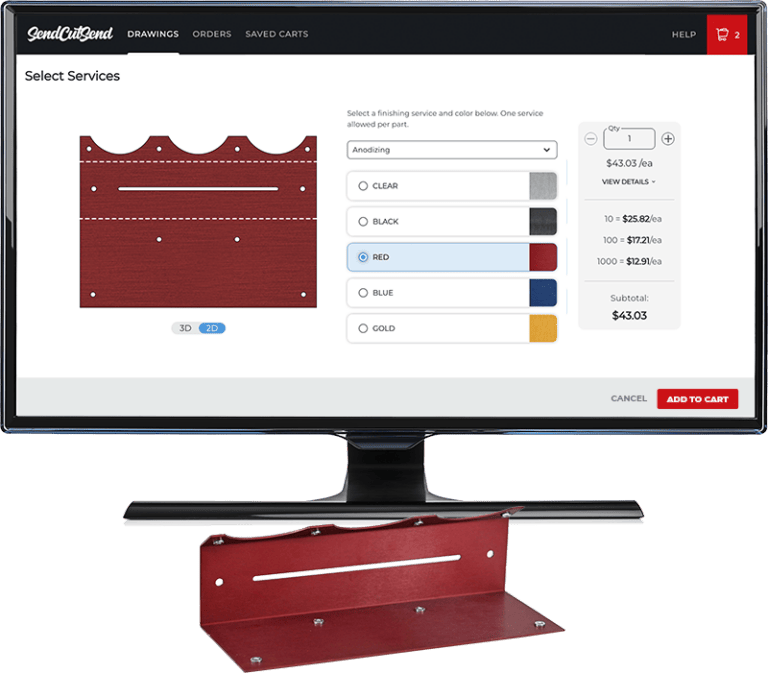

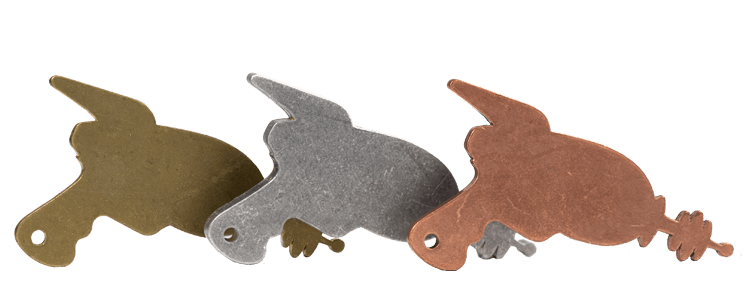

Colors may vary by batch. Click swatches to view.

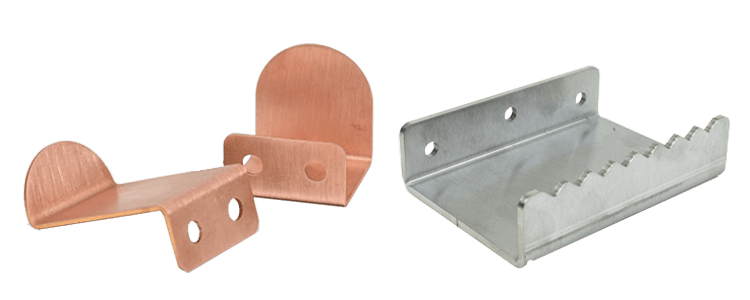

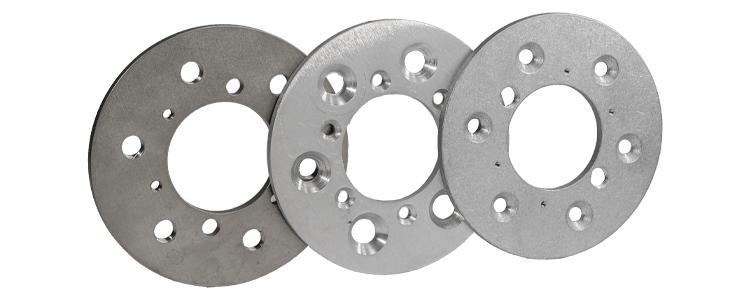

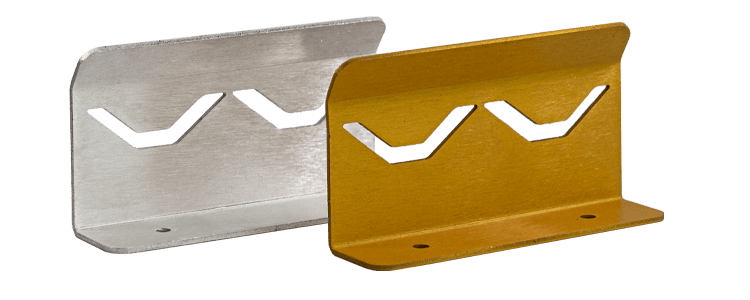

4 x 4″

Laser Cutting, Anodizing, Deburring

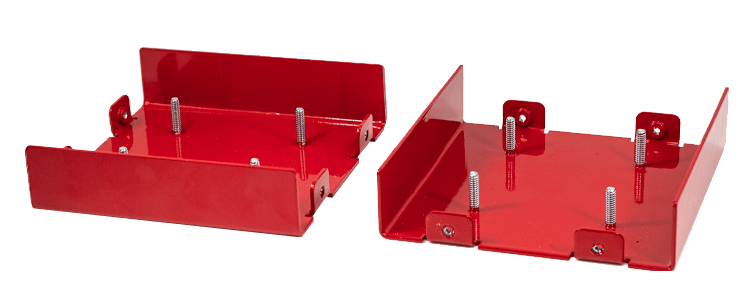

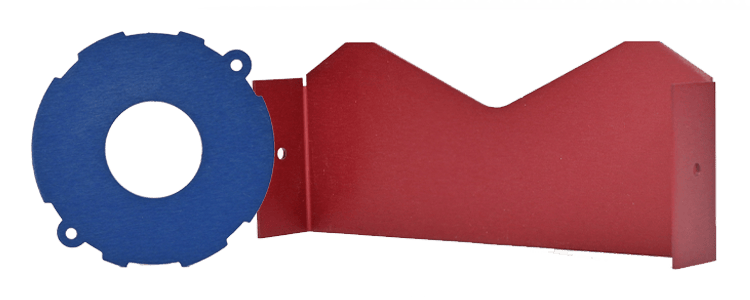

6 x 4″

Laser Cutting, Bending, Anodizing, Hardware, Deburring

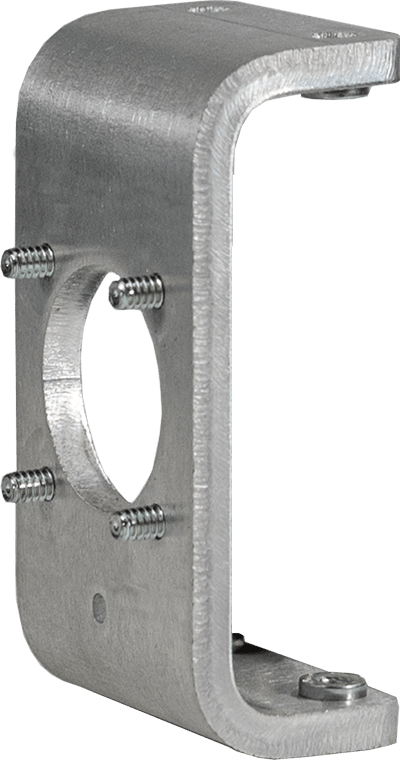

5.3 x 7.25″

Laser Cutting, Anodizing, Deburring

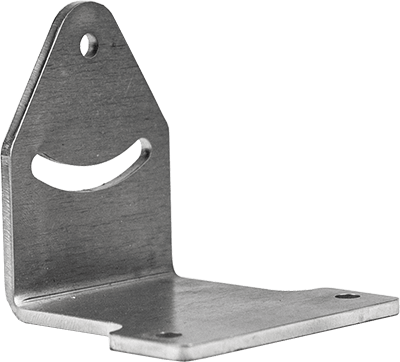

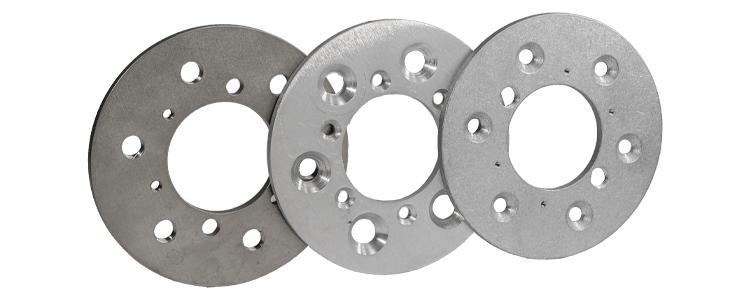

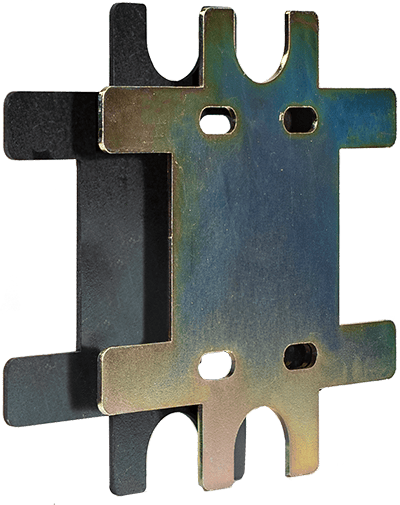

Size: 3.9 x 3.9″

Laser Cutting, Anodizing, Deburring

Size: 4 x 4″

Laser Cutting, Anodizing, Countersinking, Deburring

Size: 6 x 4″

Laser Cutting, Bending, Anodizing, Hardware, Deburring

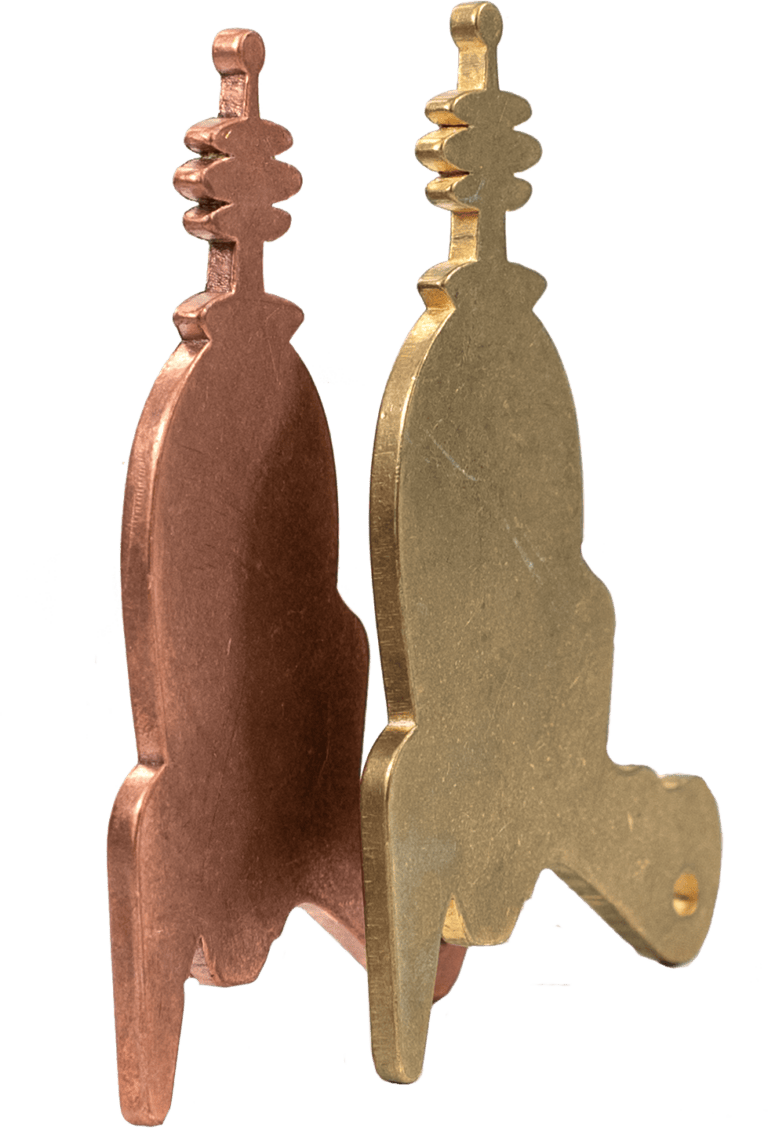

Size: 5.3 x 7.25″

Laser Cutting, Bending, Anodizing, Deburring

We accept .ai, .eps, .dwg, .dxf, step, and .stp

Upload your part, select your material, and choose your anodizing color in a matter of clicks.

Making sure your file meets our requirements will ensure you get your parts as quickly as possible.

Making sure your file meets our requirements will ensure you get your parts as quickly as possible.

Select your material, anodizing color, and quantity to see live pricing and shipping updates.

We accept .dxf, .dwg, .eps, .step, .stp, or .ai file for instant pricing. We offer our Parts Builder or Design services if you don’t have a file available.

Standard production on anodizing orders is 7-10 days with 1-3 day shipping.

We accept .dxf, .dwg, .eps, .step, .stp, or .ai file for instant pricing. We offer our Parts Builder or Design services if you don’t have a file available.

Select your material, anodizing color, and quantity to see live pricing and shipping updates.

Standard production on anodizing orders is 7-10 days with 1-3 day shipping.

Get started on your project with the click of a button. Whether you have a CAD file, a sketch, or just an idea.

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your material.

2-4 days standard production

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 12 materials

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 3 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+7-10 days | 9 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

We take pride in our customer service, quality, and continual innovation with new products and services. You’re in good hands with SendCutSend.

Top Quality Store

Please note: Pricing examples on our website are provided as general estimates and may not always reflect current prices. While we strive to keep these examples accurate, uploading your file is the best way to see instant current pricing.