from

before rebate

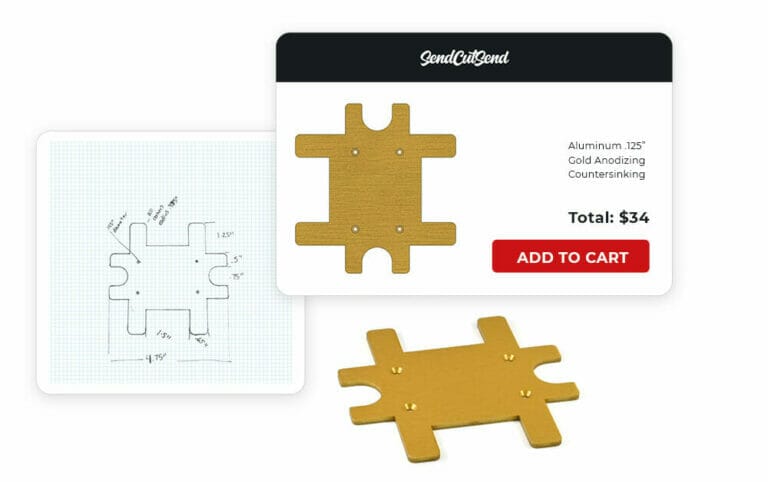

Pricing starts at just $19, based on the complexity of your part. This fee includes two FREE revisions prior to ordering. Additional revisions require a fee of $5 to begin.

If your order is $100 or more, we’ll give you a rebate for $20.

Please note: Design requests that have been paid for but are awaiting information or approval longer than 30 days will be closed and require additional payment to reopen.

Two services to choose from starting at $49:

Upload a high res photo of your sketch on graph paper, or send us a photo of your template to be converted.

If your drawing or template request meets our requirements, we’ll send you a payment link to initiate the conversion. Pricing starts at $49. Revisions will be handled directly via email.

Your part will be ready to buy in one easy click. Once you purchase, you’ll receive a tracking link to follow your order from production to your doorstep.

We’ve provided tools and guidelines to make our services as smooth as possible. Click the links below for useful tips, tricks, and downloads.

We prefer drawings be provided on graph paper. Don’t worry, if you don’t have any on hand, you can download it here.

Refer to our quick list of our requirements and limitations to get your first design service order started.

We’ve provided a comprehensive guide with examples so you can start your first design with all the knowledge.

Not sure what material best suits your idea? Don’t worry, we’ve compiled a list of the best materials for various use cases.

If your idea does not meet these requirements you can check out our list of Design Partners to find someone that can assist you

We’d be happy to help you with material selection! We’ll ask questions about the project and assist you in selecting a material for your project. Please note, we do not offer any engineering services or guidance related to strength, longevity or safety.

No. When the design process is complete, we’ll send you a link that will allow you to add the part to your SendCutSend parts library, but direct CAD downloads are not available.

Yes! Your design, concept, and IP are still yours, and you are free to use the file we create as you please for personal or commercial use. The CAD file that is created is retained by SendCutSend, and available for your exclusive use.

No. We focus on industrial parts, and as such, we do not offer any text design work.

Absolutely! We’d be happy to help you create a part with bends! We’ll need to know your desired outside dimensions, bend angle, and bend direction in order to get started.

If your idea isn’t a good fit for our Design Services, we have list of Design Partners that you can browse to find someone that can help.

Our Design Partners are versed in our requirements and limitations, and have been approved by our team. We assure you’ll be in good hands.

Check out our list of design guidelines for all our services and operations to ensure your ideas meet our requirements.

"*" indicates required fields

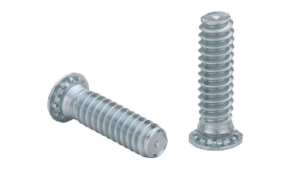

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

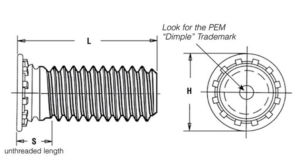

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |