Get parts as low as $0.70 per bend with bulk pricing. Save up to 70% with quantity discounts! We calculate quantity discounts based on several factors including material, operation type, number of operations on each part and number of duplicate parts. Our app will automatically provide quantity discounts based on your order.

Check out our processing page for information about typical lead times for parts with bending and other services. We provide free 1-3 day shipping for standard US orders over $39 (higher quantities may require additional time). Most bent parts will ship ground as they will exceed 2″ in height when packed.

Before you start dreaming up your next project, you’ll need to know some of the metal and plastic bending limitations.

Bending plastic is different! See our complete list of polycarbonate bending considerations.

Bending specifications like bend radius and K factor are set per material thickness and we do not offer custom bend radii at this time.

Be sure to design using our material bending specifications so your parts turn out as expected! You can confirm bending specifications in our Material Catalog or Bending Calculator.

Using Autodesk Fusion or SolidWorks? Download our gauge tables to apply the latest specifications with a few clicks.

Bent parts will have different dimensional and bend angle tolerances depending on the part size and material type.

Keep tolerance stackup for multiple bends in mind. Learn more about bending tolerances and how to plan accordingly.

While we’re happy to bend your parts to your hearts’ desire, there are some bends we don’t offer:

At SendCutSend we form sheet metal and plastic with air bending.

Learn about air bending, its effect on bend radii, and polycarbonate considerations.

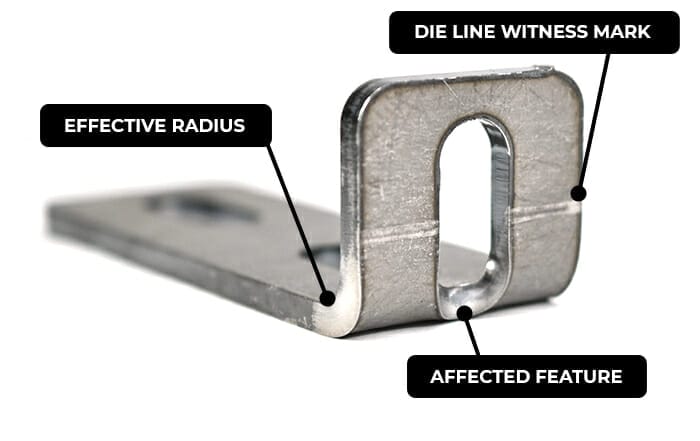

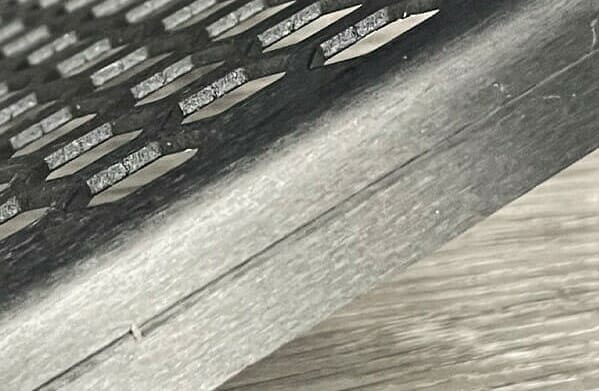

Die lines are the full extent of the width of the tooling, or die, that we use to form parts.

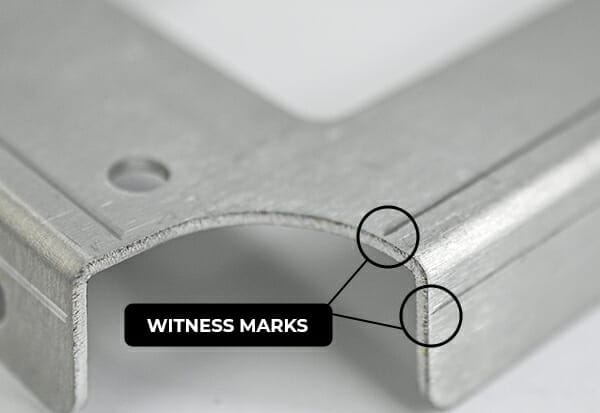

When a part is bent, witness marks are left where the die makes contact with the part. These points of contact are what we refer to as die lines.

When cut features fall within the die lines or bend area, they will be distorted during the forming process when the material is stretched.

Learn how to avoid feature distortion in our Bending Deformation Guidelines.

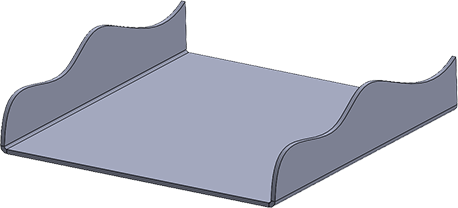

While designing parts with flanges that meet at a corner, keep in mind that collisions can happen. Our 3D bend previewer is a great reference tool and we have specific corner clearance guidance available.

Please note, we cannot guarantee that the preview will match your finished part perfectly. Be sure to select the material you’re designing with and use the specs from our Bending Calculator.

Here are the basics you’ll need to know before you send us your first file for bending. If you have any questions, feel free to contact support.

Make sure the part design you upload for bending is either a 2D vector file (.dxf, .dwg, .ai, or .eps format) or a 3D .step or .stp format file. You will be able to view your bends in a 3D model during the checkout process to make sure the angles and flange orientations are correct.

| SOFTWARE | FORMAT | BEND LINE |

| Fusion | .dxf, .step, .stp | Solid line (default) |

| Adobe Illustrator | .ai | Solid, separate color from cut lines |

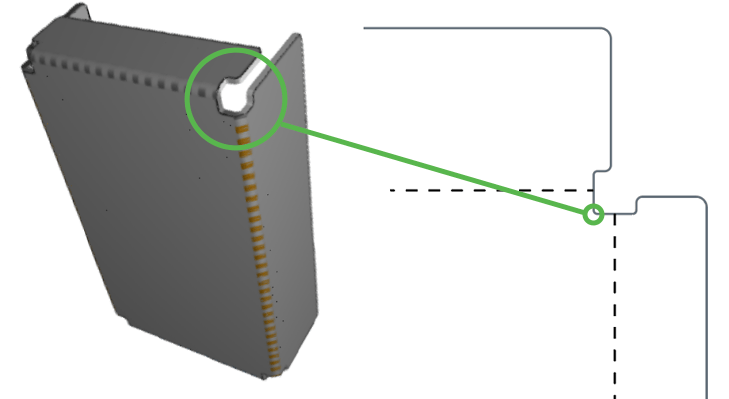

| SolidWorks | .dxf, .step, .stp | Dashed line (not hidden) |

| AutoCAD | .dxf, .step, .stp | Dashed line (not hidden) |

| CorelDraw | .eps | Solid, separate color from cut lines |

| Inkscape | .eps | Solid, separate color from cut lines |

Please upload either a 2D .dxf, .dwg, .ai, or .eps format vector file or a 3D .step or .stp format file with your part design.

Ensure your part is set up using the bend radius and K factor specifications for the material thickness.

If you design your parts in non-CAD software (Adobe Illustrator), please send us the original (native) .ai file.

We’ll take care of the conversion on our end. While we accept .ai and .eps files, it’s critical that your bend lines are parallel when uploaded from these software or the file will delay our process.

For the fastest turnaround on your order, we recommend designing your parts in CAD software.

To learn more about design guidelines for laser cut sheet metal, see our Laser Cutting Guidelines.

For CNC routed polycarbonate design guidelines, please see our CNC Machining Guidelines.

Working in Solidworks? Download our custom bend tables to specify exact bend allowances, bend deductions, bend radii, and K-factors so your file is tailored to our manufacturing processes.

Autodesk Fusion users can import SendCutSend sheet metal rules by following our gauge table guide.

If you upload a 2D vector file, we will use the flat .dxf, .dwg, .eps, or .ai file (if you use Adobe Illustrator) for cutting and bending, so please indicate bend locations in your drawing using a line. Bend lines should mark the center of each bend.

See our troubleshooting tips if your bend lines don’t show up after uploading your file.

During the ordering process, you can specify bend angles for each line. You will receive an error message in the app if your bend line is missing or insufficient.

Reference our bending export guides for assistance exporting cut-ready files.

If you plan to submit a STEP/STP format file, see our 3D File Guidelines.

Ensure your sheet metal rules are set up with SendCutSend’s specifications for bend radius and K factor for the material desired.

Tip: you don’t need to worry about bend lines if you’re uploading a STEP/STP file. Model your part, set your bend definitions, save your file, and upload for instant pricing.

Learn how to configure STEP file bends when pricing your parts.

We make the parts you send us! Use the correct material specifications from our website to ensure your bent parts turn out as expected.

The minimum flange length will change depending on what material and thickness you use. Please reference your chosen material in our Material Catalog to see the correct dimensions under Material Details.

Learn how to measure flanges and find specifications for materials thicknesses.

The maximum flange length for 3-4 sided box bends and perpendicular flanges bent in the same direction will depend on the material choice and whether hardware will be installed. With hardware, the maximum flange length for box bends is 3.00″.

Learn more about maximum flange lengths on 3-4 sided box bends and perpendicular flanges.

The bend angle is measured on the outside of the bend. In the illustration below, you will see that the acute bend is being called out as 130°.

Learn more about bend angle callouts and how to enter bend definitions when ordering.

Note: the bend angle limits and bend radius for your part can be found on the material page. We do not offer a custom bend radius.

However, the 2:1 ratio rule for sheet metal parts can be flexible for thinner materials that meet specific criteria.

Learn about exceptions to the 2:1 base-to-flange ratio rule for sheet metal u-channel parts.

For u-channel bends in polycarbonate, the base must be at least 3 times wider than the flange length (3:1 ratio).

Window bends are allowed up to 90° for sheet metal and polycarbonate parts. More acute angles require review by our team.

Learn about our window bend design requirements.

Joggle bends are allowed up to 90° for sheet metal parts only. You can find the minimum and maximum joggle flange values on the specification charts for your chosen material.

While we do allow for irregular shapes for your flange, we will need a flat piece to bend. To do this, add tabs to make a flat surface parallel to the bend.

Ensure your tabs are long enough for your part and include enough connecting bridges. See our complete guide on setting up breakoff tabs for odd flanges.

To reduce bulging in the corners of your bent parts and prevent tearing, incorporate bend relief notches into your design.

These notches allow for less stress on the inner radii of the flanges and will help keep the corners of the bends from interfering with the base material.

Learn more about our bend relief requirements for polycarbonate and sheet metal parts.

If you need some of your parts to “mirror” others, split mirrored parts between separate line items and specify opposite bend directions.

You can use the Duplicate item button in your shopping cart to expedite this!

Set your design file up with our bending specifications for the material thickness you need.

This prevents errors and ensures your parts turn out as expected since the bend radius, K factor, and other critical specifications are set for each material thickness.

Bends on a common axis need to be joined, as in the example shown here. If they are not joined, each bend will be seen individually.

We are unable to bend intersecting lines that do not have separate flanges.

Certain designs require bend relief to avoid damage to the part. Without proper relief, a part cannot be bent accurately. This is a critical consideration for polycarbonate parts since the material is prone to cracking. Check out our Bending Deformation Guidelines for more information.

We cannot form incomplete bends (for example, one half of a part.)

A bend must be complete and extend all the way across the area to be bent.

For most materials, the minimum flange length should be met for at least ~50-60% of the bend’s length on both sides of the bend. This ensures enough material makes contact with the press brake’s tooling to provide adequate support during the forming process.

Thicker materials (especially 0.187” – 0.250”) will need more material contact to create sufficient support. Learn more in our guide to preventing deformation.

Although metal and plastic forming is a deeply complex process, we here at SendCutSend aim to make part bending as easy as possible. Questions? Reach out to our support team.

Happy bending!