SendCutSend is propelling the manufacturing industry into the future

(RENO, Nev.) – SendCutSend has had one of their biggest years on record, thanks, in large part, to their loyal customers. With more than 10 million parts shipped, more than 1,000 five star reviews and more than 150,000 customers, the company continues to reinvest to bring the same accuracy and speed to one-off prototypes or multi-thousand part production runs.

“We’ve watched small businesses start at the kitchen table, move to a garage, and now have full fledged warehouses,” said Jim Belosic, CEO of SendCutSend. “Many have been with us since our inception and we are growing right along with them to offer the same level of quality and turnaround for their larger runs.”

In the last year, SendCutSend has reduced base production time by 50%, now at just two to three days, and has doubled employee headcount with more than 180 employees across the United States. The recent addition of a new $1.3M high power fiber laser and two additional state-of-the-art CNC press brakes will bring even more speed to lead times.

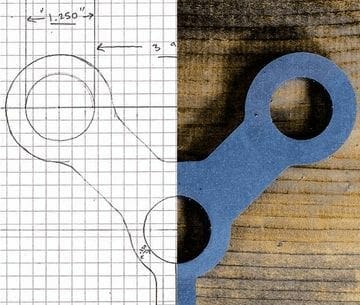

That accessibility is allowing businesses to iterate faster and quickly, accurately and cost effectively cut one part or thousands, revolutionizing the way businesses are approaching prototyping and production.

Putting advanced sheet metal fabrication in the hands of anyone with a CAD file. SendCutSend is also making it easier to create final parts in one place by adding CNC bending, hardware insertion, powder coating, countersinking, tapping, plating and anodizing services. As well as offering more than 165 materials, including metals, composites, plastics, woods, and boards.

As SendCutSend continues to expand its services and capacity, the company remains committed to empowering businesses and individuals to innovate and grow.

###

Media Contact: Nicole Latva, nicole@sendcutsend.com