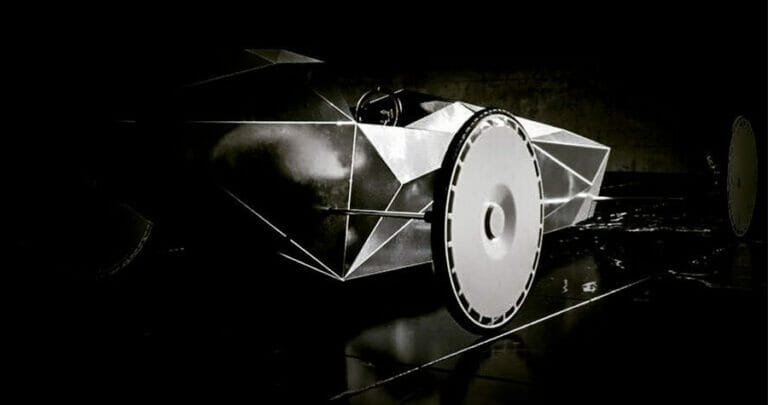

Custom vehicle demonstrates modern AI-enabled manufacturing techniques

(RENO, Nev.) – Nevada-based rapid manufacturing company, SendCutSend, will unveil a custom, turbine-electric powered streamliner at this year’s SEMA Show in Las Vegas, Nev.

“Jet-A-Send” was developed by SendCutSend’s R&D team to demonstrate on-demand manufacturing services and technology. The turbine-electric powered streamliner is constructed entirely of materials, processes, and services available to the public via sendcutsend.com.

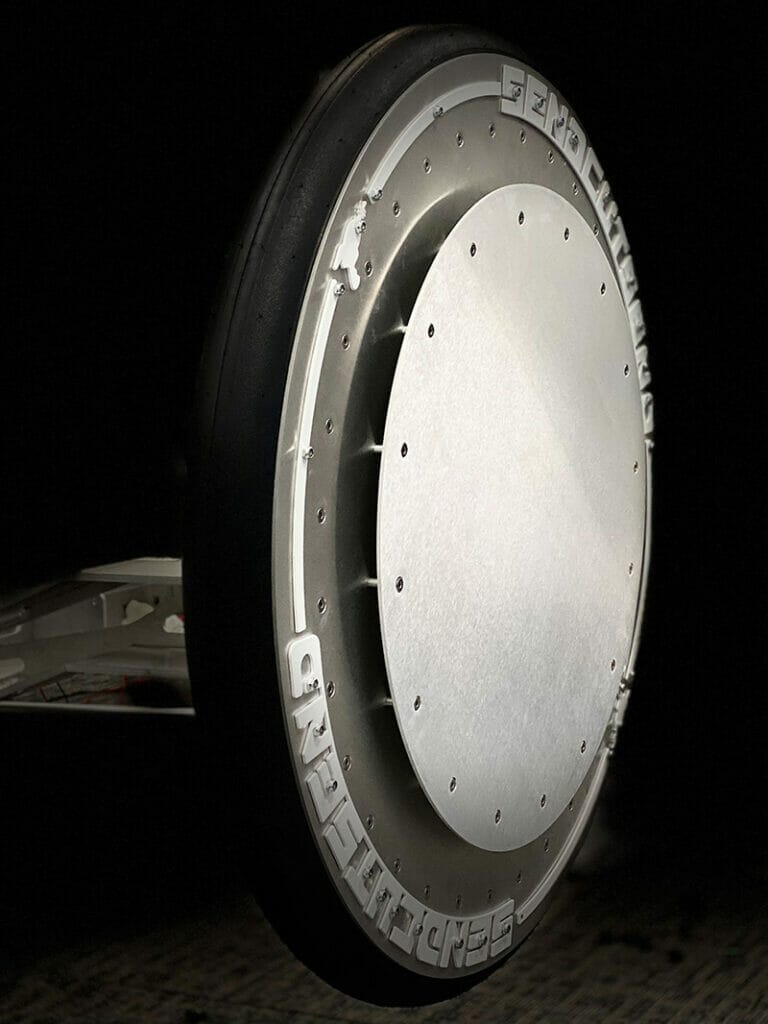

With about 190 hours in design and only 28 hours in assembly, the vehicle features a laser-cut stainless steel body and aluminum chassis which uses high-precision CNC bending, tapping, and countersinking. It also demonstrates the ease of use and efficiency of SendCutSend’s rapid manufacturing model. The finishes on Jet-A-Send feature clear, red, and black anodizing; yellow and black zinc plating; and various raw materials including carbon fiber.

A 10hp JetCat Turboshaft provides electrical power to onboard lithium batteries, which in turn power the. three-phase, 25 kW AC motor by Electro & Company. The turbine-electric motor gets 300 miles per gallon (Jet A, Kerosene, or Bacardi 151). Jet-A-Send weighs in at roughly 388 pounds without a driver.

SendCutSend was launched in 2018 by Jim Belosic out of a need for access to manufacturing, quickly and affordably. The nationally recognized company has continued to innovate with a proprietary app, Parts Builder, and instant pricing. Now offering more than 250 materials and thicknesses and post-processing services including anodizing, bending, countersinking, powder coating, plating, tapping, and deburring, everyone from students to Fortune 500 companies now have access to high-tech manufacturing equipment at an affordable price.