Based in the U.S., Katalyst Space is building technology that sounds like science fiction: a fleet of robotic spacecraft that upgrade and extend the life of satellites in orbit.

As our skies fill with satellites from governments and private companies alike, a few questions become increasingly urgent: how do we make satellites that aren’t single use? How do we upgrade or repair satellites once they’ve been put into orbit, so that they stay in orbit longer?

Katalyst’s answer: we upgrade and fix them. Even while they’re hundreds of miles above Earth.

That’s where SendCutSend comes in. When Katalyst’s engineers are designing, testing, and refining their space-bound technology, they turn to SendCutSend for rapid prototyping and high-quality custom parts.

One of their current projects? Helping NASA rescue a telescope that’s about to fall out of orbit. But to build the tools and tech needed to perform satellite surgery in space, Katalyst needs precision parts, fast.

We sat down with the Katalyst team to learn how they’re using our services to push the boundaries of what’s possible.

5 Ways Katalyst Space Uses SendCutSend to Power In-Orbit Satellite Upgrades & Repairs

1. Rapid Prototyping of Custom Parts

Space upgrades and repairs aren’t exactly plug-and-play. Katalyst is inventing new tools and systems that often have no blueprint. To validate these ideas, they need to build and test one-off components.

That’s why they rely on SendCutSend’s no-minimum-order policy and quick turnaround times. Whether it’s a bracket, plate, or housing, they can get custom-cut parts delivered quickly, so they can test ideas here on Earth before sending them into orbit.

2. Battery Energy Management Systems

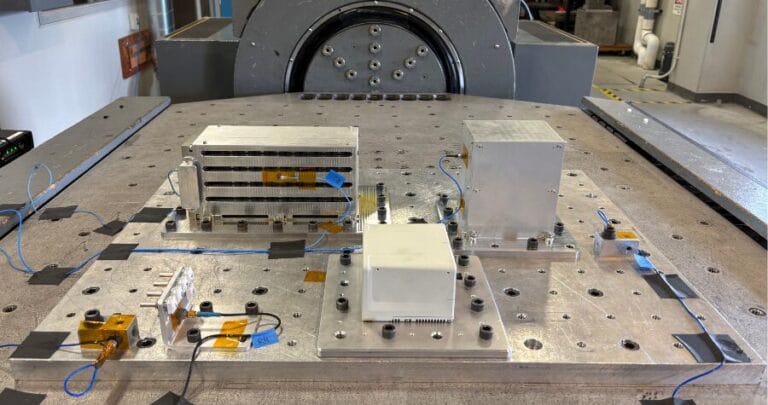

Keeping systems powered in space is no small feat. Katalyst builds advanced battery management systems for its orbital robots and many of the metal housings and enclosures for those systems are made through SendCutSend.

They even built a large-scale performance test rig for their robotics using large sheet metal panels from SendCutSend.

These components need to be precisely cut, bent, and drilled to integrate seamlessly into energy systems that operate in extreme environments. No pressure, right?

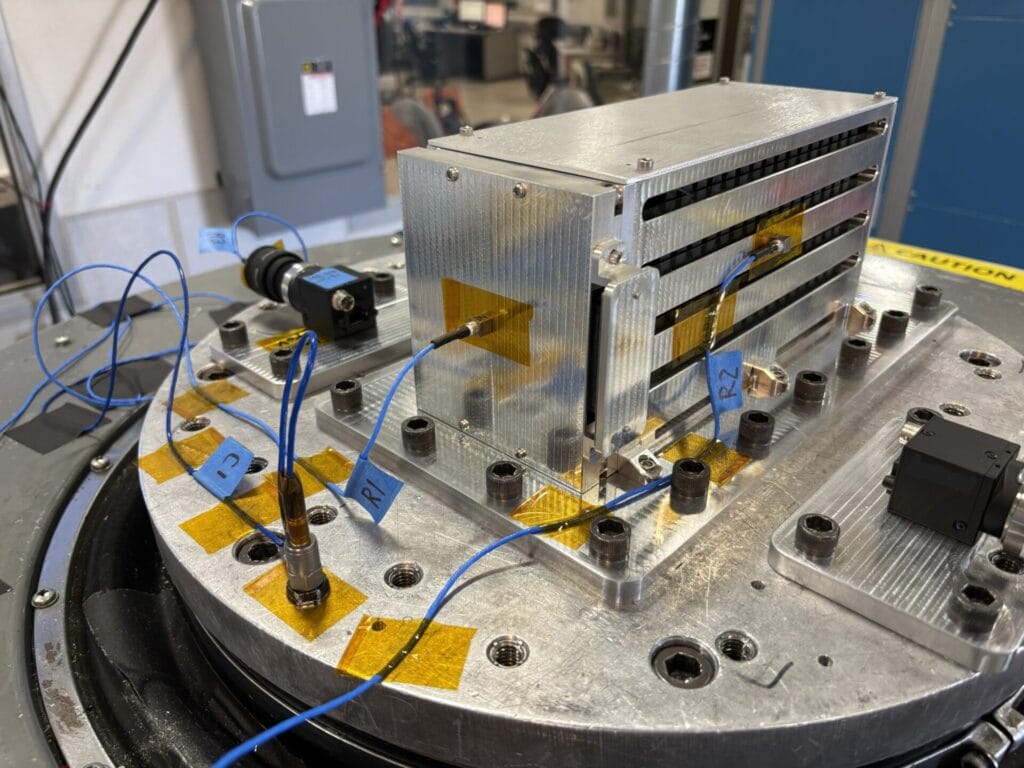

3. Test Plates for Potentiometers

Some of the parts Katalyst orders serve double duty, like the test plates they use for potentiometers. These plates are used to mount and protect potentiometers during testing and in live operations, sometimes even functioning as the control interface.

It’s a perfect example of how a small, simple part can play a crucial role in a complex system.

4. Custom Avionics Components

Avionics are the nerve center of any spacecraft. From housing sensitive electronics to supporting structural components, Katalyst uses SendCutSend to fabricate parts that help their avionics systems survive the stresses of spaceflight.

With custom-cut and -formed pieces made to exact specifications, these parts aren’t just functional, they’re mission-critical.

5. Mechanical Systems for Satellite Repairs

From gaskets and gears to mounting plates and mechanical linkages, Katalyst’s repair systems require a wide range of metal, composite or plastic components. Many of these are prototyped and even produced using SendCutSend’s manufacturing capabilities.

With so many moving parts (literally), it’s essential that everything fits perfectly and performs reliably. We’re proud to be a part of that precision.

Helping the Future Take Off One Part at a Time

At SendCutSend, we’re in awe of what American companies like Katalyst Space are achieving. Their work is not just futuristic: it’s reshaping how we think about sustainability and engineering in space.

And while not every project we support is destined for orbit, we believe the same ingenuity that’s fixing satellites can also power the next big breakthrough whether it’s in aerospace, robotics, or right in your garage.

Got a project that needs custom parts? Whether you’re upgrading satellites or building a robot dog, we’ve got you covered.