If you’re new to ordering custom, laser-cut metal parts you’re probably wondering if your parts will come out exactly as you envision them and how will you know the laser will interpret your design to its exact specifications?

No matter what use your finished piece serves, lead-ins and micro tabs help to keep your design accurate while ensuring their safe arrival at your door. Lets talk a little bit more about lead-ins and micro tabs and what you need to know before uploading your design to SendCutSend.

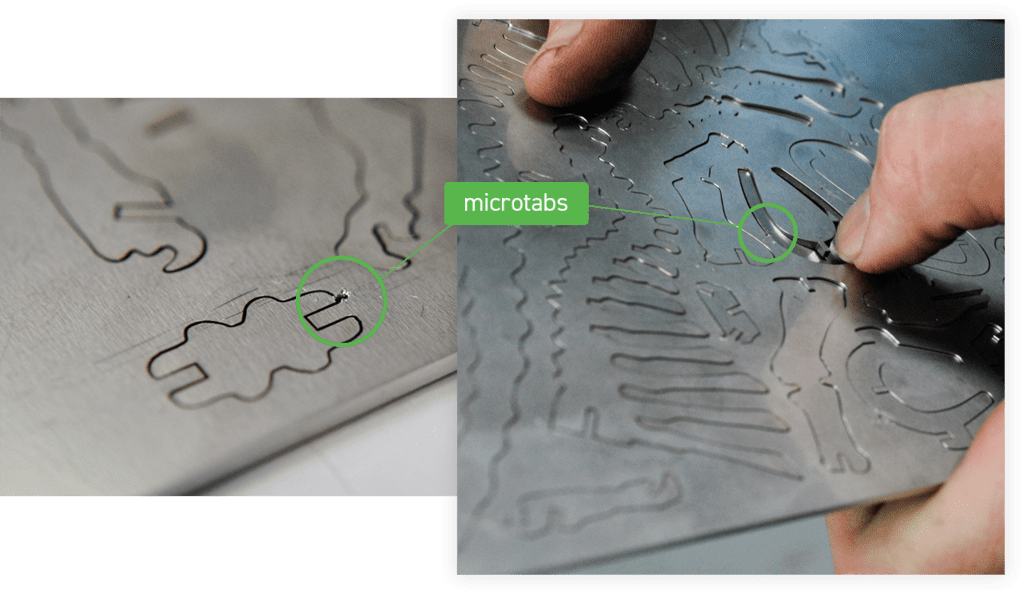

What are Micro Tabs?

Micro tabs are really tiny tabs of metal that are factored into your design to keep your parts from falling out of their metal “nest”. When the laser pierces the metal, it makes its way around the outer line of your design and then stops just short of connecting the dots. This is how a micro tab is created – the 0.010”- 0.015” space of metal between the unconnected dots keeps your parts within their metal nest until they’re removed, which helps ensure parts aren’t lost before being packaged and shipped to your door.

What are Lead-ins?

Lead-ins are where the laser pierces the material to begin cutting your design. We make sure to put the lead-in on the outside of the initial cuts to ensure your design isn’t affected, but any interior geometry that needs to be cut out of your design will need its own lead-in. This is the biggest reason for our minimum geometry requirements.

For example, on .125″ (3.1mm) 5052 Aluminum, the smallest hole we could cut would be .044″. On geometry any smaller than that, the point of entry for the laser would blow out the intended design. The lead-ins on such small geometry can do anything from show burn marks to completely ruin the interior designs of the part.

It’s important to not pre-nest your parts (put multiple designs/parts on the same file) because our automated system cannot offer custom tab or start/stop placement options. And as always, make sure to read all our laser cutting and materials guidelines to stay up to date on the tolerances for your chosen material.

Should You Add Lead-ins and Micro Tabs to your Design?

Nope! Design your parts to the exact specifications you need and leave the rest to us. Our software will add in the lead-ins and micro tabs in their most optimal spots. Now that you’re up to speed on lead-ins and micro tabs, check out our blog for other tutorials and design tips. Have questions or need a custom quote? Give our support team a shout anytime.