2022 brought more accessibility, more power, and more services.

(RENO, Nev.) January 2023 – In 2022, SendCutSend had its largest year of growth since its 2018 inception. The online laser cutting company added international shipping to Canada, five new services, dozens of additional materials, and increased laser and bending power.

“Last year we really focused on power and services – more power means faster production and getting those parts to our customers faster,” said Jim Belosic, CEO of SendCutSend. “We look forward to bringing even bigger things to our customers this year.”

More Accessibility

Canadian customers now have access to affordable laser cut parts with no minimum quantities, parts starting at less than $1 ($39 minimum order), 2-4 day production, instant pricing, and a flat rate shipping of $19 on standard orders.

SendCutSend’s app received 302 major improvements (and about 5,000 small ones). Customers can now batch upload up to 10 drawings at a time, track orders through more than 12 production steps and review CNC bent parts with advanced 3D previews. Through improved nesting strategies SendCutSend is also reducing waste (and cost to the customer).

The team worked on improving all aspects of the production process including shipping. Shipping is now faster and available seven days a week to residential addresses.

More Power

SendCutSend added 21 kilowatts of laser power to the cutting arsenal bringing the total cutting capacity to almost 60kW. In addition, the facilities increased CNC bending capabilities by 160 tons of bending power.

These improvements sped up production and got parts out the door even faster. The additional power meant more than 750 tons of material was processed and shipped to our customers.

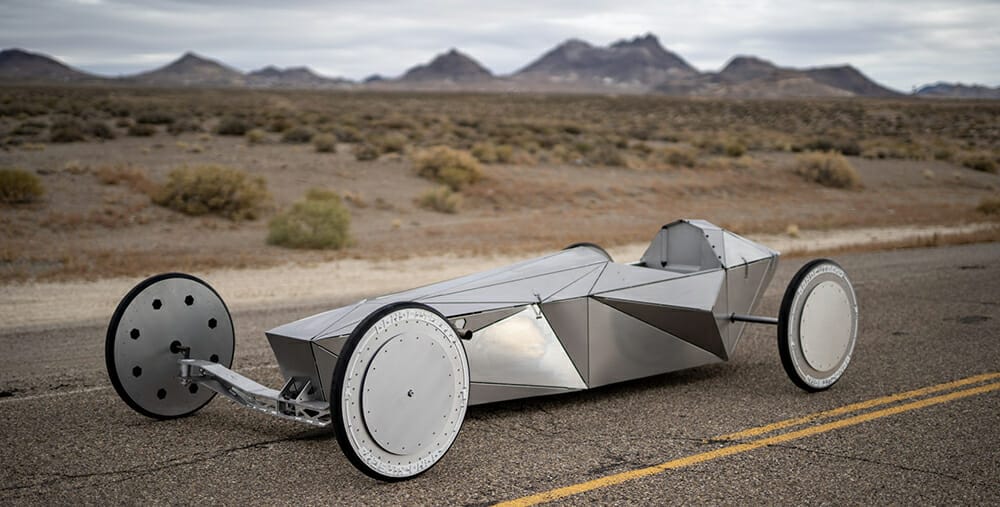

Speaking of power, SendCutSend also unveiled a custom, turbine-electric streamliner, dubbed Jet-A-Send, at the SEMA tradeshow in Las Vegas.

More Services & Materials

Perhaps the biggest part of 2022 was the plethora of new services. From waterjet cutting to powder coating, to hardware insertion (PEM hardware), SendCutSend is on its way to being a one-stop shop.

With cutting services expanding to include Waterjet (joining Laser and CNC Routing), customers now also have access to seven post-processing services including Anodizing, Bending & Forming, Countersinking, Hardware, Powder Coating, Plating, and Tapping.

New additions were also made to the materials list: G10 (FR-4 grade), Chipboard, Hardboard, and 316 Stainless Steel.