As a loyal SendCutSend customer, Mike Burroughs already had experience with our online laser cutting when he decided to do something unthinkable: put a Honda engine in a Ferrari. Documenting the reengineering process on his YouTube channel, Mike’s Honda-Swapped Ferrari made a splash online and at SEMA 2022. Keep reading to learn how he used SendCutSend to make it happen!

At a Glance

- Industry: Automotive

- Services: Online Laser Cutting and Sheet Metal Bending

- Summary: With countless complicated parts and a whole car to completely reengineer, Mike Burroughs had his work cut out for him when he decided to take on swapping out a Ferrari engine with Honda K-series. Facing hundreds of hours of iterative design, Mike knew he couldn’t make all the parts himself or wait on them to be made.

- Solution: Mike turned to SendCutSend to get high quality parts laser cut efficiently and at an affordable price. The Ferrari is now a smashing success and he is continuing to improve on his own changes even today.

Introducing the K24 Ferrari

The Ferrari 308 is one of Mike’s favorite cars. Its sleek body and reliability are characteristic of the Italian manufacturer, with some used models currently selling for up to $115,000. However, manufactured and sold between 1975 and 1985, the drivability of the car was a product of its time and left much to be desired in the way of power, speed, and handling.

Cue StanceWorks.

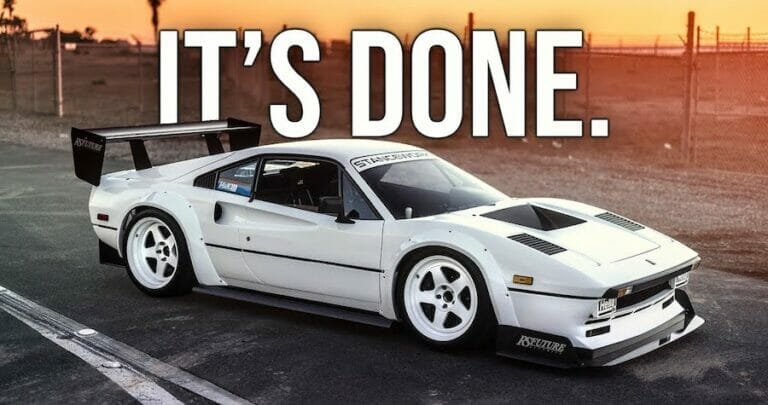

Mike wanted to take this dream car and bring it back to life with a twist: a new Honda K-series engine and some world-class suspension reengineering. With a deadline for SEMA 2022 and an eager audience watching, Mike put everything he had into making the “K24 Ferrari,” as he has dubbed it, a reality.

Taking the Ferrari 308 to the Next Level

Over 2 years ago, Mike purchased a used 1981 Ferrari 308 GTBI. With just 38,000 miles on it and in amazing condition, there was little work needed to get the car up and running to its original standards. But Mike wanted to do better than that, so with a short video posted in December 2020, he introduced the Ferrari to his YouTube channel as his next project car with the goal of removing the original engine and replacing it with a Honda K24, revealing the substantial redesigns that would have to take place to make the project work.

“This is one of my all-time favorite cars. It’s been a dream of mine for awhile to work on one, but as a product of the 1980s Ferrari brand, what lies underneath the hood requires substantial reengineering. I knew it would be a big challenge.”

With a myriad of new engineering challenges cropping up at every turn, Mike documented the full engine swap process and part redesigns on the StanceWorks YouTube channel. With 2 years worth of videos showing the highs and lows of such an ambitious project, there is plenty to learn from Mike’s process.

But when the Honda K24 roared to life from inside the Ferrari as Mike drove it onto the floor at SEMA 2022, it was obvious to all around that the countless hours of work Mike poured into the car were all worth it.

“This project was the star of the show at SEMA 2022. It was a longtime coming and people who followed it were excited for the reveal, but there were also plenty of people surprised to see a car from the 80s roll into a show where you’d normally only see brand new vehicles. It got a lot of attention and the response to the car was awesome!”

Back to the Drawing Board!

Although the engine swap is the most prominent part of the project, much of the car required significant reengineering to handle the new engine and make it drivable. The subsystem Mike is proudest of is the suspension, which was a complete redesign and took a lot of learning on Mike’s part.

“There are 8 control arms in this suspension: 4 upper and 4 lower. Over the course of prototyping, revisions, and final designs, I built at least 30 control arms total. I would reach a new milestone and then have to go back to the drawing board with something new to change. There are over 6 months of work in the suspension alone.”

The suspension wasn’t the only subsystem that went back and forth from the drawing board to the car. Many of the solutions Mike engineered for the Ferrari were made through trial and error as the whole project was unprecedented.

One of the more infamous chapters of the build vlogs on StanceWorks’ YouTube channel documents the explosion of the custom designed and manufactured intercooler. It exploded while the car was hooked up to a Dyno for testing, creating a new challenge for Mike and one of the most viewed videos in the series simultaneously. Not one to shy away from a learning opportunity, Mike followed up with a video designing a brand new intercooler with thicker walls and having the sheet metal parts cut right here at SendCutSend.

Using Online Laser Cutting To Revise and Build

Mike has been using our online laser cutting services for his car projects for years, so he’s no stranger to our processes. In several of StanceWorks’ earlier projects, Mike had tried to use local waterjet and laser cutting companies to manufacture his car parts. He would have to put projects off until he could put together a large enough order because they couldn’t do runs under $250, or he would have to supply his own material and spend a whole day sourcing and dropping it off. It just wasn’t worth it.

Mike initially saw another maker on YouTube using our sheet metal cutting and bending services and decided to give it a try for himself. After that, he was hooked and has used SendCutSend in nearly every project since.

“SendCutSend has allowed me to streamline my process and make builds like the Ferrari swap possible. Any time I need to make a revision, I just open up Autodesk Fusion, make a couple changes, and send the part off for machining instantly. There is no way the car would be finished yet, and moreover the car would not be the quality it is, without SendCutSend. With SendCutSend, I am able to bring a better, bigger, and larger-than-life car into reality.”

Advice to makers and car enthusiasts

Mike is one of the biggest advocates for makers and car enthusiasts online, and he encourages everyone to pick up something they’re passionate about and get to work. His advice to people wanting to start on a project car is to learn how to CAD. With the recent revolution in making online CAD software more accessible, there are plenty of programs that are easy to learn and simple to use with the help of some tutorials.

“Learning to CAD was a game changer for me. It has upped the quality of everything I do, so my advice for you is to learn how to design in a digital space and then use SendCutSend to help bring those designs to life.”

If you’re looking to start using SendCutSend for your personal projects or small business, be sure to check out our other case studies and customer features where we talk to people just like you who have created something awesome using our services. Our online laser cutting and waterjet cutting services can help get you started, with plenty of awesome additional sheet metal services like bending, countersinking, anodizing, and more.

Keep Up With StanceWorks and SendCutSend!

We love the work Mike is doing with StanceWorks and even as he begins race prep for the K24 Ferrari, we can’t wait to see where his next project car takes him. You can watch more updates on the K24 Ferrari and follow along with his next projects on the StanceWorks YouTube channel. If you want to catch small updates and see some gorgeous car shots, be sure to follow the StanceWorks Instagram page too!

–Are you a maker influencer or small business owner with a cool project to show off? We want to hear about it! Fill out a Partner With Us form and we’ll be in touch.