Due to their material properties, and the relative ease with which they can be made, brass and bronze are two copper alloys that have been an important part of civilization for over 5000 years.

Today, not only are brass and bronze preferred media in architecture and the creative world, but both metal alloys are still heavily used commercially for marine, defense, aerospace, electronics and consumer goods industries. Let’s take a closer look at how you can leverage SendCutSend capabilities for brass and other great materials.

In this article, you will find useful information on the main differences between brass and bronze, considering their composition, material properties, and by looking at example applications.

We’ll also cover some of the history, why these alloys of copper are still in use, how to tell them apart, and whether one is inherently better than the other.

Grades, Properties, and Applications of Brass Sheet Metal

Brass is an alloyed metal composed primarily of copper, with a typical zinc content of 5-45% by weight. Yes, that is a wide range, which is one of the primary reasons there so many different grades, applications, and so much history.

Brass is also a ductile and malleable metal, meaning it is easy to shape and form. Many brass alloys are also good conductors of heat and electricity.

Brass is resistant to corrosion, but it is less so than bronze, another copper alloy.

Here at SendCutSend we offer laser cut 260 H02 Brass in five different thicknesses, ranging from 0.04” (1.02mm) up to 0.25” (6.35mm). Grade 260 is a “yellow brass” and has a fetching gold color that’s perfect for decorative projects. Our brass can also be welded, brazed and soldered, and we offer bending, deburring, tumbling and tapping services for most thicknesses.

Brass Alloys & Compositions

There are many different brass alloys, each with its own unique properties based on the ratio of copper to zinc, tin, and other trace alloying elements. Some of the more common types of brass include:

Yellow brass: This is the most common copper/zinc alloy, and gets its name from its color due to relatively high copper content compared to other brass grades at about 65% copper and 35% zinc. It’s technically known as alpha brass, because it contains only one phase, with a face-centered cubic crystal structure. and it is known for its good workability and machinability.

Yellow brass, which is also known as cartridge brass, is used in a huge variety of applications, from musical instruments, electrical connectors, and plumbing fixtures, to shell casings and sculptures

SendCutSend offers 260 series Yellow Brass at a half-hard (H02) temper in five different thicknesses which can be laser cut to meet all your project needs.

Red brass: This type of brass has a higher copper content than yellow brass, and it is known for its high strength and durability. Red brass is commonly used in marine hardware, bearings, and bushings.

White brass: This type of brass has a zinc content higher than 40% and often contains tin or nickel. White brass is known for its high electrical conductivity and corrosion resistance. White brass is commonly used in decorative items such as jewelry or belt buckles, and other applications where its silvery appearance with the toughness of copper are desired.

Naval brass: This type of brass contains about 60% brass, 1% tin, and 39% zinc.It is known for its high strength, durability, and corrosion resistance. Naval brass is commonly used in salt and freshwater marine hardware and other applications where harsh conditions are present.

Lead-Free Brass: In response to environmental and health concerns, lead-free brass alloys have gained prominence. These alloys replace lead with elements like bismuth, silicon, or phosphorus. They are commonly used in plumbing fixtures and potable water systems. Lead “free” brass must contain less than less than 0.2% lead by weight.

Commons Uses for Brass & Brass Sheet Metal

Musical instruments: Perhaps you’ve heard of the brass band? Unsurprisingly, brass is a popular choice for musical instruments because it is easy to work with and produces a good sound. Some common brass instruments include trumpets, saxophones, trombones, and tubas.

Electrical connectors: Due to its electrical conductivity, brass is also a good choice for electrical connectors because, and it’s resistant to corrosion, which would otherwise foul the contact surfaces with non-conductive oxides. Brass electrical connectors are commonly used in a range of industries, including electronics, automotive, and aerospace.

Plumbing fixtures: Brass is a popular choice for plumbing fixtures because it is durable and resistant to corrosion. Brass plumbing fixtures are commonly used in faucets, valves, and, if you’re landed aristocracy, clawfoot soaker tubs.

Hardware: Brass is used in a variety of hardware applications, ranging from door knobs, hinges, and latches to fasteners such as decorative nails and screws. Brass hardware is often chosen for its durability and attractive appearance.

Decorative items: Brass is also used in a variety of decorative items, such as candlesticks, picture frames, and vases. For inspiration on how to use SendCutSend brass to make your next project visually stunning, check out our examples page.

How Brass is Produced

Since the end of the Bronze Age, brass has been produced by melting copper and zinc together. The zinc content of the brass will determine its properties. For example, brass with a higher zinc content will be stronger and harder, but also less ductile and malleable.

Once the copper and zinc have been melted together, the molten brass is cast into ingots or other shapes. The ingots can then be rolled, drawn, or extruded depending on the end use.

What Are The Differences Between Brass and Bronze?

While brass is primarily composed of copper (Cu) and zinc (Zn) it often contains trace quantities of other elements like lead (Pb), aluminum (Al), or tin (Sn), which influence its properties. The proportion of zinc in brass is the primary variable impacting its mechanical and aesthetic characteristics.

Bronze, on the other hand, is primarily composed of copper and tin (Cu-Sn). Like brass, it can also contain trace amounts of other elements such as aluminum (Al), silicon (Si), phosphorus (P), or manganese (Mn) the tin as the primary alloying element is what differentiates bronze from brass.

The compositions, and resultant properties, of brass and bronze tend to mean they’re often used for different purposes: Bronze is favored for its strength, durability, and corrosion resistance, while brass excels in electrical conductivity and is often used in decorative and plumbing applications. The choice between these alloys depends on the specific requirements of the application and the desired properties of the material.

Let’s take a look at a few comparison criteria:

Is Bronze Stronger than Brass?

Brass is generally weaker (has lower tensile strength) and less durable than bronze due to its proportion of zinc vs tin.

Bronze is known for its superior strength and durability compared to brass, making it suitable for heavier-duty applications like large steam valves.

Hardness and Durability Differences Between Brass & Bronze

Brass tends to be softer and its malleability makes it easier to machine or shape, but it may wear out faster in high-friction environments.

Bronze alloys are harder and less malleable, but because they’re more durable and can withstand wear and tear it’s ideal for applications that require wear resistance such as clutch plates and bearings. Oil-impregnated bronze bearings are even used to improve low-friction performance.

Thermal Conductivity

Brass has excellent thermal conductivity, allowing it to quickly dissipate heat. This property is valuable in heat sinks for electronics applications, industrial and scientific heat exchangers and radiators.

Bronze is also a good thermal conductor, although not quite to the extent that brass is. Its ability to dissipate large amounts of heat quickly is helpful in bearing and other friction applications.

Electrical Conductivity

While copper has a higher electrical conductivity than brass, the difference in conductivity is relatively small, and it is typically outweighed by the other advantages of brass. These include lower cost, and higher hardness and durability than copper, meaning that brass connectors can maintain a good contact force even after repeated mating and unmating.

Bronze has fairly good electrical conductivity in comparison to other metals, but because brass and copper are easily available and more effective, it’s rarely used in electrical applications.

Corrosion Resistance

Brass is more susceptible to corrosion in marine and high-moisture environments due to its zinc content.

Bronze is generally more corrosion-resistant, especially in saltwater and marine applications.

Melting Point Differences Between Brass & Bronze

Brass has a lower melting point than bronze, typically between 900°C to 940°C (1652°F to 1724°F) which means that it can be more easily formed without using specialized heating equipment.

Bronze has a higher melting point, usually between 950°C to 1030°C (1742°F to 1886°F) making it slightly more preferable for high-temperature bushing applications where plastic competitors would immediately melt.

Applications

Brass: Commonly used in musical instruments, plumbing fixtures, decorative items, and electrical connectors.

Bronze: Preferred for applications such as statues, bearings, bushings, or marine propellers. It is also found in many very old historical artifacts because it was easier to make than brass using primitive methods.

How to Tell the Difference Between Brass and Bronze

Although they’re closely related, brass and bronze are typically fairly easily identified if you know what to look for:

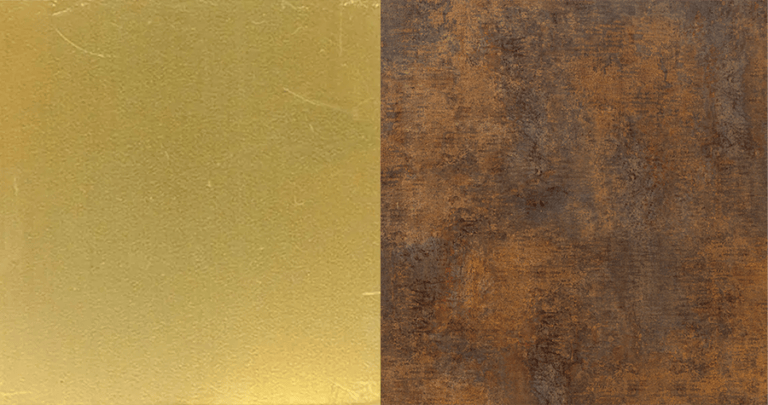

Clean brass has a bright, golden-yellow appearance, making it instantly recognizable. In contrast, even clean bronze exhibits a range of colors, often leaning toward reddish-brown or a darker, earthy hue.

Over time, both brass and bronze develop a patina, which is a natural oxide layer that forms on the surface (think, rust on steel). Brass tends to develop a greenish patina, while bronze takes on a deeper, brownish or greenish hue. Just like when they’re clean the patina on brass is brighter compared to the deeper earth tones found on bronze.

Finally, brass often has a shinier, more reflective surface than bronze, which can have a more subdued or matte finish.

Whereas brass is often polished for a strikingly bright clean look, bronze is often chosen for a more rustic or antique aesthetic.

So, Which Is Better? Brass or Bronze?

This may sound like a cop-out, but after reading this article, you probably know the answer is that it depends:

For example, do you want to be able to polish your project up to a mirror finish? Better use brass. Are you shooting for the ultimate durability and wear resistance? Go for bronze.

For much of the last few thousand years, the terms “brass” and “bronze” referred to the same thing, so you’d be forgiven for not knowing what differentiates one from the other.

| Criteria | Brass | Bronze |

| Composition | Copper and Zinc | Copper and Tin |

| Strength | Lower | Higher |

| Hardness | Softer | Harder |

| Durability | Less durable | More durable |

| Thermal conductivity | Higher | Lower |

| Electrical conductivity | Higher | Lower |

| Corrosion resistance | Lower | Higher |

| Melting point | Lower | Higher |

One thing that shouldn’t be difficult is finding a great material for your next project, and to help you out, we’ve compiled a list of common applications and strengths for each of our materials in our material selection guide. Upload part drawings for instant pricing, fast production, and free shipping on all orders.