Most bike builders start with tubes. Ronin Bicycle Works begins with flat sheet metal and a patented twisting technique that lets them build frames without welding, jigs, or major fabrication equipment. It’s a radically different approach that unlocks lightweight, customized frames that can be built by anyone with basic tools.

For co-founders Andy Davies and Rob Hannum, Ronin Bicycle Works is just one expression of a much larger vision, but bikes were the perfect proving ground.

And from their earliest prototypes to their SEMA-show debut, SendCutSend has been a core part of the journey.

Builder: Ronin Bicycle Works (aka Ronin Metal Masters)

Project: Custom Sheet-Metal Bicycle Frames

Industries: Cycling, Fabrication, Engineering

SendCutSend Services: Laser Cutting, Hardware Insertion, CNC Machining, Anodizing

From Steep Streets in San Francisco to a Sheet Metal Frame

Ronin began with a hill, a brutal 31.5% grade, and a challenge.

Andy was living in a tiny San Francisco apartment at the time, carrying his bike up steps carved into the sidewalk. He needed something lighter. So he set himself the goal of making the lightest functional bike possible.

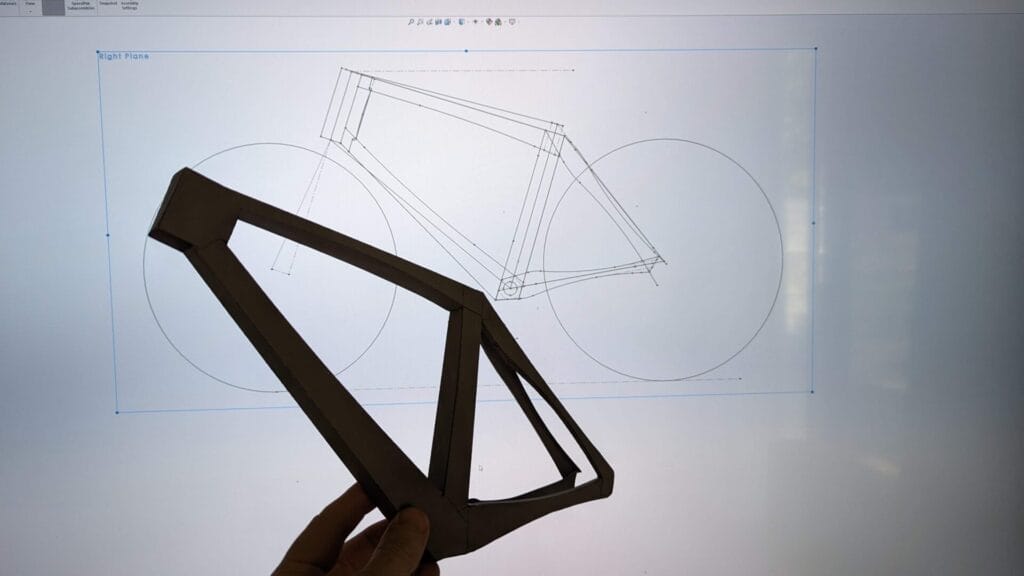

The first prototype was built from 6061-T6 aluminum and held together with only glue and rivets.

“It was like a grown-up version of those 3D metal puzzles,” Andy said.

This first frame proved the technology. “He had built a fully functional, ultra-lightweight bike,” Rob shared. “It became the testing ground for our unique sheet-metal folding technique, while letting Andy work on something he loves.”

A Design Evolution Powered by Laser Cutting

Those early frames were built around older turret punch technology, which meant limited shapes, sharp corners, and lots of compromises.

With modern laser cutting technology, everything changed. In came SendCutSend.

“Designers today are spoiled,” Andy laughed. “Working with SendCutSend is basically cheating. Every edge is intentional now. The latest frame looks a hundred years beyond that first bike.”

Today’s frames are fluid, complex, and precise thanks to laser cut parts and the ability to iterate quickly with no minimum order quantities.

Rob sees sheet metal as the future. “It’s more efficient. Shops only need sheets instead of racks of tubes, angles, and rods.”

A Patented Hand-Bending Technique Unlike Anything Else

Ronin’s core innovation is their patented cross-cut method, a geometrically driven pattern based on years of engineering experience, a deep love of sheet metal, and a bit of structural magic.

“Our technique puts the material into the torsion spectrum of deformation,” Rob describes. “It lets us bend anything with elasticity – spring steel, titanium, even tank armor!”

This means builders anywhere could assemble a Ronin frame. It’s the backbone of Ronin Metal Masters, with applications well beyond bikes, a future they only teased for now.

Rob puts it simply, “There is so much more we have cooking.”

Precision Matters, and That’s Where SendCutSend Shines

Before SendCutSend? Prototyping required “good friendships and bottles of whiskey,” according to Andy. Shops wouldn’t run small quantities, and consistency was a coin toss.

Now? Ronin finally had a partner who could keep up. “You drop in a file and poof, parts in days,” Rob said. “No quote delays. No PDFs. SendCutSend knows exactly what people like us need.”

For Ronin’s frames, every part has to be perfect. Rivet holes have to align across multiple bends. Curved beams need to match precisely across the full geometry. SendCutSend’s laser accuracy, consistent tolerances, and hardware insertion service make that possible.

“I don’t even bother to measure the parts anymore,” Andy said. “Their laser cutting is always ultra-precise.”

And now with CNC machining available, Andy joked, “Honestly, I’m annoyed, in a good way, that they offer CNC now. The possibilities at home are limitless!”

He’s also recently fallen in love with anodizing, and Rob adds, “We have not yet been able to scratch the surface of their capabilities.”

The Power of Accessible Fabrication

When Ronin brought their frame to SEMA with SendCutSend, builders and enthusiasts responded immediately.

One visitor with a pacemaker could no longer weld, but with Ronin’s sheet-metal approach and SendCutSend’s Marketplace, he was now able to continue building bikes.

Another visitor had proportions that made riding commercial bicycles impossible. Ronin is able to adjust a few CAD dimensions and create a custom geometry specifically for her.

These moments stuck with Andy, “I really want to do right by these people, and create a satisfying build experience and a happy, carefree ride.”

A Design Philosophy That Turns Heads

Ronin’s bikes don’t look like anything else on the trail. Riders call them futuristic; they’ve even heard them referred to as “astronaut bikes.”

Andy embraces the comparison. His designs are influenced by origami and the clean, structural lines of sheet metal.

“It’s distinctive, alright. You can’t ride this bike without getting into conversations about it.”

Experimentation as a Core Value

Prototyping at Ronin starts with paper. Andy has built over 20 geometry variations using paper models alone.

“I’ve developed a sense of how strong a metal structure will be based on the strength of a paper model.”

But with SendCutSend making iteration fast and affordable, skipping straight to metal is easier than ever before.

“You don’t learn till you try. Just try. When you fail, you learn,” Rob shared. “Show me an engineer that makes no mistakes and I will show you one that isn’t doing anything.”

What’s Next for Ronin Bicycle Works

Ronin Bicycle Works is just one arm of their broader company, Ronin Metal Masters, which is exploring applications far beyond cycling – reaching into structural frames, furniture, vehicles, and even aviation concepts.

Rob hints at several new bicycle frames he wants to bring to life, as well as a “top secret” project using SendCutSend parts we’re certain promises to showcase what their patented metal-twisting technique can do.

Be sure to visit their website or follow them on social media for the top secret unveiling.

Build Your Vision to Life With SendCutSend

Ronin Bicycle Works proves what happens when innovative engineering meets accessible fabrication. Their partnership with SendCutSend unlocked a new way to build, one that turned origami into rideable machines and empowers builders everywhere to experiment boldly.

If you’re prototyping a new product or trying something the world hasn’t seen yet, SendCutSend has the tools to bring your wild idea to life!

Fill out our Partner With Us form – we’d love to feature your build next.