Have you ever wanted to make a beer keg fly? We admit it wasn’t something we had really thought about, but we know our customers are creative and we’ll support nearly any wild project idea with laser cut parts. That’s why, when we connected with KegRocket, we had to hear their story and what inspired them to use SendCutSend to build a rocket built out of kegs.

At a Glance:

- Industry: Aerospace

- Services: Online Laser Cutting

- Summary: As a propulsion engineer, Ryan Callahan is fascinated by the moonshot projects – the projects no one else is passionate enough to try. He is developing KegRocket as a way to promote STEM through something familiar and fun. But as a personal project, Ryan knew he couldn’t sink more time or money into it than was necessary.

- Solution: The team behind KegRocket turned to SendCutSend to manufacture their parts quickly and efficiently, allowing them to save money while cutting parts to the tight specs needed for aerospace applications.

The Beer Keg That Started It All

In 2021, Ryan Callahan sat at a brewery with some friends after his workday as a propulsion engineer at a space company. It was while discussing rocketry and aerospace topics over a cold beer that Ryan had an interesting thought.

“I was at this brewery and staring at some beer kegs, and it occurred to me that due to their relatively low cost, robustness, and chemically inert stainless steel construction, kegs could make perfect containers for rocket fuel.”

The thought everyone has when they see a beer keg, right? Together with a few friends, Ryan set plans in motion to launch to where no keg has gone before.

It’s Just Rocket Science, After All

The KegRocket project came at a perfect time for Ryan. He was looking for a new project to take on outside of work. He missed the camaraderie and fun of working on projects with a group of friends, and he sought something unique and lighthearted to share with the greater STEM (science, technology, engineering, and math) education community. KegRocket was the perfect solution.

The team behind KegRocket is mostly made up of San Diego State University alumni who were part of the rocketry team on campus, as well as a few other individuals who were involved in rocketry teams at other universities. The team is working hard to get KegRocket off the ground and their shared background helps them attack all the hurdles that come with such a unique project.

The team decided to use a keg in their project for ultimately one reason: to make rocketry more accessible. It is an easy project to get excited about because it takes something familiar and simple (beer kegs) and marries it with complex topics that are traditionally out of reach for us non-rocket scientists.

“I think the juxtaposition between beer and “hardcore rocket science” is comedy gold for any appreciator of beer and/or aerospace, which makes this rocket a perfect culmination of epic-ness that almost anyone can get excited about.”

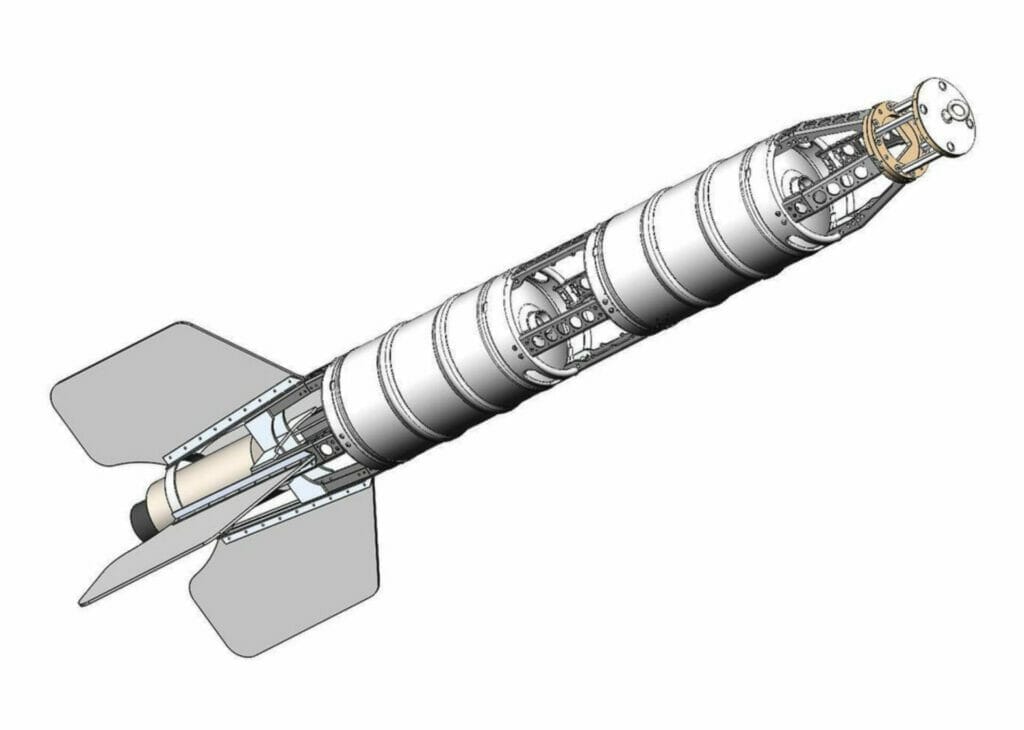

Beyond making the inaccessible accessible, the kegs actually function as an integral part of the rocket itself. Most standard amateur rockets are what’s known as solid-fuel rockets: they burn a preloaded chunk of fuel which produces the thrust needed to fly. Solid-fuel rockets are typically simpler to execute at an amateur rocketry level. However, the chemically inert stainless steel beer kegs are used as tanks for liquid fuel and oxidizer, which classifies KegRocket as a liquid bi-propellant rocket. Liquid-fuel rockets burn a liquid oxidizer and a liquid fuel together to produce thrust, which can be a much more complex and difficult undertaking for a homebrew project.

As someone who follows many amateur rocketry projects, Ryan knew that several people had launched things like beer cans or full beer kegs in the past just for fun. But no one had taken the keg and made it a core part of the propulsion system as a fuel tank in and of itself. With the recent resurgence of amateur rocketry, KegRocket strikes gold as being both functional and fun.

“Amateur rocketry is in a bit of a renaissance, and from the outside in, it can seem inaccessible and difficult. So we’re taking this absurd, non-technical thing and turning it into a functioning rocket fuel tank. We want people to know that you can get into this hobby at any level and grow with it, no previous experience required.”

Designing KegRocket With Manufacturing In Mind

In addition to rocketry, Ryan is also an automotive enthusiast. He was building a project car when a group of people at work introduced him to SendCutSend.

“The online tools were so easy to use, especially since I just needed a special bracket and didn’t want to deal with overpriced fabrication shops. It was all a slam dunk for my car project, and I wanted to find other ways to use the services in my projects.”

As the ideas for KegRocket formed in his mind, Ryan knew this would be the perfect application of our online laser cutting services. Not wanting to deal with large suppliers who don’t want to work with small businesses and hobbyists, the team designed KegRocket from the very beginning around the services we offer at SendCutSend. The materials, machining methods, and tolerances were all chosen with SendCutSend manufacturing in mind.

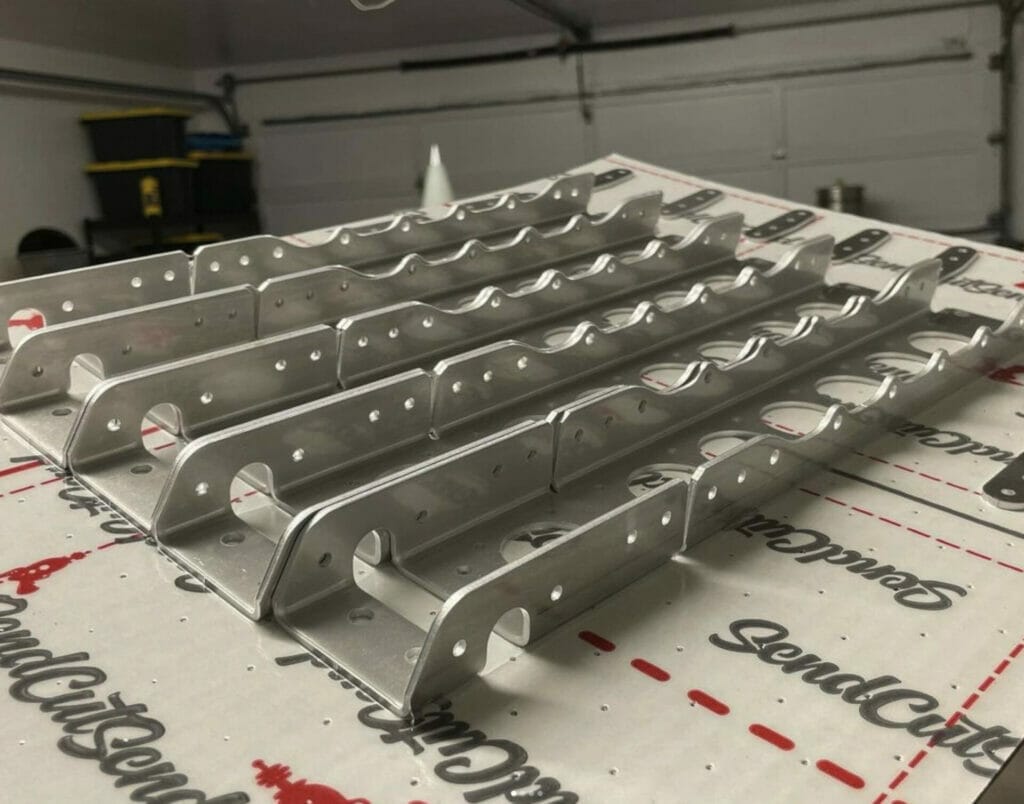

KegRocket currently utilizes our laser cut 5052 aluminum as well as our CNC bending services. They chose 5052 aluminum because it’s easily formed, light, and inexpensive. KegRocket also features a few stainless steel parts laser cut by us. Ryan also hopes to use our powder coating or anodizing services for future KegRocket parts. The rocket is designed to look cool and be appealing to all, and the team knows how much a service like anodizing can elevate even the simplest of parts. We’re looking forward to seeing how the aesthetics of the project turn out!

Manufacturing parts for aerospace applications, even hobby ones, is difficult, time consuming, and costly. Using online laser cutting services helped cut down on all of those issues for KegRocket, making the project more attainable and allowing the team to focus on the real rocket science.

“This is a passion project, which means there is always a potential for way more time and money sunk into it than initially expected. It’s a big deal for us to fit everything within a reasonable budget and find parts that are well-produced and cost effective. We really appreciate SendCutSend’s quick process and affordability because it has made this project possible.”

What’s Next for KegRocket

Ryan hopes this project will inspire others to pursue the passion projects they’ve put off for years. And he knows firsthand how helpful our SendCutSend services can be, so he encourages other hobbyists and small business owners to explore the variety of laser cutting educational resources available on our site to help them get started.

“The world is your oyster thanks to the resources available on SendCutSend’s website. Read the design guides and adhere to them, and your parts will come out perfectly every time. And their customer support agents are the nicest people so if you still have questions after reading through their articles, they’ll help you find the right answer!”

KegRocket is a huge multi-year project. So far the team has finished the airframe and structure, and have moved on to the fluid systems and they’re targeting a Spring of 2024 launch date. Although the team will be excited just to see KegRocket get off the ground, their current simulations suggest KegRocket could fly as high as 18,000 feet!

KegRocket’s ultimate goal is to encourage more people to explore amateur rocketry and aerospace. With thousands of people already eagerly following the team’s progress, they are well on their way to achieving that goal.

Make sure to keep up with Ryan and the KegRocket team by following their Twitter and Instagram and keeping an eye on their website!

Bring Your Passion Project To Life With Online Laser Cutting

No project is too wild for our services. Whether you’re looking for online laser and waterjet cutting or aesthetic finishing like anodizing or powder coating, we can help you make your dream projects reality. Don’t hesitate to reach out to our support team with any questions you may have!

–

Do you already use parts from SendCutSend in your products? Reach out through our Partner With Us form to tell us all about it. We’ll be in touch!