HDPE (High Density Polyethylene) is one of the most commonly used plastics in the world. In this article we deep dive into what it is, where it’s best used and even where to avoid using it.

What is HDPE?

HDPE stands for High Density Polyethylene. The density (or molecular weight) is used to differentiate it from other polyethylene materials such as LDPE (Low Density), MDPE (Medium Density) and even UHMW (Ultra High Molecular Weight). We won’t go into the details of manufacturing processes to produce the differences between these, just know that they have a lot in common with enough differences in weight, strength, etc. to be useful in their own unique applications.

HDPE is a thermoplastic polymer. Thermoplastic meaning heat can be used to soften and form the material. Once cooled, it retains its original properties. This process can be repeated multiple times with little to no changes in the materials properties. Polymer just means the material is made up of long repeating chains of molecules.

HDPE Appearance Overview

“Natural” HDPE is usually milky white, slightly translucent. HDPE can also be colored, but natural is the most common. The surface texture of HDPE depends on how it’s formed; it can be smooth or textured. The High Density Polyethylene you get from SendCutSend is available in white or black, and has a textured surface on both sides.

6 Benefits of High Density Polyethylene

- Recyclable

HDPE is one of the most recyclable plastics. It’s category number 2 in the recyclable plastics chart. A lot of consumer products made of plastics have a symbol molded into them to help identify what type of plastic they’re made from. A 2 identifies HDPE.

- Strength

The higher density of HDPE compared to LDPE/MDPE makes it heavier, but it also makes it stronger and more rigid. HDPE typically has a higher strength-to-weight ratio than LDPE, so while it is heavier, it more than makes up for the extra weight in strength.

- Formability

Like most thermoplastics, HDPE can be softened with heat and formed into unique shapes. You can find HDPE in sheet form, but also injection molded, blow molded and even rotational molded forms. Two of the most common forms you can purchase HDPE are sheet and pellets for molding.

- Chemical Resistance

HDPE is resistant to a wide range of chemicals. Because of this, HDPE is a popular choice for fluid containers. Milk jugs, shampoo bottles, even fuel containers are made from HDPE. It also makes it resistant to many forms of rot, mold and mildew.

- Low Moisture Absorption

HDPE is frequently used in marine applications because of its low moisture absorption. There are types of HDPE that are sold under the name Marine Board, specifically for boating applications.

- Impact Resistance

One of the most utilized properties of HDPE is its impact resistance. HDPE is a very durable material, able to take heavy impacts without breaking.

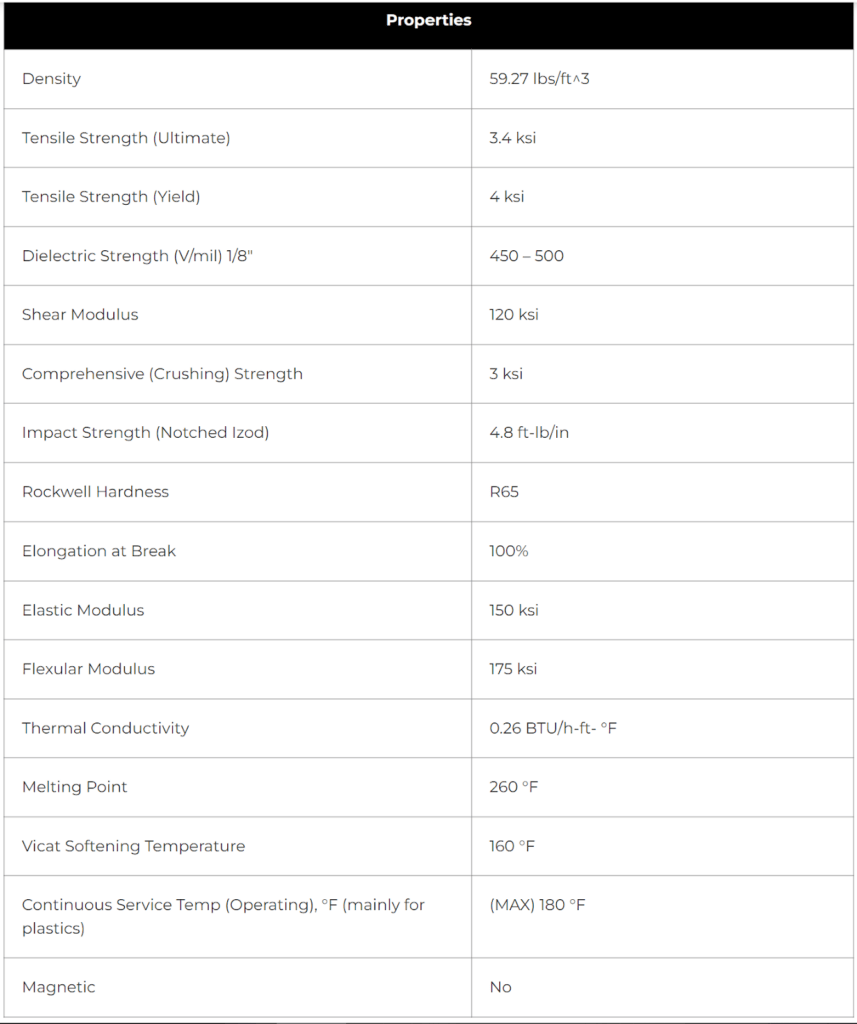

HDPE Properties

There are different types of HDPE with varying properties depending on the raw materials and processes used to manufacture it. The specific properties of the HDPE you get from SendCutSend can be found on our materials page. For convenience we’ve summarized the properties here.

How to Best Cut HDPE

We use our CNC router to cut HDPE. It cuts very clean and smooth. In fact, you can easily cut HDPE with woodworking tools. A handheld router with a pattern bit (a bit with a guide bearing to follow a pattern) can make cutting repeatable shapes from High Density Polyethylene a breeze.

Downsides of HDPE

While HDPE is a commonly recycled plastic, it is still plastic, which means it isn’t biodegradable. That’s good for applications where you need a part to survive the elements and not break down, but not so good for parts that don’t get recycled.

Because of its excellent chemical resistance, gluing HDPE can be difficult. There are special adhesives and epoxies made for plastics like HDPE, but if you want a strong joint, plastic welding is a better option. You can also use fasteners to hold HDPE parts together. In fact, countersinking and tapping threads are both services SendCutSend offers for HDPE.

HDPE isn’t as strong or hard as UHMW, and it isn’t as light or soft as LDPE. Depending on your project, one of those may be a better choice. If you need a stronger material, SendCutSend carries both HDPE and UHMW.

Applications and Uses of High Density Polyethylene

HDPE is one of the most common plastics used today. You probably come across it multiple times every day.

- Bottles – Milk jugs, shampoo bottles, laundry detergent containers are typically made from HDPE because of its resistance to chemicals. Water bottles can be made from HDPE, but are often made from a different plastic called PET.

- Storage Containers/Bins – Plastic bins of all sorts get made from HDPE due to its strength, low cost and ability to be injection molded into nearly any shape.

- Cutting Boards – Plastic cutting boards are usually made from HDPE. It can hold up to kitchen knives well and is resistant to bacteria.

- Toys – Toys can be made from all sorts of plastics, but again HDPE is widely used for its low cost and ease of manufacture.

- Pipes – Used to transfer a range of fluids and gases, HDPE pipes are flexible, resistant to chemicals and corrosion.

- Plastic Lumber – HDPE is used in place of wood in many areas because it shares a lot of positive traits with wood, but doesn’t rot like wood. It resists moisture, mold and mildew.

- Marine Fittings and Bulkheads – Because it doesn’t absorb moisture and isn’t damaged by salt water, HDPE is a great material in marine environments.

HDPE vs UHMW

We’ve already discussed how UHMW is the stronger, denser big brother to HDPE. Because of that difference, UHMW tends to be used in heavier duty applications such as bushings, bumpers, machine guides, wheels, etc. UHMW has better wear resistance, impact resistance and strength in general.

Find the Best Plastic for Your Project at SendCutSend

SendCutSend doesn’t just carry High Density Polyethylene, we also carry the tougher UHMW, but if neither of those are right for your project, take a look at ABS, Delrin, Acrylic and Polycarbonate. Each with their own unique strengths and limitations. If you can’t decide which plastic to choose, we’ve got some great resources to help you out. Check out our materials pages for detailed specs, our services page to see which of our services (way more than just cutting!) you can take advantage of, and visit our blog for articles just like this one on all kinds of topics.