Imagine Amazon Prime with two big differences. First, you have to know your way around CAD or a design program to order. And second, when your package arrives faster than you expected, you open it to find something completely custom that you created yourself.

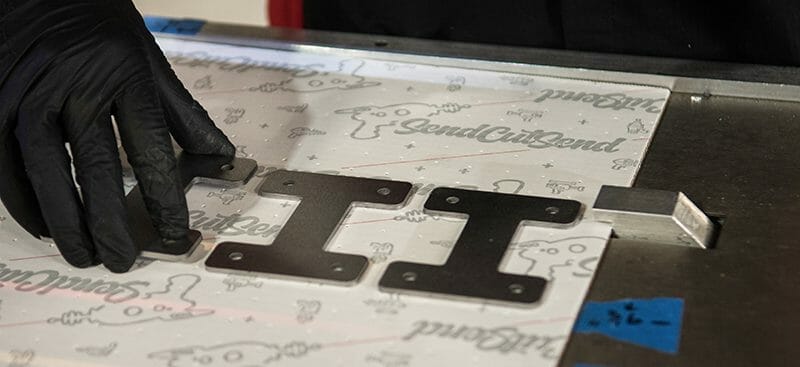

That, in essence, is SendCutSend. Created for creators. Powered by personalization. All cut and shipped as fast as humanly (and robotically) possible.

Personalization is a huge trend among makers and hobbyists. That passion for unique craftsmanship, hand-designed solutions and customization has fueled us at SendCutSend. They are beautiful gifts, highly sought-after artisan crafts, wild creations that can’t be re-created, or ingenious solutions to difficult problems.

Mass customization vs. true customization

Not long ago huge brands launched into what today is termed “mass customization.” It was customization with a catch. The building blocks of the main product were the same, but customers were free to customize the finishes with a limited array of customizations. Think a car with a unique airfoil, or a different seat material, or even a unique fender design.

Deloitte in their annual consumer report Made-to-Order: The Rise of Mass Personalisation noted the trend:

Empowered by social networks and their digital devices, consumers are increasingly dictating what they want. They have become both critics and creators, demanding a more personalized service, and expecting to be given the opportunity to shape the products and services they consume … Moreover, not only would the majority of customers be willing to pay more for a customized product or service, they would also like to be involved in the process.

Personalization has been popping up everywhere. Shoe companies offer different laces, material, even soles as large shoemakers respond to the demand for something unique and personal. But much of this personalization was still reserved for big brands with big budgets. And it was often the illusion of customization. Modular, plug-and-play components of shoes, fashion and automobiles allowed large brands to plug in new design features while still mass producing the main components.

Then, companies like SendCutSend came along. With a commitment to the highest quality prototyping and laser cutting equipment and software that speeds up ordering and delivery, this new breed of business offers high-quality customization to creators and empowering personalizers.

All that is left is to dream, design and have it delivered to your doorstep.

Expectations of Personalization

It should be noted that personalization is now expected. Our apps know our preferences. Our social media platforms feed us things we’re interested in. Our online retailers suggest products they already know we’ll love.

Against this backdrop, personalization is going mainstream. Deloitte found that 36 percent of all consumers expressed interest in purchasing personalized products or services, but in some categories, that interest rose to over 50 percent.

Companies like digitally powered custom tailors can now deliver the benefits of a custom-fitted suit quickly at scale. Flower makers can deliver customized bouquets and drink makers offer custom-designed bottles and packaging.

For the oddballs among us, you can even upload a photo of yourself to Potato Parcel and have a potato with your face printed onto it hand-delivered to a friend or family member. Personalized Potatoes. Who would have thought?

Makers are riding this personalization wave with an even deeper dedication to the whims of the consumer. Like cloud computing and the ubiquity of digital technology fueled a new crop of digital entrepreneurs, online laser cutting services like SendCutSend are giving rise to a new breed of maker and craftsperson, dedicated to the custom experience customers crave.

So, what can you create with customization?

Here are a few things we’ve seen come through our laser cutting factory floor:

- A 3-D steel deer head, welded together from interlocking laser cut panels.

- A skateboard truck that doubles as a bottle opener.

- “Brass” knuckles that are actually made from laser cut titanium, which also happens to open bottles.

- A laser cut aluminum laptop stand.

- A hand-powered mechanical butterfly metal sculpture.