Home » Services » Online Waterjet Cutting » Texas » Dallas

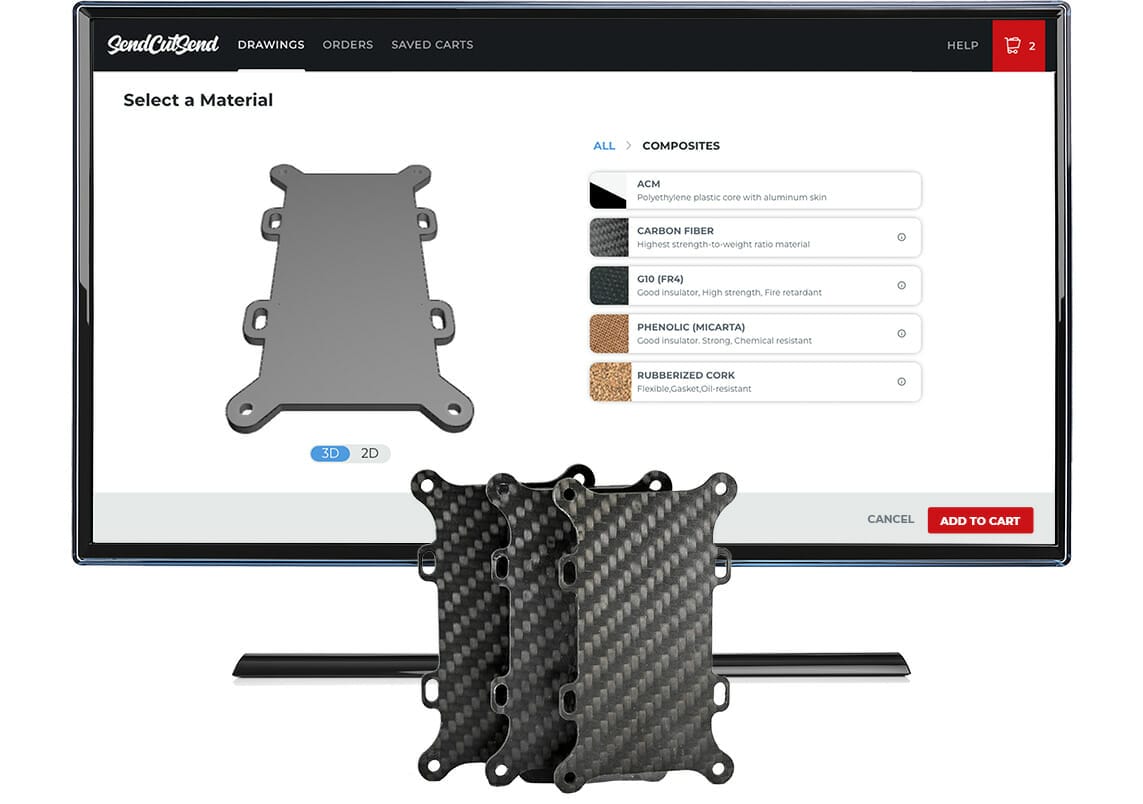

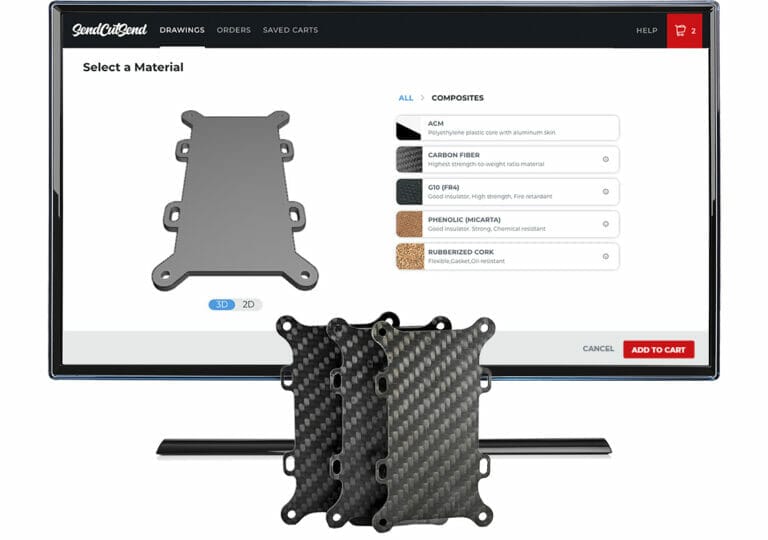

For the precision cutting of composite materials like carbon fiber, G10/FR4, Phenolic (Micarta), and more, our customizable and automated system utilizes waterjet technology, which eliminates delamination, rough edges, and HAZ issues that can arise during laser cutting. At SendCutSend, when you upload your design we pick the best cutting process based on your material and project needs.

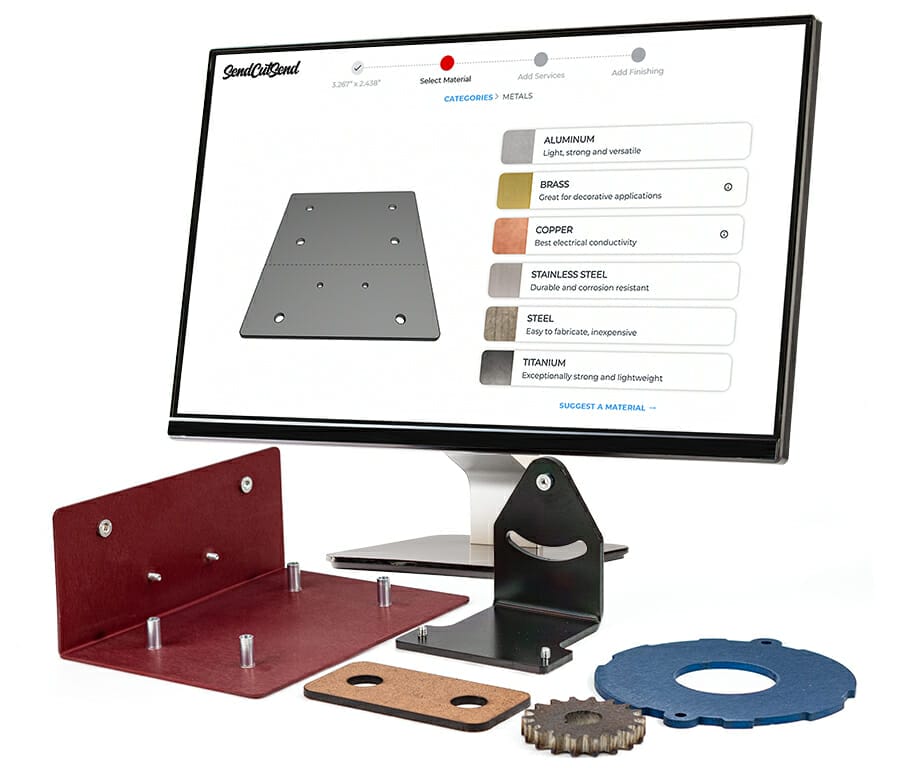

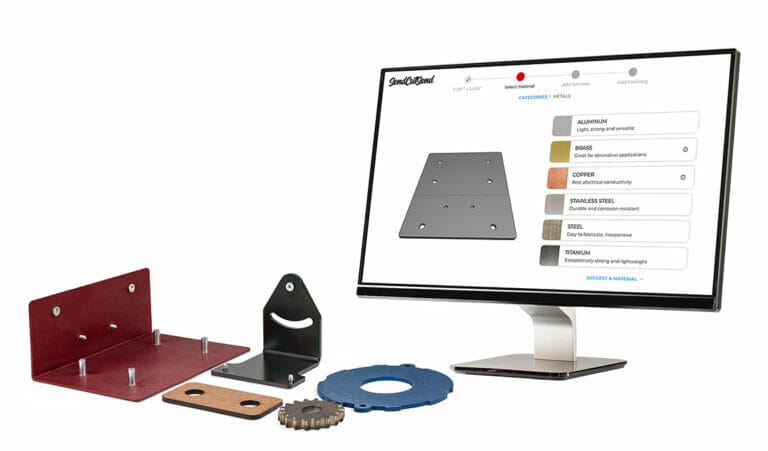

SendCutSend uses the best cutting method for your parts, including high power fiber lasers for metals (from 4kW to 12kW+), CO2 lasers for plastics, CNC routers for wood, and CNC waterjets for composites such as carbon fiber.

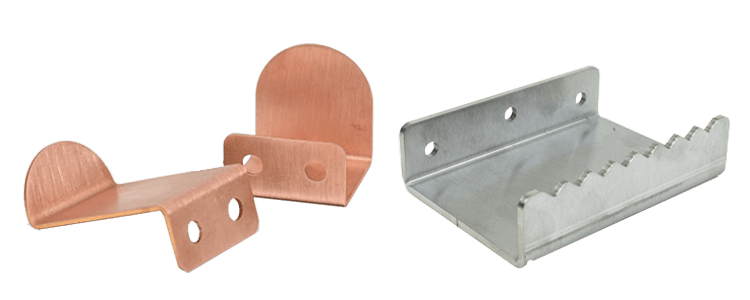

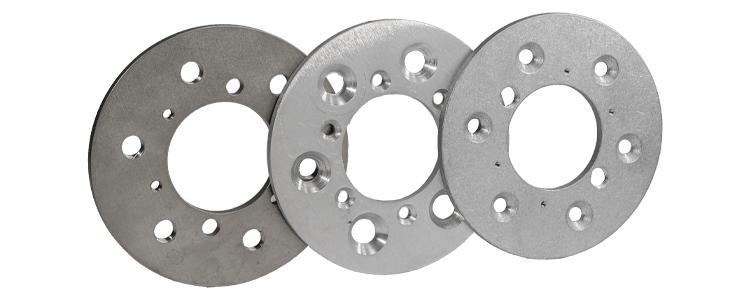

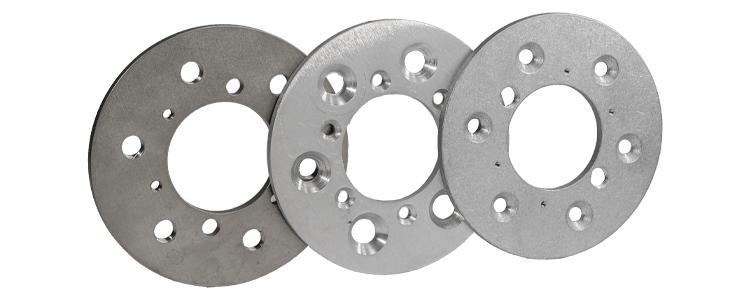

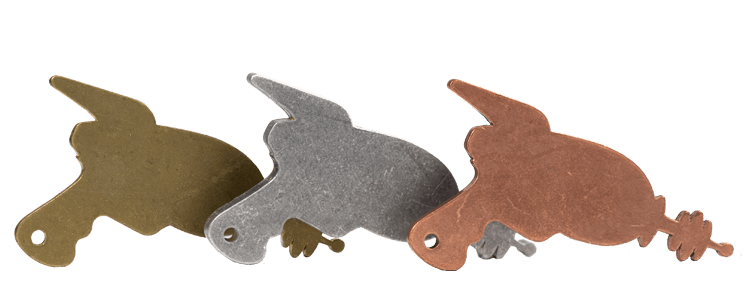

We’re able to make incredibly accurate cuts with tolerances of +/- .005″ or better on aluminum, steel, copper, stainless steel, brass, acrylic, carbon fiber, wood and more (over 165 materials in stock).

Waterjet is capable of highly intricate cuts with tolerances of +-.009” (.25mm) or better in composite materials.

Expect tolerances of +-.009” (.25mm) or better in composite materials.

The combination of water speed, pressure, nozzle size and abrasive flow rate allow waterjet cutting to produce a superior edge quality compared to laser cutting.

When your parts are waterjet cut there’s virtually no HAZ (heat-affected zone).

The combination of water speed, pressure, nozzle size and abrasive flow rate allow waterjet cutting to produce a superior edge quality compared to laser cutting.

The crushed garnet in the waterjet stream acts like a belt sander, slowly abrading away the material, leaving a very smooth edge. Dross and burr commonly found in other cutting methods is effectively eliminated.

When your parts are waterjet cut there’s virtually no HAZ (heat-affected zone).

The crushed garnet in the waterjet stream acts like a belt sander, slowly abrading away the material, leaving a very smooth edge.

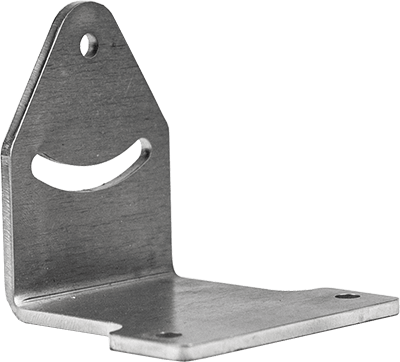

Custom laser cutting, waterjet cutting, and CNC routing. We’ll cut your parts with the method best suited for your sheet or plate material.

2-4 days standard production

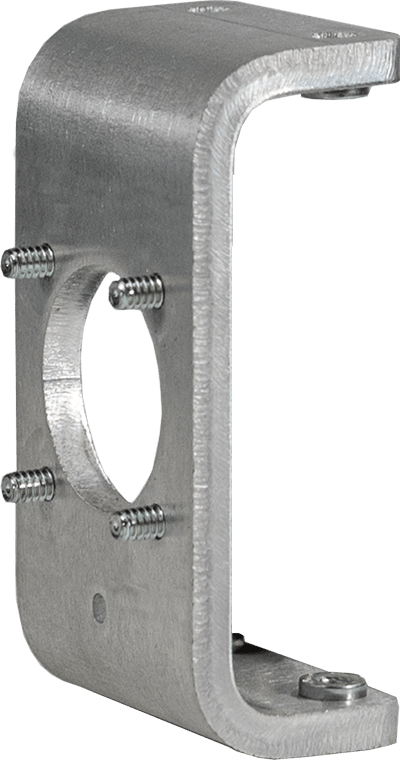

Our fast laser tube cutting services deliver precisely manufactured parts in round, square, and rectangular tube metal materials.

2-4 days standard production

Multiaxis CNC machining in billet stock. This subtractive process uses precise machining to sculpt blocks of raw metal into nearly anything you can imagine.

2-4 days standard production

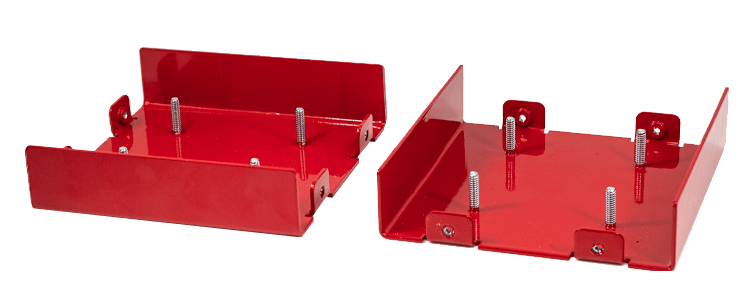

Add dimension to your projects with our precision CNC bending services.

+1-2 days | 10 materials

Allow hardware to sit flush on your parts to reduce wear and tear.

+1-3 days | 6 materials

Strengthen material with aesthetically pleasing dimples.

+1-3 days | 7 materials

Easily add text and small details to your custom cut parts with our metal laser engraving services.

+1-3 days | 3 materials

Select from our catalog of PEM press-fit hardware to add nuts, studs, and standoffs.

+1-3 days | 8 materials

Quickly and easily add threading to allow for the addition of hardware to your parts.

+1-3 days | 12 materials

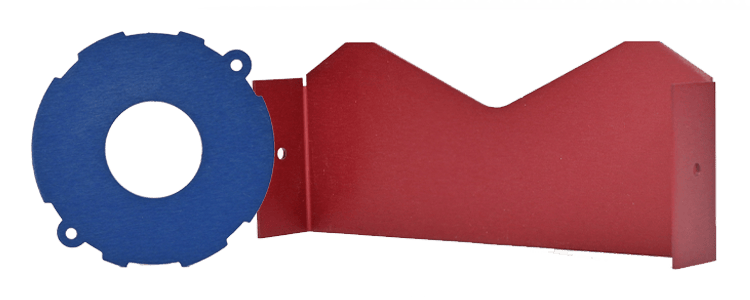

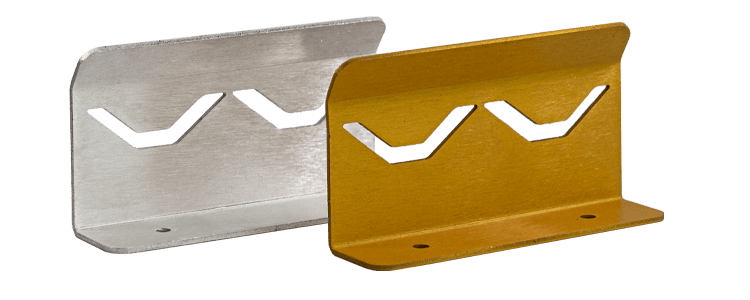

We offer Class II anodizing services to add durability and character to your laser cut parts.

+7-10 days | 3 materials

This process removes small imperfections, scratches, and burr left over from the cutting process.

+0 days | 8 materials

Increase rust prevention, wear resistance, and strength with zinc and nickel plating.

+7-10 days | 3 materials

Give your laser cut parts a bold, long-lasting finish and protective layer in one of 7 colors, 4 finishes

+7-10 days | 9 materials

Reduce the surface blemishes and handling scratches found in raw materials.

+1-2 days | 11 materials

Pricing is based on the selected material, material thickness, part size, and design density. Upload your file to get instant pricing.

When you upload your file to SendCutSend we determine whether to use our fiber lasers, CNC routers, or waterjets to cut your parts. We currently cut the following materials on the waterjet, but have more than 165 materials in stock including metals, composites, plastics and wood.

Our educated and friendly team is here to answer your questions and assist you in getting the best parts possible.

We make everything right here in the US at our facilities in Reno, Nevada and Paris, Kentucky. From cutting to bending to powder coating, to software engineering and customer support, your parts are truly made in the USA.

All our services come guaranteed. If you’re not 100% happy with your parts, we’ll give you a refund or remake on the spot.

We know your designs are valuable. Your files are 100% secure in our system.

If you don’t have a DXF file for laser cutting, no problem! Our Parts Builder features fully customizable laser cutting templates, which allow you to select, customize, and order a variety of parts from simple brackets to house numbers in a matter of minutes.

Have a detailed sketch or a cardboard template? Send it to our Design Services team. We can create a CAD file to add to your cart.