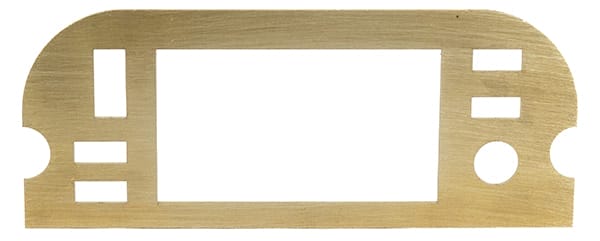

Our 260 series H02 laser cut brass can be soldered, brazed, and welded and is highly formable. Brass is commonly used for bushings, busplates and busbars, and ornamental designs.

A: .25″ x .375″

B: 30″ x 44″

.040″ (1.02mm)

.063″ (1.60mm)

.125″ (3.18mm)

.187″ (4.75mm)

.250″ (6.35mm)

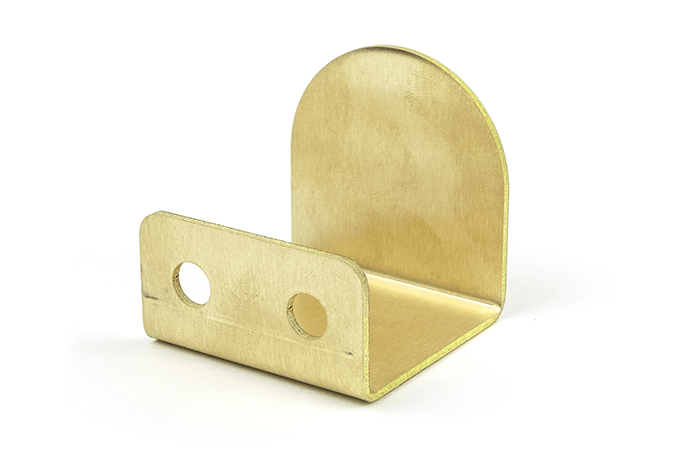

Our laser cut brass is gorgeous, easy to form, bend, and machine. This makes it the perfect material for your smaller hinges, locks, and other fasteners well-suited to brass usage.

Brass prevents bacterial growth due to its innate antimicrobial properties. It’s great for applications that are exposed to handling, such as bathroom fixtures.

Additionally, unlike steel and iron, brass will not rust when used in external applications, and that makes it great for signage and decorative displays. However, if you intend to use it this way, it’s important to note that it will corrode with moisture, specifically in the form of tarnish.

Brass is a combination of copper and zinc (with a few other trace elements), and the tarnishing effect is similar to copper.

SendCutSend’s brass cutting service will provide beautiful parts made to your specifications.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers Brass in five thickness options: .040″ (1.02mm), .063″ (1.60mm), .125″ (3.18mm), .187″(4.75mm), .250″ (6.35mm).

When ordering Brass through SendCutSend, there are specific size and thickness parameters to keep in mind. For instant quoting, the smallest part size available is .25″ x .375″, while the largest part supported is 30″ x 44″.

You can add the following services to your Brass parts:

Bending, Deburring, Tapping, and Tumbling