Last November, we introduced the bold collaboration between Mike Burroughs of StanceWorks and SendCutSend, as Mike took on the ambitious task of building a Ferrari F40 from the ground up. Now, the project is starting to take shape, with the tube chassis coming together, a legendary Ferrari V12 in the shop, and the SendCutSend fixture table taking center stage.

But what makes this update especially exciting is how Mike has continued to push the limits of what’s possible with laser-cutting, not just by fabricating end-use parts, but by creating entirely custom tools and jigs using SendCutSend’s services.

We caught up with Mike for a progress check, and he gave us a deep dive into how digital design and fabrication are powering one of the most anticipated custom builds in the automotive world.

Company: StanceWorks

Product: Automotive Fabrication & Restoration

Industries: Automotive

SendCutSend Services: Laser Cutting, Custom Brackets & Parts

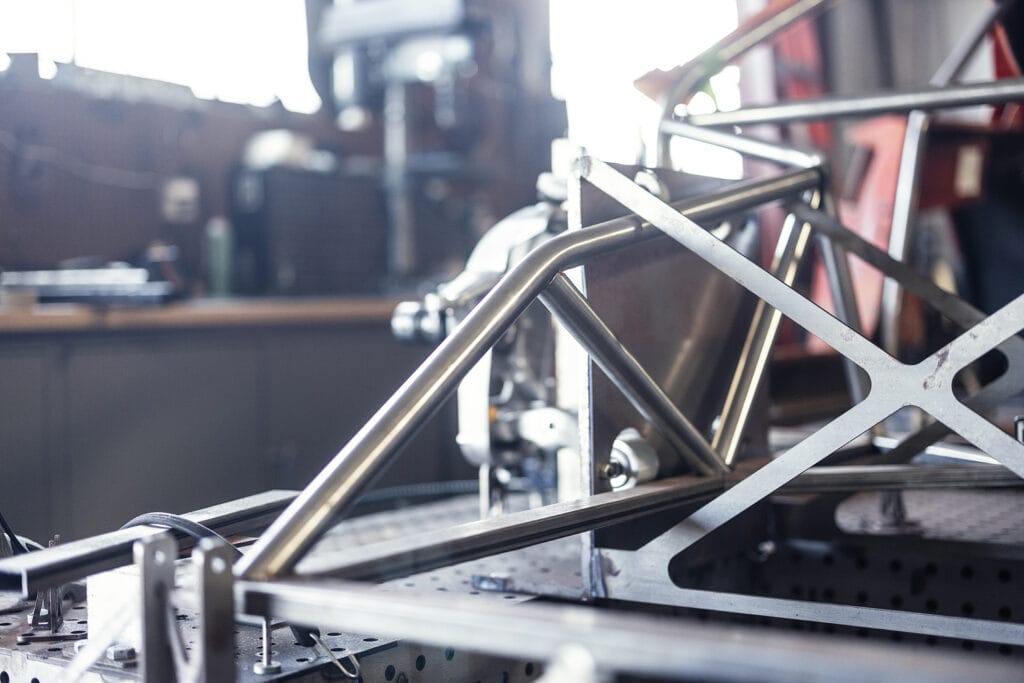

Laser-Cut Fixture Table Brings A Chassis to Life

While the 2024 racing season pulled Mike away from the shop more than expected, the F40 Evo project has reached a significant turning point.

“The front end is mostly mocked up and designed. It’s starting to look like a car in the front half!” exclaimed Mike.

With the initial CAD work complete and the SendCutSend fixture table dialed in, Mike is now cutting and bending tube to begin finalizing the chassis structure, arguably the most foundational phase of the entire project.

The table has been key to building every major substructure. “It really allows me to make sure the car is straight, plumb, and level. In its simplest terms, it serves as a “home base” or a “true zero”, explained Mike.

Supporting modular jigs, mounts, and brackets, Mike can bolt everything into place as the design evolves. Having built cars on his shop floor in the past, he expressed that the table has been an absolute game-changer for him.

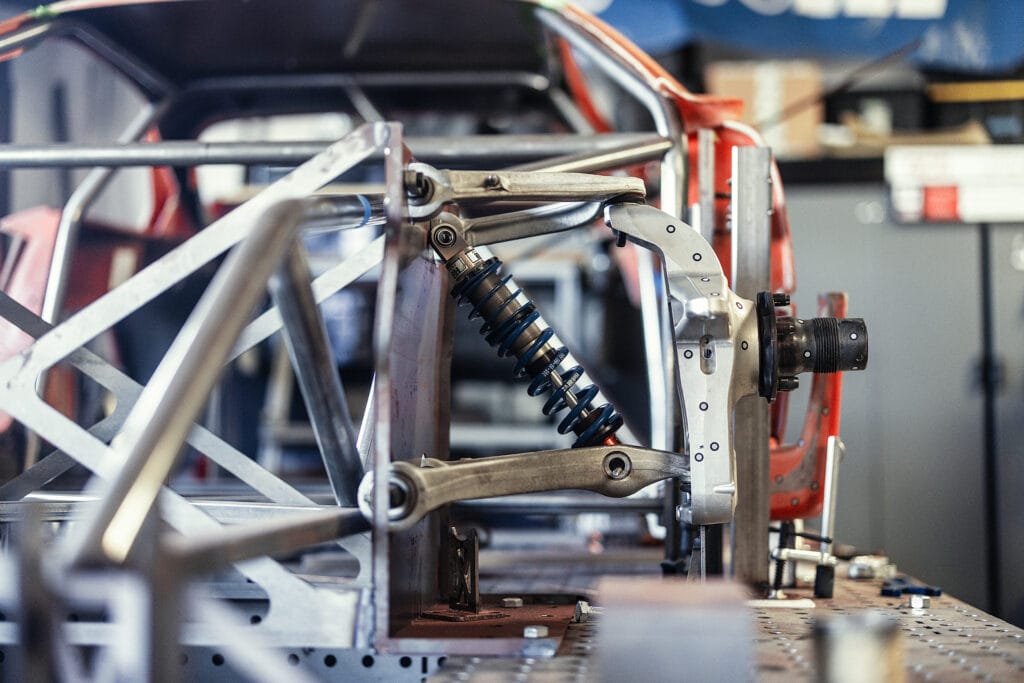

Custom Suspension with a Factory Ferrari Twist

When it comes to performance, Mike didn’t want to only ‘come close’ to getting it right. He wants the car to handle at an unparalleled level, so he turned to Ferrari for inspiration.

“I figured I should copy Ferrari’s homework and just transplant their race car suspension from the last decade onto my car.”

Mike has designed his own suspension for past projects, but he opted to source all the running gear from a Ferrari 458 Challenge Evo and use 3D scanning to map out the pickup points for this build. With that data, he used SendCutSend to laser-cut mockup jigs that allowed him to position the suspension geometry precisely on his own chassis.

As the build progresses, he’ll once again rely on SendCutSend to fabricate all the steel suspension mounts for the tube frame.

Innovating Precision Tools with SendCutSend

One of the most innovative parts of Mike’s approach is using laser-cutting not just for components but also to create the tools and jigs that make those end-use parts possible.

“Humorously, a lot of YouTube commenters have said the project has been just as much about building tools and jigs as it has been about the car itself,” Mike laughed. “But if there’s a tool I can make to help with the build, I go for it.”

These include everything from alignment fixtures to hold body panels in place to engine stands that support the massive Ferrari V12 during pre-installation testing.

“I know hearing the V12 sing will get a lot of people excited. So, I spent far too long designing an engine stand, and turned to SendCutSend to build it.”

A Mindset for Builders

Mike’s biggest advice to builders? Don’t be afraid to fail. Learn by doing, and don’t assume you need a formal background to build something ambitious. Oh, and save your CAD files…often.

“I’m just a hobbyist in the garage with no classical training. If you see me do something, you can do it too,” he shared.

That mindset, that failure is the first step towards improvement, combined with modern fabrication tools, is changing what’s possible for solo builders.

“SendCutSend has transformed my capabilities into something far beyond what I could have imagined. It’s the most powerful tool in my toolbox,” you’ll hear him say often on his channel.

He’s especially excited to begin experimenting with SendCutSend’s new CNC machining services once the current race season wraps up.

Building Momentum

As the F40 EVO inches forward, the next few months will focus on finalizing the chassis, fitting the suspension components, and beginning work on dressing the engine for its first fire.

“Momentum is finally picking up. I’m excited to get lost in the shop.”

Mike’s approach is iterative and flexible but grounded in solid design work and smart tool usage. 3D scanning has allowed him to reverse-engineer many parts on the project, from bodywork to suspension and even the engine. And he’s not putting the 3D scanner down anytime soon.

And yes, at some point, that glorious V12 will be fired up. If you follow StanceWorks on YouTube, you won’t want to miss it.

More Than Just Laser-Cut Parts

Mike’s evolving F40 project is more than a wild reimagining of a Ferrari icon. It’s a blueprint for how digital tools, custom fabrication, and the right mindset can bring even the most ambitious automotive dreams to life.

“It’s still just a car, and cars are meant to be driven,” Mike says. “I’d be disappointed to put so much time, effort, and money into a project and not use it to its fullest extent.”

We’ll continue checking in as Mike brings one of the most iconic silhouettes in automotive history to life, with a few wild twists of his own.

Bring Your Project to Life

Inspired by Mike’s build? We want to see what you’re working on. Fill out our Partner With Us form and share your project.

Looking for parts, jigs, or custom tools of your own? Let’s build something together! Explore our online Marketplace and services. With a quick turnaround and over 185+ materials, your imagination is the only limit.