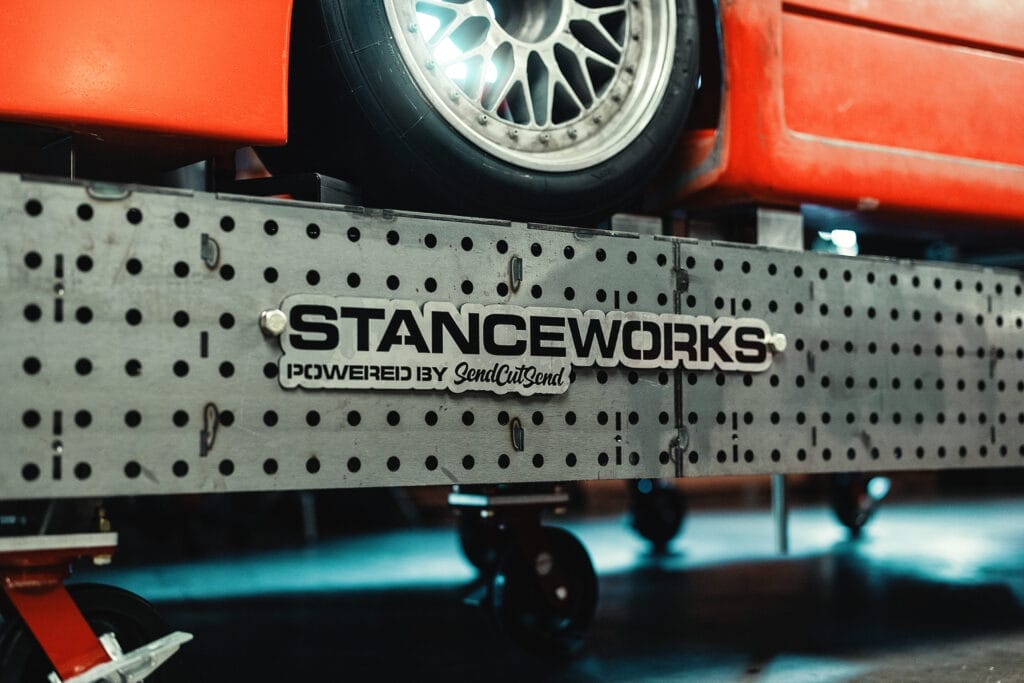

StanceWorks has been pushing the boundaries of stance and wheel fitment since 2009. Now, 15 years later, owner and Editor-in-Chief Mike Burroughs, is taking on his biggest challenge yet – reimagining the iconic Ferrari F40 into what he only hopes will be its craziest race car form. When SendCutSend heard what Mike was up to, they knew they wanted to be a part of his build.

“Something I’m really looking forward to is seeing the ways in which I can utilize technology like SendCutSend to make this car the best I’ve done so far,” shared Mike.

Mike is looking forward to flexing his CAD design muscles and really diving into the details to bring these designs to life in not only aluminum or steel, but carbon fiber and other mediums. His plan? Make a car that’s not anything like he’s ever done before.

Company: StanceWorks

Product: Automotive Fabrication & Restoration

Industries: Automotive

SendCutSend Services: Custom Brackets & Parts

The Classic F40 with a Twist

Whether you’re in the car scene and have followed Mike’s outrageous builds over the last few years, or you simply hop into your sedan to get to and from work, we bet you’ve heard of Ferrari. What you might be less familiar with, is the classic F40, the fastest production car in the world at its time. While this car might not be the rarest sports car out there, it comes with one hefty price tag – some going for $3.5 million.

By a stroke of luck, StanceWorks got their hands on a set of original, authentic body panels (for well under that price tag), and Mike knew he could build the car to go underneath them.

“The real deal is clearly not something I’d ever be able to afford,” shared Mike. “This felt like the perfect opportunity to have the ‘real thing’ in an even better way, that suits me – the body is all I’d want from the real car anyways”.

StanceWorks is setting out to make something special and visually stunning, paying homage to Ferrari while doing something that hasn’t been done before. “We aren’t building a replica, so those constraints go out the window,” said Mike.

Bringing A Blank Canvas to Life with SendCutSend

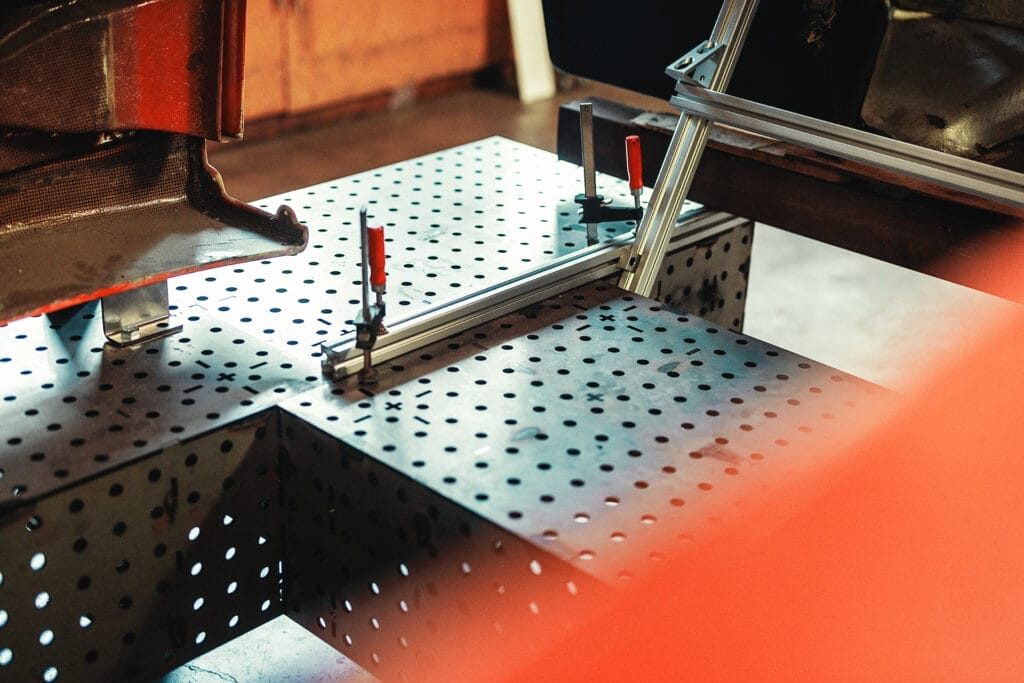

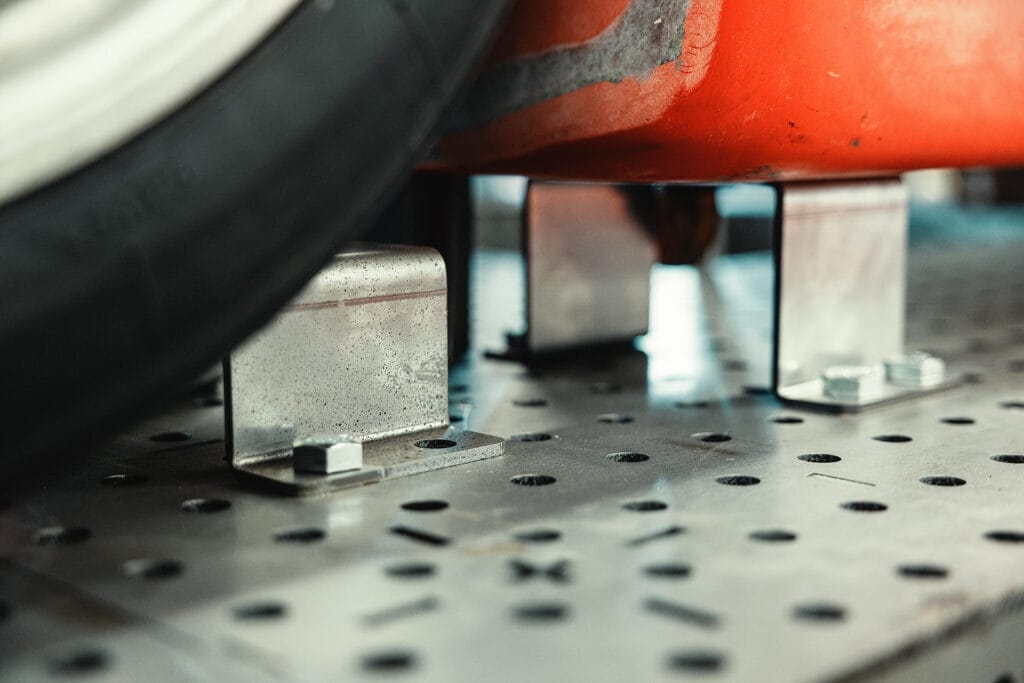

While Mike has thrown the ‘restoration rule book’ out the window, that doesn’t mean it’s going to be easy. He’s starting with the skin, but the entire car has to be built from the ground up. The complete tube chassis and suspension design need to integrate seamlessly, and he’s heavy into research and development for the driveline.

Mike is still in the organization phase, anxiously awaiting shipments to arrive, but he’s already planning how he’ll take advantage of SendCutSend’s services in every way imaginable. While he may prefer to tackle most things as they come up in the build rather than plan out every detail ahead of time, we asked the looming question—where do you start?

Step one is laying the tube work for the chassis and then bringing in the technology. Mike plans to work with a local company for 3D scans throughout the build process. Then, he’ll take all that data, turn to CAD to develop the rest, and bring it to life with SendCutSend.

Episode 1 of F40 Evolution: Chassis Table and Body Setup

For starters, he’s picked up suspension components from a Ferrari 458 Challenge Evo and plans to use the scan data from the underside of this car to map out all the suspension pickup points, replicate them in CAD, and then transpose them onto his custom chassis to design the connections he needs to fabricate.

“[SendCutSend] has become one of the most powerful tools in my arsenal and allows me to bring parts to life I never thought I would even have the means to accomplish at a level of quality I’d spend a lifetime trying to achieve”.

With a blank canvas in front of him, Mike is preparing to design and send out every part, bracket, mount, and component you could (and couldn’t) name to help keep this build on time, on budget, and executed to a level befitting Enzo himself.

Online Sheet Metal Manufacturing Solutions for the Everyday Builder

“You don’t have to know how to use CAD with SendCutSend’s online system,” encouraged Mike. Taking advantage of the Parts Builder is a great way to introduce yourself to building, using templates to design gears, brackets, and basic shapes. “Once you start thinking in 2D, you can begin thinking in 3D,” said Mike.

Parts Builder: SendCutSend’s Free CAD System

Many people fear learning something new or seemingly complicated. Take it from StanceWorks, though. Mike is confident that anybody who sets their mind to it, over a weekend, can become as competent as he is with CAD, capable of designing 99% of what you’ll find on his YouTube channel. “Once you have that toolset, it allows your brain to begin thinking outside the box, and you find new ways you can incorporate that tool.”

Mike has designed chassis rails for a hot rod rebuild, suspension mounts, and seat mounts for previous builds. His latest order was for throttle linkage pieces for a friend’s ITB (individual throttle bodies) setup. “Tiny little pieces that would be so difficult, or impossible to make by hand – lean on [SendCutSend] technology to make your projects better.”

A Long Road Ahead for StanceWorks and SendCutSend

StanceWorks has a long road ahead for the “Yet to Be Named F40” build. Once all the puzzle pieces arrive at the shop, it’s time to mount them to the chassis table and “blast off!” as Mike puts it.

Mike is targeting SEMA 2026 for a showcase with SendCutSend. This isn’t a build you’ll want to miss, so be sure to follow along on Instagram and YouTube for the latest shop antics and project videos!

We’ll be checking in with Mike regularly to learn more about the laser-cut parts and materials that are bringing this build together, and mining for his greatest tips to help get your projects across the finish line!

SendCutSend Is Here to Help

Looking to StanceWorks for a little inspiration? Make sure to check back soon for more on the F40 progress and to see how Mike and the team are turning CAD files into automotive art.

Already bringing your own wild idea to life with Send Cut Send? We want to hear about it! Fill out our Partner with Us form and we’ll be in touch!