Griot’s Motors – Classic and collectible cars, perfected. The laser helped.

Check out the website, cruise over to their Instagram page—even if you’re not a driving enthusiast, the classic cars displayed there will make you yearn for an open road and a full tank of gas. My favorite is the 1960 Fiat 600 Jolly, complete with tasseled roof, wicker seats, and a hot pink paint job. The 240Z (either of them) come in a close second.

Good as new

Whichever car grabs your eye, all have been restored to showroom condition. Most are even better. Way better. And there’s at least one person who’s touched each of them with loving, skillful hands: Forrest Davis, shop foreman at Griot’s Motors in Tacoma, Washington.

For the past ten years, he and his team of restoration mechanics have been busy bringing automotive history back to full-throttled life. They’ve rebuilt engines and exhaust systems, upholstered bucket seats, applied gallons of high-gloss paint and tightened countless lug nuts.

With the help of an online laser cutting company named SendCutSend in Reno, Nevada, they’ve also machined loads of precision laser cut aluminum, stainless steel, copper and brass parts. “We’ve been using them for a couple of years now,” Davis said. “I just upload the drawing to their website, receive an instant pricing, and the parts arrive a day or two later. The service has always been awesome.”

Shine on

If the name Griot sounds familiar, that’s not surprising. Anyone who spends their weekend waxing a vintage automobile or tugging on a socket wrench has at least heard of them, and is quite possibly a repeat customer. Griot’s Motors is a sister company of Griot’s Garage, a leader in the car care industry.

In 1990, founder Richard Griot came up with a more comfortable take on the traditional garage floor creeper. He soon put a new spin on random orbital polishers, followed by a “Speed Shine” detailer, “Pure Freakin’ Magic” microfiber cloths, and more. Today, Griot’s Garage manufactures and distributes hundreds of high-end automotive products.

And because they’re as passionate about automobiles as they are about the waxes, brushes, cleaners, and hand tools used to keep them in tip-top shape, the Griot family decided to expand into the restoration and selling of classic, exotic, and collectible cars. The year was 2010, and Griot’s Motors was born.

Embracing the obsession

For those in the market, you’re too late for the 1973 Mercedes Benz 280SE and the 2006 Ford GT. As you can see on the Griot’s Motors website, they’re long gone. But there’s an awesome 2013 Porsche Boxster still available, as well as a lime green 2013 Dodge Challenger Hellcat and a “Martini 5” Delta Integrale Evoluzione 1 from Lancia, circa 1992. More classics are on the way.

So how did an online laser cutting service enter into this extreme automotive restoration equation? Davis isn’t sure. “I think it was through Instagram, but I honestly don’t remember,” he laughed. “However I found SendCutSend, it was a couple of years ago, right about the time I first started messing around with Autodesk Fusion. I’d designed a part for some project or another and decided to give them a try. It turned out to be the right decision.”

Until then, Davis had been relying on local waterjet and plasma cutting providers for his sheet metal parts. SendCutSend proved to be more economical, faster, and a whole lot more precise.

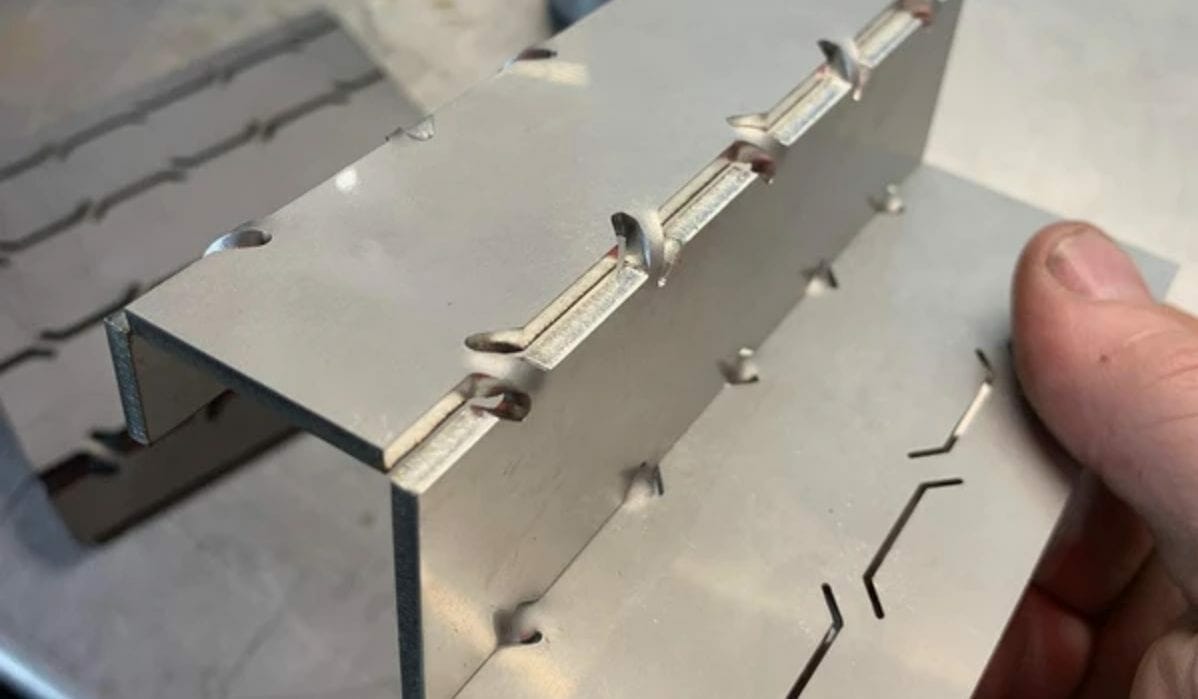

“In order to improve locational accuracy, I’ll often use a tab and slot method to locate mating parts,” he said. “Since switching to a laser cutting service like SendCutSend, I’ve been able to decrease the clearance amounts to practically zero. The parts just slide together with a very nice fit.”

Changing directions

He’s also begun leveraging a technique known in the sheet metal world as “The Wave.” As its name implies, it uses a series of wave-shaped notches that make parts easier to bend. In one recent example, Davis was able to bend even ¼-inch thick aluminum plate using a “regular old sheet metal brake” that would otherwise have been too wimpy.

“We’re putting some aftermarket seats in the 240Z and I needed some mounting brackets, so I incorporated a series of bend reliefs into the drawing and sent it over for laser cutting,” he said. “I’d never bent anything that thick, but it worked out great.”

Griot’s Motors has a well-equipped machine shop and fabrication area, Davis explained, complete with “all the tools we need to make cars better than when they were first delivered.” That said, they do buy off-the-shelf replacement components whenever possible, as this not only brings the vehicle closer to its original factory specs but helps to reduce costs. But a lot of parts, he noted, have to be made from scratch.

“The ability to design something in CAD, upload it to the SendCutSend website, and have a really accurate laser cut part in my hands within a couple of days—that’s definitely changed the game for us,” said Davis. “I consider myself a fabricator before anything else and enjoy reproducing parts that you can no longer get your hands, or creating entirely new stuff. At the same time, though, I’m responsible for the shop and have to ensure that we meet our on-time delivery and cost control promises. SendCutSend helps me to meet all of those goals.”