Exporting your laser cut Inkscape design as an EPS is a simple process. In this video and guide we’ll walk you through the process, including our checklist of items to achieve the best results from your laser cut Inkscape design.

Video Guide to Exporting a laser cut Inkscape Design as an EPS

Setting up Your Inkscape Document for Laser Cutting

For starters, make sure your document units are set to inches, as that’s what we prefer to work with here at SendCutSend.

You will find Units in the Document Properties under the File menu, or with the hotkeys SHIFT + CMD + D.

Inkscape has both Document Units and Display Units. Document Units will change the size of your page. You’ll want to change this to inches. You can also select one of the premade formats, such as US Legal, to change the size of your page.

On the other hand, Display Units will determine what units are displayed in the rulers and other elements of the user interface. This unit can be set to a different unit type, though for simplicity, we do recommend setting it to inches as well. Close the dialog when you’ve completed this.

Scaling and checking your Inkscape file for open contours

Next you’ll want to confirm that your part is in fact at a 1:1 scale. Select the largest contour and double-check that the dimensions are correct for your project. If not, scale the part to the correct final dimensions before proceeding.

To ensure the success of your laser cut part, you’ll want to check your file for open contours and stray points. Inkscape does not offer a way to automatically find stray points. To help, you can go to edit > and use “Select All” to highlight everything in your design. If the selection box appears much larger than your part, be sure to delete any unnecessary points or geometry. You can also use “Select All” to check that everything fits on the page. Saving the design will include only geometry on the page, so make sure there is sufficient room around the design. The size of your page will not matter once you upload to SendCutSend.

Now you’ll be able to check for Open Contours. Head to View > Display Mode > and select Outline. If there are any segments of the design that are not connected to each other, those are open contours and will need to be fixed before exporting the design as an EPS. To do this, use the tool titled “Edit paths by nodes.” You can also use the keyboard shortcut letter “N.” The nodes are the gray boxes you see around the outline of your object. Select the two nodes you want to join. They will turn blue when they are selected. Then select the button to “Join Selected End Nodes with new segment.” This contour is now fully closed and ready for the laser cutter.

Checking over your laser cut Inkscape design file

Next, head to the Layer menu and open the Layer and Objects panel. Before you export, make sure everything is on a single layer, including any text and bend lines.

When your designs include text, be sure that all text has been converted to outlines or paths. Cut-out text or “Reversed text” is required to have “bridges,” or in other words, the text needs to be “stencilized.” For more details, check out our other lesson on preparing your text for laser cutting in Inkscape.

You’ll also want to make sure all non-text holes and cutouts are at least 60% of the material thickness, which ensures they can be cut by the laser.

All of your shapes will need to be Unioned from the Path menu. This is particularly important if you drew shapes that overlapped with each other. Unioning the shapes will ensure they result in one contour for the laser to follow.

Once you’ve run through this checklist, head to the View menu > Display mode > and select Outline. Viewing your design in Outline mode will help you catch any unwanted geometry and triple-check that you have clean and continuous paths.

Be sure to remove everything that you do not want to be cut, including any dimensions or design notes that you may have placed in the file. What you upload to us from Inkscape should be a clean EPS file, with only your desired parts.

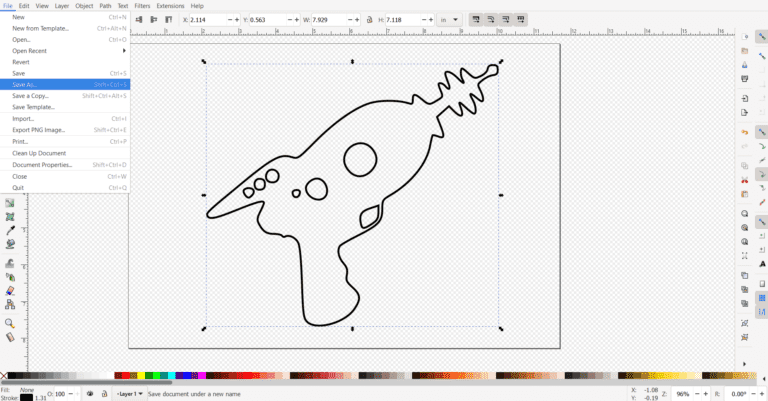

Exporting a laser cut Inkscape design as an EPS

Once you’re ready to export your laser cut Inkscape design, head to File > Save As. You can also use CMD + Shift + S on Mac or CTRL + Shift + S on Windows. Change the name of your file if desired and select the location, such as your downloads folder. Change the file type to “Encapsulated PostScript”, also known as EPS. You’ll then receive one more dialog: if you have text in your design, make sure “Convert Text to Paths” is selected as the output option. Leave everything else as the default options.

Select OK and your EPS will be located at your chosen folder, ready to upload to SendCutSend for laser cutting!

Check out all our other laser cut Inkscape design tutorials, and let us know if you have any questions. Otherwise, upload your file and get instant pricing today!