Threaded fasteners are one of the most common methods of assembling components. They’re available in a wide range of sizes and styles from standard nuts and bolts to much more unique options. In this article we’ll discuss some of those options, specifically studs, nuts, and standoffs.

SendCutSend keeps various sizes of self-clinching studs, nuts, and standoffs in stock and can install them for you. Your parts will show up at your door ready to go.

Let’s take a closer look at these awesome bits of hardware.

Studs, Nuts, and Standoffs: What Is the Difference?

What’s the difference between studs, nuts, and standoffs? They’re all threaded fasteners, but what makes them unique?

Studs

A stud is similar to a bolt. It’s a length of male thread. What differentiates it from a bolt is that it’s attached to the part. The attachment can be done permanently by welding or another similar process. Or the attachment can be semi-permanent, meaning it’s fixed, but could be removed and replaced if it gets damaged. This is usually done by pressing the stud into a precisely sized hole using tools specifically designed to clamp the base metal around the fastener. Typically the stud will have features on it, like serrations, to resist twisting in the hole and a head to resist pulling through the hole. There are also studs that can be welded in place or threaded into a tapped hole.

Why use a stud instead of a bolt? The fact that the stud is secured to the part means you don’t need access to the back side to hold it while you tighten. There may be limited or no access for a tool on the back side. It can also significantly speed up assembly time to have fewer loose parts to assemble.

Why use a stud instead of a tapped hole? Having the stud protruding from the surface has a couple of benefits. It helps to align parts as they’re assembled together and it can hold a part in position as you install nuts. This is especially helpful for heavier parts or parts that need to be assembled in a vertical orientation. A perfect example is the wheel studs on a car. The studs hold the wheel/tire in position as the lug nuts are installed. It would be much more difficult to try to hold all that weight in position and try to line up holes to install bolts.

Nuts

Nut is a bit of a blanket term for a female threaded fastener. They come in a lot of different styles from simple hex nuts to captive floating cage nuts. In general, a nut will be used with a similarly sized male threaded fastener, whether that’s a loose bolt or a stud. Nuts can be loose like a bolt or captive like a stud. Similar to studs, they can be permanently secured or semi-permanently attached to parts. Semi-permanently installed nuts can snap into round or square holes in thin sheet metal or they can press into precisely sized holes with twist-resisting serrations just like studs.

Why use a nut instead of a tapped hole? Sometimes you need both the male and female threaded fastener to be floating to help with alignment. Sometimes the material is too thin to tap. In that case, a self-clinching nut can act like a tapped hole in thin sheet metal.

Standoffs

Standoffs are a little bit different. Standoffs can be male threaded or female threaded (or both, one at each end). The unique feature you get with a standoff is that it can separate assembled components. Two components can be securely assembled together with a precise, even gap between them. This is very common with circuit boards and electronics.

Standoffs can be loose, with threaded features on both sides, or they can be self-clinching on one end to secure to the panel. Self-clinching standoffs work just like self-clinching studs and nuts, they are pressed into a hole using special tooling.

Why use a standoff? The main reason to use a standoff is to get that separating gap between components. You may need clearance for other components, air flow for cooling, or it may just be an aesthetic choice.

Benefits of Hardware Insertion

Self-clinching fasteners are one of the best ways to get threads into thin sheet metal. The base material in thinner sheets is typically too thin to get enough threads to form a strong enough joint. Loose fasteners are an option, but often you’re not able to get a tool on the back side to hold the second fastener. Fitting a cover panel over an opening on a sheet metal enclosure, for example. It would be basically impossible to hold a loose nut on the inside while you tighten the screw from the outside. You could, of course, climb inside the enclosure, but that has the same problem plus now you’re stuck inside an enclosure. With self-clinching hardware, the nuts (or studs, or standoffs) are securely attached to the enclosure and you can single-handedly tighten the mating fastener from the outside. Easy.

How are self-clinching fasteners installed? You have two options here. The first is to purchase the tooling yourself (available from sources like McMaster-Carr) to be able to press the fasteners into place. The installation tool can range from a small hand-held tool to a much bigger and more automated machine. The hand-held tool typically accepts a mandrel for the specific size of fastener you’re installing, so be sure you get all the mandrels you need if you’re installing multiple sizes. If you have a lot of them to install, doing it by hand can be tiring. The larger installation machines are much more expensive, but can quickly install many fasteners without giving you a hand cramp.

This brings us to your second option. Get your self-clinching hardware installed by a professional. This has more benefits than saving your forearms. Self-clinching fasteners require precise holes and installation otherwise they can come loose or even twist free when tightened.

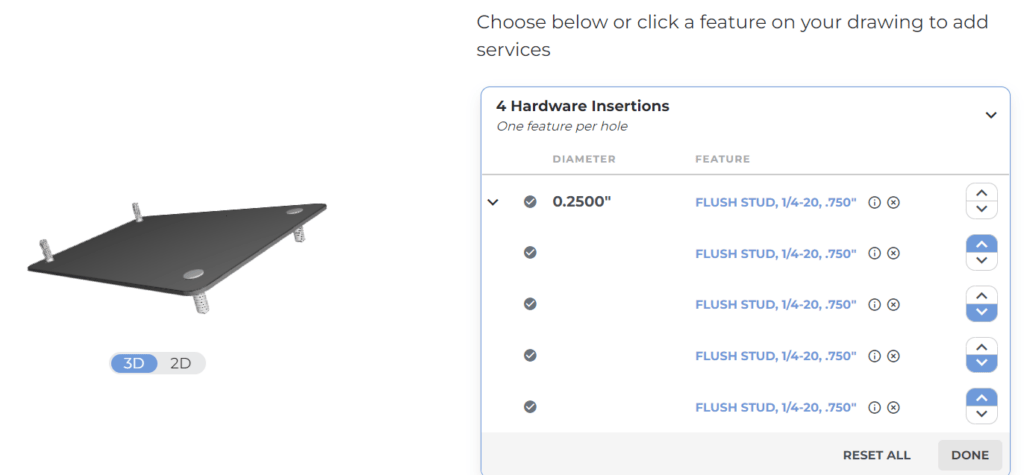

SendCutSend provides the service of inserting self-clinching hardware into your parts for you. The process is simple, you only need to put the correct sized hole in your design and when you configure the part select the Hardware Insertion service. You’ll need to pay attention to which direction you want the hardware installed. This is important for two reasons. First, regardless of whether it’s a stud, nut, or standoff, it will protrude from the surface so you want to know which direction that is. Second, you want the force on the fastener when it’s tightened to pull it into the base material, not out of it. Self-clinching fasteners are pretty strong, but with enough force they can get pulled out of the panel.

Simplifying Your Projects and Skyrocketing Performance with SendCutSend

We hope learning more about studs, nuts, and standoffs will help you utilize their unique benefits in your projects. SendCutSend can install self-clinching fasteners for you with just a few mouse clicks. From cutting, bending, finishing and installing hardware, we can turn your ideas into physical parts shipped right to your door. If you’d like to learn more about our guidelines for these fasteners, you can read it here. You can also browse through the catalog of hardware. If you’re interested in any other services SendCutSend has to offer, check out our website. While you’re there you can submit your designs for a instant pricing.