OnShape is a great CAD software choice for designing your sheet metal or laser cut project for SendCutSend’s services. Once your project is ready, there are a few easy steps to take, then you’ll be able to submit your parts for an instant quote through our online quoting system!

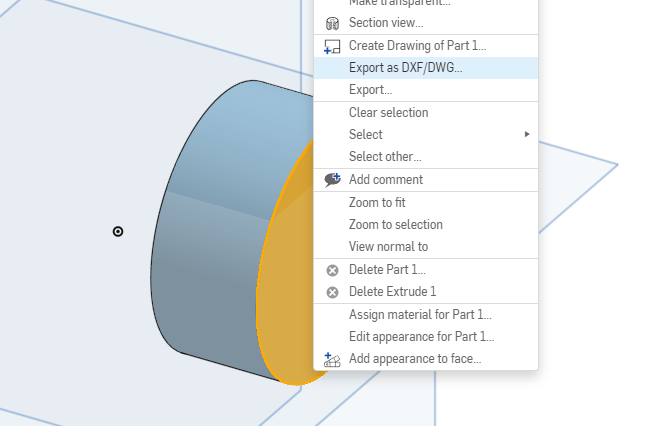

How to export flat parts

Exporting a flat part in OnShape is quick and easy. First you will click the face of the part you want to export. Next, right click on the face of the part, then select “Export as DXF/DWG…”

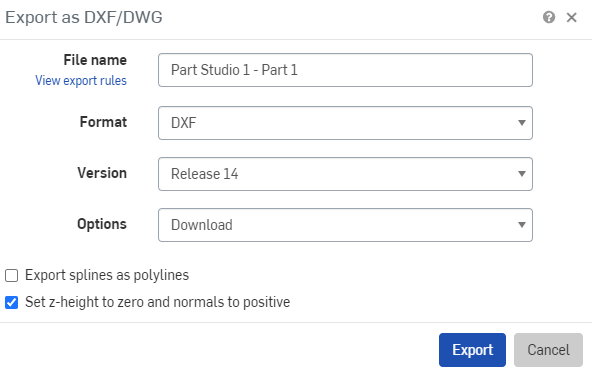

You’ll need to use the default settings listed below in order for your file to meet the needs of our quoting system. These settings include:

File name: Your file name

Format: DXF

Version: Release 14

Options: Download

Do not select “Export splines and polylines”

Select “Set z-height to zero and normals to positive”

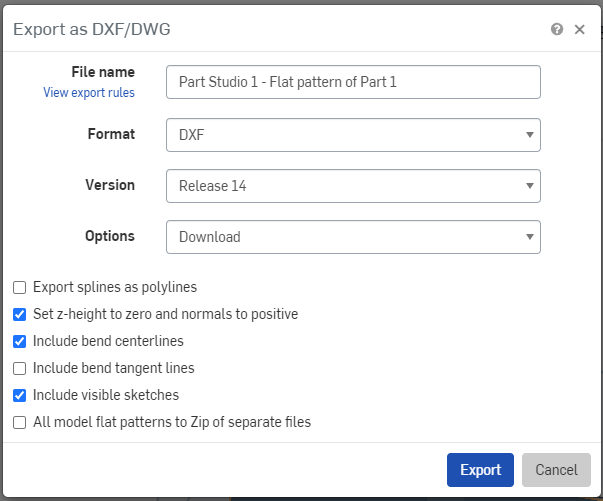

Exporting bent sheet metal designs in OnShape

The best way to set up your bend project is using the sheet metal tools in OnShape. Once your design is ready, enter “Sheet Metal Table and Flat Pattern view” by clicking the button on the right side of the screen.

Next, right click on the face of the part, then click “Export DXF/DWG of Flat pattern…”

Just like exporting a a flat design, please use the default settings as below:

Once you’ve exported your design, upload your file to SendCutSend’s instant quoting tool, select a qualifying material, then configure your bend definitions.

If you need assistance with configuring your bend definitions you can use our bending calculator.

Check out our blog for more CAD tutorials and reach out to our support team anytime for further assistance.