You’ve done the work. You spent hours designing the perfect laser cut product. You’ve prototyped your parts and made the necessary changes and now have a new product ready to send out into the world.

You’ve reached the most important part: marketing your product. Who will buy it? Why will they want it? What makes it necessary to own? And most importantly, how are you going to sell it?

Fortunately, we work with a lot of businesses and our founder is a serial entrepreneur himself. In that spirit, here are some questions you should ask yourself and have answers for if you plan on building a laser cut product with SendCutSend to market and sell.

Who wants it?

Whenever you design a laser cut product to sell, you should be asking yourself why the product is necessary before you start building it. Does it serve a need or fill a gap in the market? If it’s not a brand new product, is there another product out there that does it better or is better known?

The truth is that without an actual need for the product, it will never be anything more than a prototype.

The best way to answer these questions is to do a lot of research and the internet is a valuable tool for such research. Look to see who is building similar products and how their audience is responding to their product. You can learn a lot by following similar brands online and reading the conversations that are happening around the product. This can also help you determine if the market is saturated or wide open for growth. The goal is to avoid finding yourself at the end of product development only to stumble upon a competitor you didn’t know existed.

What is it worth?

Determining your laser cut product’s worth before producing it can be difficult but can save you time and money in the long run. This correlates with doing research on competitors to see what price point they’re selling their products at and whether the costs you put in after prototyping and production will allow you to sell at a price that is worth it. If a similar imported product is not something you can compete with price wise then your design has to be more intrinsic in worth and value.

Sometimes you have to send that product into the world to find these answers, but you can take some educated guesses. This might mean buying your competitor’s product if one exists and testing it out. In this way you can find out how to improve upon it. Maybe a material thickness change or new type of material. Maybe you can improve the dimensions. But you have to make it stand apart from what already exists.

What makes you qualified to sell laser cut products?

Typically, having a background and a following for a certain hobby makes someone better suited to not only design and create new products, but to market them as well. If you’re already involved in the industry and community you’re designing for, you’ve already built a network to start with. It’s also easier to understand potential gaps and what customers could be looking for from your laser cut product.

If you can position yourself as an expert in your field, it’s easier to sell your story, product, and get consumer trust on why they should try your product over others.

What’s your brand?

Perhaps the number one recommendation when starting a business is to define your brand. A brand should have clear goals, clear products, and solid direction. Sometimes a brand will develop but anything you can do to push it along a meaningful path will help. That can mean eschewing some possible products that don’t fit your brand. But mostly it means developing an action statement and sticking to it.

“I intend to make the best grilling products for the everyman grillmaster.”

That is a very clear statement. If you start making kitchen spoons, you’re probably not hitting that goal.

It’s time to market your laser cut product

Once you’ve answered these questions and created the perfect laser cut product, the next step is the actual marketing. This should build on the questions you asked before you even made the product.

If you asked “Who wants it?”, then now is the time to put it before them. Relying on people to find you and send you money will likely not get you too far too fast.

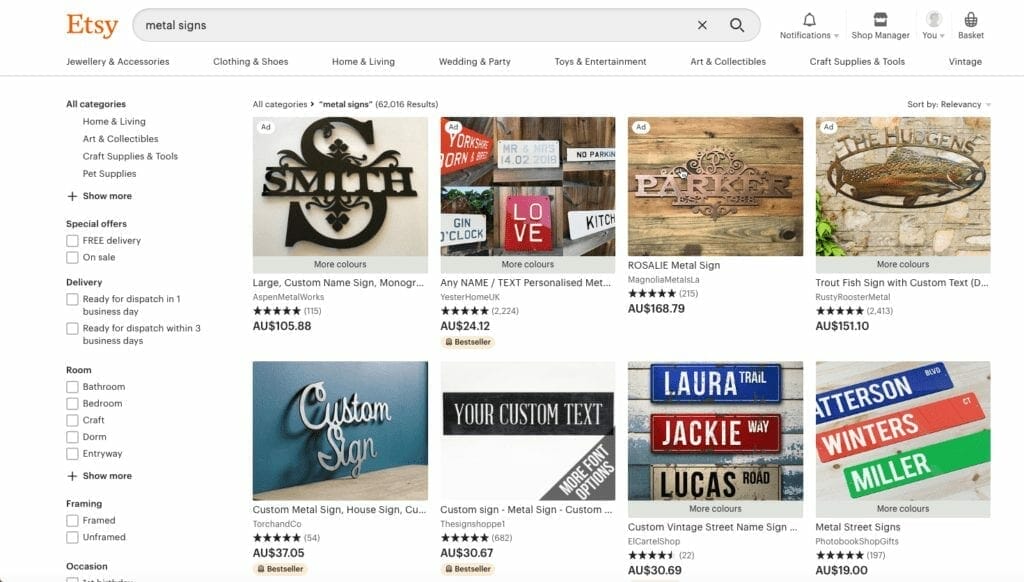

Etsy is good for startups and testing the waters. They charge a fee, but they help with ads and get your product out there and in front of people. Starting your own internet storefront has some upfront costs and difficulty. Etsy puts a professional face on it when you aren’t quite there yet.

Here are some tips for being successful on Etsy or your professional website

- Take great pictures and videos: Use a well-lit room with the same backgrounds and at ground level. You likely can use your phone camera or more professional equipment. Take multiple angles and don’t be afraid to take tons of photos and weed out the chafe. Your photos should show your laser cut product as well as how it works.

- Answer the “what it’s worth” in your product description: Injecting some fun and personality in your product description can make it more attractive. But you may be a serious person and need to convey that. Whatever you write, do it in a way that talks about your product. What problem does it solve? What makes it the coolest product around? Why should people care and want it? This is your chance to answer those questions.

- Set the right price: One recommendation is to price your products higher and then back down. This strategy has risks. Some customers may see it but be put off by the high price and never buy it. The positive side is that you can always change the price and go lower until you find that sweet spot.

- Let people know about your product: There are free and paid opportunities to let the world know your product is out there. You can use social media and forums for free promotion. If you’re interested in paid advertising you can dive into social media advertising or Google ads.

- Have good customer service: The final part of marketing is good customer service. You’ll ideally have a good percentage of repeat customers. Sending parts with burrs or obvious defects is not the way to win over a repeat customer. It also helps to include freebies, hand written notes or to add little touches. It makes the customer feel valued and that they are part of an experience.

You may not be making a laser cut product that is intended for sale. But if you are, following these simple first steps can be a great way to ensure your product’s success as well as gaining the confidence to design and build more!

If you’ve already got your product designed, go ahead and upload it to our instant pricing tool. If you’re still figuring out exactly what laser cut products you want to sell, be sure to review our design guidelines before getting started and check out our post on the 16 best laser cut products for inspiration!