If you’ve been browsing our material catalog and any plastic or metal we offer just doesn’t seem quite to fit the bill, this article is for you. Composite materials are the oddballs of the material world; entirely different from Metals, Plastics, and one another to a point that they are practically incomparable. In this article, we will break down the five composites we offer: ACM (Aluminum Composite Material), Carbon Fiber, Cork (Gasket Grade), G10/FR-4, and Le Phenolic Linen (Micarta), and try to make sense of what these materials are best used for.

Article Contents:

- Overview of all Composites we offer

- Cost Comparison

- Manufacturing Process

- Materials Properties Data Resources

Composites Breakdown

ACM (Aluminum Composite Material)

Manufacturing Process: CNC

Pros:

ACM also known as e-panel or DiBond® is a low-cost, lightweight cousin of aluminum. We offer the material in matte white, matte black, and brushed allowing you to obtain the strengths and aesthetics of aluminum at half the weight. Composed of two sheets of aluminum sandwiched with a polyethylene core, this fire-resistant composite is made out of 80%+ recycled materials making it as sustainable as it is good-looking.

Cons:

As with many of the composites we offer, this material can’t be deburred, bent, tapped, or powder coated and isn’t particularly easy to machine by hand due to the sandwiched nature of its construction. It also can’t be welded in the way that traditional aluminum is so be wary of that if you are a metalworker looking to use ACM as an aluminum alternative.

Typical Uses:

- Used as building cladding in construction

- Visual merchandising

- Machine enclosures

- Framing

Carbon Fiber

Manufacturing Process: Waterjet

Pros:

Carbon Fiber has exploded in popularity over the last few years taking over our cars, bikes, and wallets with good reason. The composite offers an unmatched marriage of strength, rigidity, and light weight to be stronger than steel at a fraction of the weight. Our 2×2 twill weave offering is matte finish, corrosion-resistant, and absorbs impact energy due to its remarkable rigidity. If you are looking for an application that demands some extreme strength, we can’t recommend carbon fiber enough. Additionally, the material we use is a much higher quality than the aesthetic trim pieces you see in many cars nowadays so we recommend diving further into the material and its attributes if you are uninitiated.

Cons:

The biggest advantage to Carbon Fiber is also often its biggest downside depending on your application. The material is so unfathomably rigid that it can often cause problems in larger mechanisms and structures that are designed to flex. While it absorbs impact quite well itself, it can often direct that impact into attached parts which is something to look out for. The other thing to be careful with when choosing carbon fiber is its cost and machinability. The material, especially at higher thicknesses, can get expensive since it becomes increasingly difficult to produce and manufacture as it gets thicker. Because of the cost factor and the way the material is laid, we don’t recommend using this for applications/prototypes that are going to require a lot of machining on your end as drilling holes or cutting it is both quite difficult and can sacrifice a lot of the material’s integrity if not done correctly. If you are doing a large, untested order in carbon fiber, we highly recommend ordering a prototype in an alternate material to make sure everything fits together exactly as needed and before transitioning to carbon fiber. We often consider a test run like that an insurance policy on a substantial order and has saved us on our own projects time and time again. Carbon fiber also cannot be Deburred, Bent, Tapped, or Powder Coated due to its rigidity.

Typical Uses:

- Aerospace

- Dashboards

- Combat robotics protective paneling

- Anything requiring extreme rigidity, strength, and lightweight

Cork (Gasket Grade)

Manufacturing Process: Laser Cut

Pros:

Cork is somewhat an oddball material even inside of the diverse composites lineup. While most of the materials we offer are meant to serve some sort of structural function, cork is used almost exclusively for seals, and aesthetics. The material is incredibly workable, attractive, leak-free, and durable in addition to being one of our most sustainable and environmentally friendly options. Its 10/20 composition makes it great for high compression applications all the way down to low flange pressures and high temperatures.

Cons:

Just like every composite in our lineup, Cork serves a purpose. In this case, a very distinct purpose. Cork’s strength, generally speaking, is about 1/ that of carbon fiber making it not suitable for any sort of strength conducive application. Therefore, we recommend using cork for its typical applications and being wary of using it for anything outside of its general use cases.

Typical Uses:

- High compression applications

- Gaskets and pressured seals

- Automotive

- Plumbing

- Machining

- Decorative and aesthetic projects

- Anti-vibration panels

G10/FR-4

Manufacturing Process: Waterjet

Pros:

G10/FR-4 is widely considered a go-to material for electronics and robotics due to its specialized electrical properties, excellent dimensional stability, lightweight, and fire retardancy. It is the best and most widely used electrical insulator we offer in addition to having incredibly high mechanical strength and rigidity. The material also is resistant to water absorption making it a popular choice for harsh marine environments.

Cons:

G10/FR-4 is often compared to Carbon Fiber due to its similarly woven construction and relatively similar material properties. While this is true, it’s about 25% denser and twice as weak as carbon fiber. This means that while its rigidity, strength, and weight are still exceptional, Carbon Fiber is very much in a league of its own when it comes to these attributes. The other major design consideration with G10 is that the weave differs from that of Carbon Fiber. What this means is unlike Carbon Fiber where the weave is so strong that we can’t measure a difference based on the direction of force, the strength, and rigidity of G10 are going to differ based on whether it’s lengthwise or crosswise against the weave. While that isn’t a major issue, it’s something to pay attention to if you are going to have forces in one direction that are substantially different magnitudes and how the force strains the part as you may want to manufacture your part in a specific orientation. Additionally, this material is not suited for hand machining just like Carbon Fiber so we recommend making sure your designs are completely accurate with a prototype before committing to a large G10/FR-4 order.

Typical Uses:

- Electronic parts

- Robotics

- Marine applications

- Insulating washers and transformer components

- Firearm and knife grips

LE Phenolic Linen (Micarta)

Manufacturing Process: Waterjet

Pros:

Le Phenolic Linen is a high-density mixture of phenolic resin and fine woven cotton cloth that creates a composite with major insulating capabilities and remarkable creep resistance. While these make it a great choice for electrical applications, the material is also impact-resistant, moisture-resistant, and easily machinable. Additionally, LE Phenolic features physical toughness, abrasion, friction, and impact resistances which coupled with great fatigue strength makes it a lightweight alternative to aluminum for many applications.

Cons:

Although Le Phenolic is the second lightest composite we offer, its strength does not hold a candle to materials like G10/FR-4 or Carbon Fiber and we, therefore, do not recommend it for those sorts of use cases. It is, however, very comparable to some of the plastics we offer like Delrin so we recommend considering using it when looking for an aluminum or plastic alternative that behaves remarkably in wet or corrosive environments where aluminum or some plastics may not.

Typical Uses:

- Extremely humid environments

- Where strength is as important as corrosion resistance

- Mechanical parts

- Countertops

- Propeller blades

- Terminal bases & strips

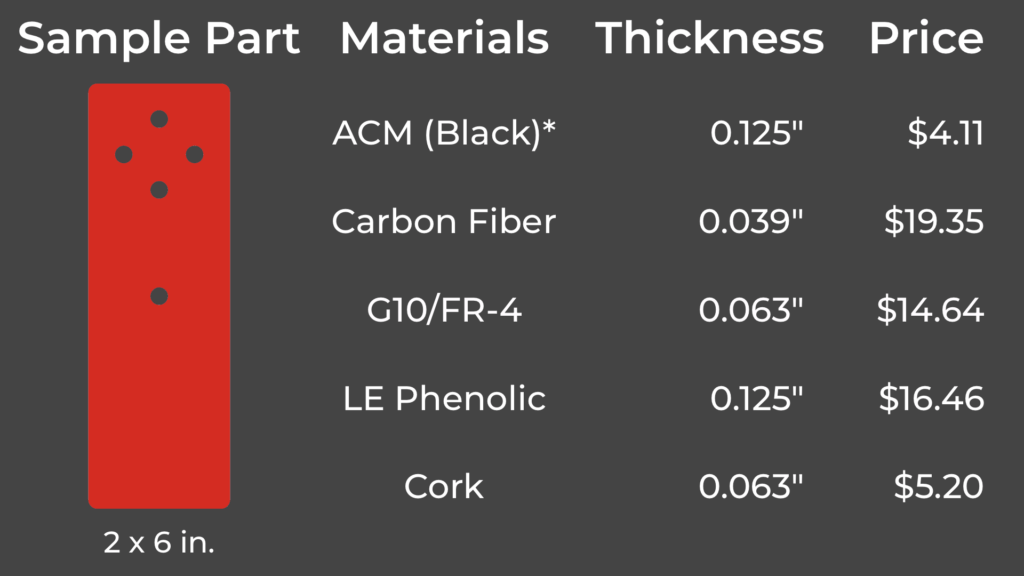

Cost Comparison

*ACM comes in black, white, and brushed finishes which may cause a slight variation in price based on our current stock and demand for the different finishes.

Unlike plastics, comparing costs with composites is difficult to do as each one is used for such different applications. Additionally, each price listed here is given in the thinnest variety of the respective material that we offer at the time of writing. Therefore, you may find that a suitable thickness for your application comes at a substantially different price which is something to keep in mind when comparing these materials. Generally speaking, however, the thinnest option we offer in each material is the thinnest we would recommend going for any application so just keep that in mind. At the end of the day, we don’t recommend picking a composite based on price since Cork is in no way an alternative to Carbon Fiber. We sooner recommend comparing the costs of composites, plastics, and metals you are interested in using our instant quote tool to help you better weigh your options.

Manufacturing Process

One major thing to consider when choosing a composite against a plastic or metal material is the manufacturing process. ACM uses the CNC machine, Cork is laser cut, and the rest of the materials are cut on a waterjet. The vast majority of the materials we offer are cut on the laser cutter so it’s important to compare the CNC guidelines to the laser cutter and waterjet guidelines. Fortunately, the waterjet and laser cut guidelines are nearly interchangeable with few discrepancies and our process handles things like kerf and other complex manufacturing discrepancies. For CNC, however, the guidelines do vary quite a bit and are a little bit more demanding as far as restrictions so we recommend reading those guidelines thoroughly before committing to a CNC-manufactured material as it’s not fit for some scales and design features commonly used for certain applications.

Material Properties Data Resources

Lastly, if you are just looking for a breakdown of all the different material properties and restrictions each composite has, you’ve found the right spot. Below is the table that compares all of the material properties of each composite to help you make the most educated decision you can. We will also include the plastics sheet and the material properties cheat sheet so you can compare our composites against our plastics if there are materials you are deliberating between.

Composites Spreadsheet: SendCutSend Composites

Plastics Spreadsheet: SendCutSend Plastics

Cheat Sheet: Material Properties Cheat Sheet

With the data at your fingertips and the rest of this article to help you weigh your options, we hope you have every tool you need to help you make the right choice for your project. We understand that the biggest challenge of your project should be what comes before and after you order from us and not the ordering process itself. And of course, if you have any questions or things we could do to help make this often difficult process of choosing the right material easier, be sure to contact us!