In this article, let’s take a closer look at the true workhorse of corrosion resistant steels: Grade 304 Stainless Steel. What is it and why is over 50% of stainless steel produced 304 grade? What does it do well, and where is another material a better choice for your custom laser cut parts? Read on!

What is 304 Stainless Steel

Not an area code, 304 refers to the steel’s “grade” where 3xx series indicates that it is in the Austenitic family of stainless steels. Since there are several hundred different stainless steel grades, all separated by a few percent of various alloying elements, it became important to differentiate them with a model number of sorts, rather than saying something like, “this one has 0.1% more chromium than the normal stainless steel.”

Because of its chemical composition, 304 is an alloy that’s weather resistant, very strong but still ductile enough not to crack–literally–under pressure, and easily weldable. It is also relatively easy to form (a great choice for sheet metal bending), has great tensile strength and looks good when cleaned up.

In fact, 304 stainless parts cut on our lasers and deburred on their way to you, typically only require a wipe with denatured alcohol as prep for further fabrication.

304 Stainless Steel Specs

Whether you know it as ASTM A-240, ASME SA -240, UNS S30400, or just plain old 304 stainless, the most significant elements in its composition are carbon and iron, from which all steel is made. Stainless steel gets its unique characteristics primarily due to added chromium and nickel, while Manganese (Mn), Silicon (Si), Nitrogen (N), Phosphorus (P), and Sulphur (S) round out the elemental composition.

Being in the Austenitic family means that 304 is generally less magnetic than Ferritic stainless steels, while being more workable and more “stainless” than Martensitic grades. Duplex and Precipitation-Hardening grades round out the family tree, but are both rather exotic and expensive, making them best for specialty applications.

304 is technically “low-carbon” since it contains less than 0.25% carbon, making it much easier to cold work than higher carbon grades such as tool or spring steel.

Take a look at our 304 material page for a much more comprehensive list of material properties and how they can be bent and formed here at SendCutSend for all your parts.

Appearance

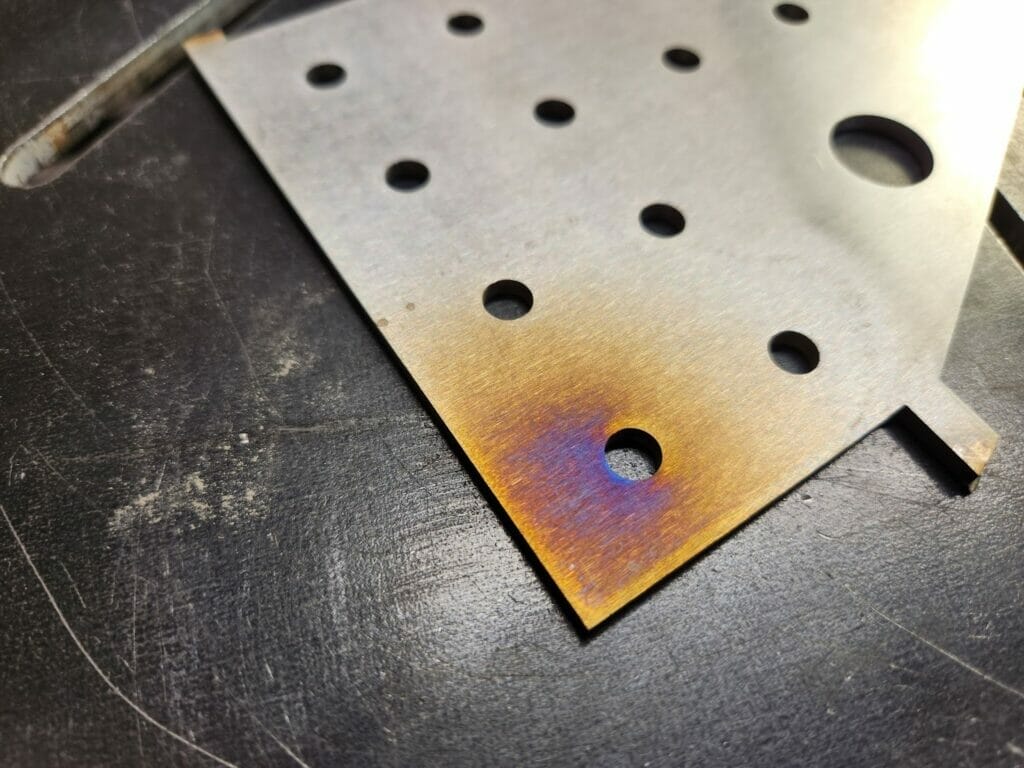

Since 304 is stainless, (or corrosion resistant for our military specifications experts), it isn’t necessary to coat it in a protective layer like galvanizing or plating. This is fantastic, because the fine grain structure makes a uniform surface finish easy to achieve with very little effort. With the proper steps, 304 can also be brought to a high polish, or even blued with careful application of heat.

Of course, it also takes paint, or you can use our powder coating service for a durable, colorful finish.

Fiber Laser Cutting for 304 Stainless Steel

From the thinnest sheet (0.76mm) all the way up to ½” plate, we use our fiber lasers here at SendCutSend to make custom laser cut parts with a tolerance of just 0.005”.

Fiber lasers also have the narrowest kerf of any of our cutting equipment, typically running under 0.01”, meaning that even in a ½” plate, it’s possible to make holes as small as 0.20” diameter without in the surrounding material. Reference the details on the 304 Material Page for a breakdown by thickness of hole, bridge, and edge size.

Worried about calculating for kerf width? Don’t be, when you upload to our app it compensates for the kerf, so you can spend your time coming up with your next great part design.

SendCutSend Finishing Services for 304 Stainless Steel

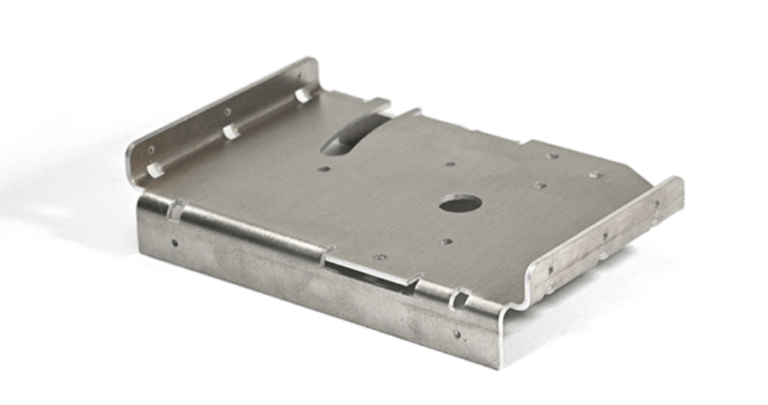

We offer 304 in 10 thicknesses (and counting!) ranging from 0.03” to ½” giving you flexibility in design and allowing you to integrate SendCutSend custom laser cut parts in many applications. To further make integration even easier, we offer a wide variety of additional services for 304.

- Deburring: All but the thinnest sheet are deburred automatically when you order a part.

- Bending: 304 stainless up to ¼” thick can be bent. Check out our processing minimums and maximums to confirm the overall part size and bend length limitations..

- Tapping: If you’ve ever tried tapping stainless steel, you know it’s a job best left to experts (it really is what keeps taps and dies up at night). Check out our tapping guidelines to see which thicknesses of 304 we can tap.

- Powder coating: Of course! In white, red, yellow, green, or three different textures of black.

304 Stainless Steel strengths

Cost

This might sound silly at first, because 304 is perceived as quite expensive, but simply because of economies of scale (remember that 50% of ALL stainless steel is 304) very few materials with comparable characteristics can compete. For a given part uploaded for instant pricing, 304 was approximately 46% less expensive than 316 stainless, 300% less than carbon fiber, and 500% less than titanium for an identical part in a similar thickness.

Corrosion & Chemical Resistance

Because of the chromium oxide layer formed on the surface, 304 isn’t susceptible to rusting (iron oxide formation and flaking) like an ordinary steel would, which means paint or another protective barrier isn’t necessary. This also means that it can be used in high wear areas, such as a handrail, without concern for the finish wearing off.

304 is also quite useful in tank fabrication and is often used in food service due to its resistance to most organic acids.

Tensile Strength

Ever seen that commercial where two trucks pull against each other to see which is stronger? Tensile force is what the chain between them is experiencing. If it was made of 304 grade stainless, not only would it stay rust free in the weather, but due to its high tensile strength among its stainless peers, it would likely also not snap and destroy one of those nice new trucks.

Heat Resistance

Unlike some of the more expensive materials we’ve compared it to, such as carbon fiber, titanium and even aluminum, 304 has an extremely high max operating temperature of about 1600°F (870°C) and it’s not going to melt till around 2550°F.

Weldability

304 lends itself to weldments both because of its simple prep and the ease with which a durable joint can be achieved.

Just about any arc welding processes (TIG, MIG, MMA or SA) can be employed with filler rods such as ER308L and ER 309 being common for all-stainless assemblies. Excellent weld strength between mild and stainless steel can be realized by using an E70S2 or 312 filler rod. A word of caution: Be mindful to minimize heat input (the HAZ) to keep distortion to a minimum.

Machinability

Amongst stainless steels, 303 is most commonly machined, but because it is very common, 304 is often called upon. When machining, cutting tools for stainless should be kept separate and very sharp or the material will gall rather than cut cleanly, leading to tool breakage. Since it also hardens easily, cold working/forming 304 isn’t as simple as with mild steel, but quite possible if best practices are observed. Consider having SendCutSend cut and tap any holes you need, reducing your tooling costs and giving you more time to get all the parts together.

304 Stainless Steel weaknesses

Cost

Yes, you did see cost listed as a strength. Basically, if you need 304 for its material properties, nothing else will do the job as economically. However, if a prototype is what you’re looking for, we offer plenty of other materials that will work great at a lower cost. For simple fitment, consider using hardboard which is quite inexpensive. If you need the metal look but not the strength, try using ACM. If you need a load bearing part that may need modification before the final design, go with mild steel to get very similar strength and weight without the cost.

Warping

Because of its low thermal conductivity and high coefficient of expansion (read: it doesn’t cool off quickly and moves a lot when heated) stainless steel is much more likely to warp than mild steel when heated.

Chloride Environments

For harsh chloride solutions or when the environmental conditions will see it subjected to lots of salt (think, seaside or salted roadways) 304 can develop pitting which can penetrate and continue under the chromium oxide layer.

Common Uses for 304 Stainless Steel Sheet Metal

Its favorable material properties and workability have made 304 Stainless Steel ubiquitous in many industries. It is widely referred to as “food grade stainless” with the common 18/8 moniker simply indicating the amount of chromium and nickel in that particular alloy. (Please note, SendCutSend does not have a food safe manufacturing process.)

304 is also the material of choice in many drawing, forming, and spinning operations, for products such as tubing, tanks, heat exchangers and hoppers.

Other, more novel applications include specialty ultra-high-vacuum components and hydroformed bellows, as well as nuclear vessels.

Whether what you need is a enclosure bent from 0.060” stainless for exterior use, or a piece of ⅜” or ½” plate for a heavy weldment, here at SendCutSend we can get a single part, or 100 of them, to you quickly with legendary service and quality control. Oh, and candy. There’s likely to be candy.