SendCutSend’s ACM, or Aluminum Composite Material (sometimes called e-panel or DiBond®) is a low-cost, lightweight cousin to aluminum. This material should be on your mind if you need something both lightweight and inexpensive. Our ACM (DiBond®) comes in matte white, matte black, or brushed finishes.

Instant quote

A: 1″ x 2″

B: 30″ x 44″

Custom quote

C: 30″ x 47″

.118″ (3.0mm)

.236″ (6.0mm)

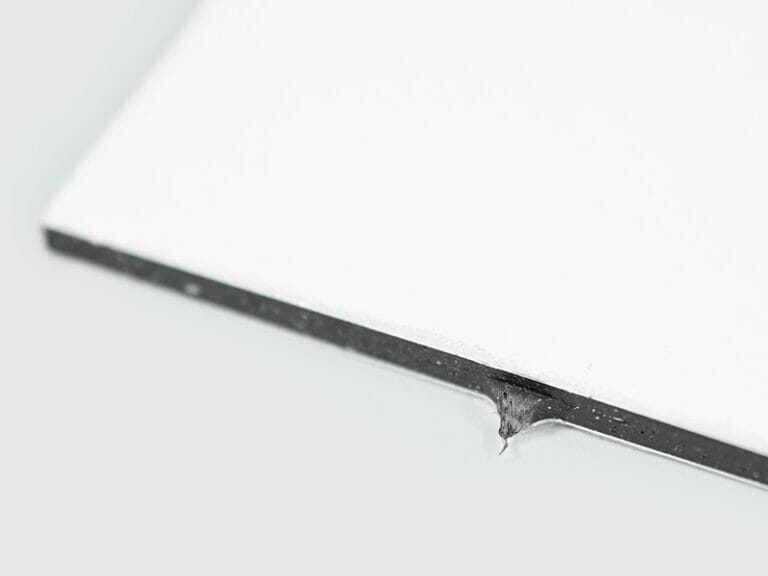

The back side of our brushed ACM has a dull, gray finish. We will cut your file brushed side up.

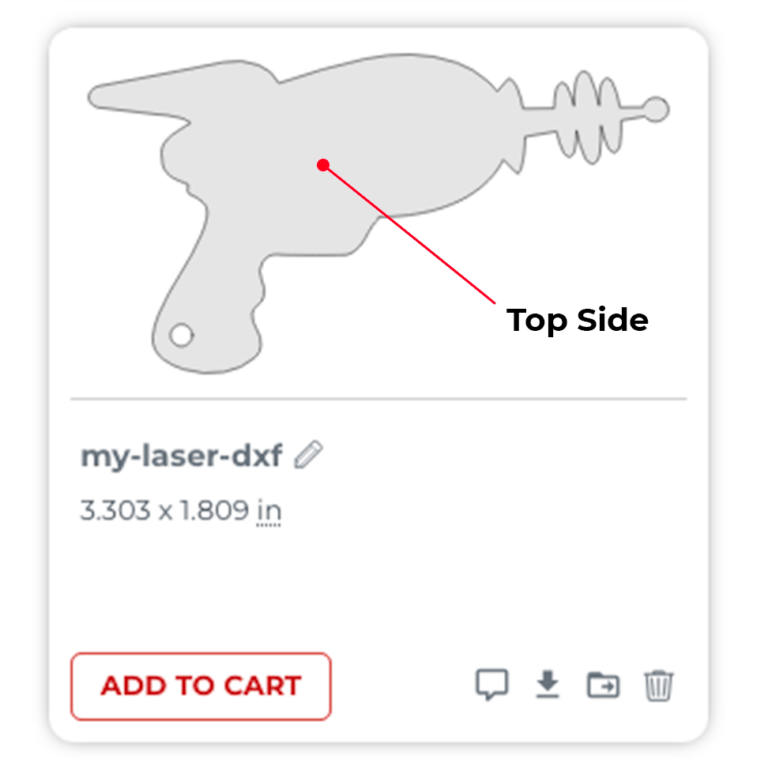

The orientation of your part as shown in the part preview will be considered the top side.

*Please note, we cannot guarantee that brushed ACM parts in your order will all have the same grain direction. Custom grain direction is not available at this time.

These tabs hold your parts in place while being cut to ensure the best accuracy possible. Learn what to expect and how to best design with these tabs in mind.

While ACM Panel looks like aluminum, it weighs half the amount. Often used in construction as building cladding, ACM (DiBond® / e-panel) is a powerful material for obtaining strength and aesthetics in your building renovation, visual merchandising, or machine enclosures.

ACM’s popularity comes from its metallic properties, which are achieved by taking two thin layers of aluminum sheeting and sandwiching them with a polyethylene core. The plastic core allows ACM to be about half the weight of a traditional aluminum sheet, while maintaining desirable characteristics found in solid aluminum alloys.

ACM is made up of around 80% or more recycled materials, so if going green is important to you or your customers, ACM panels are a great choice.

ACM DiBond®, finds extensive application across various industries and architectural projects due to its versatility and durability. Its lightweight nature coupled with high structural integrity makes it an ideal material for a variety of applications.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.