Galvanized steel is a game-changer in the construction world. It’s known for being super durable and rust-resistant, making it the go-to material for a variety of structural and architectural projects.

This article will dive into:

- How galvanized steel is used in construction

- Why it’s so popular

- The different types and services that SendCutSend offers for galvanized steel

Why Galvanized Steel?

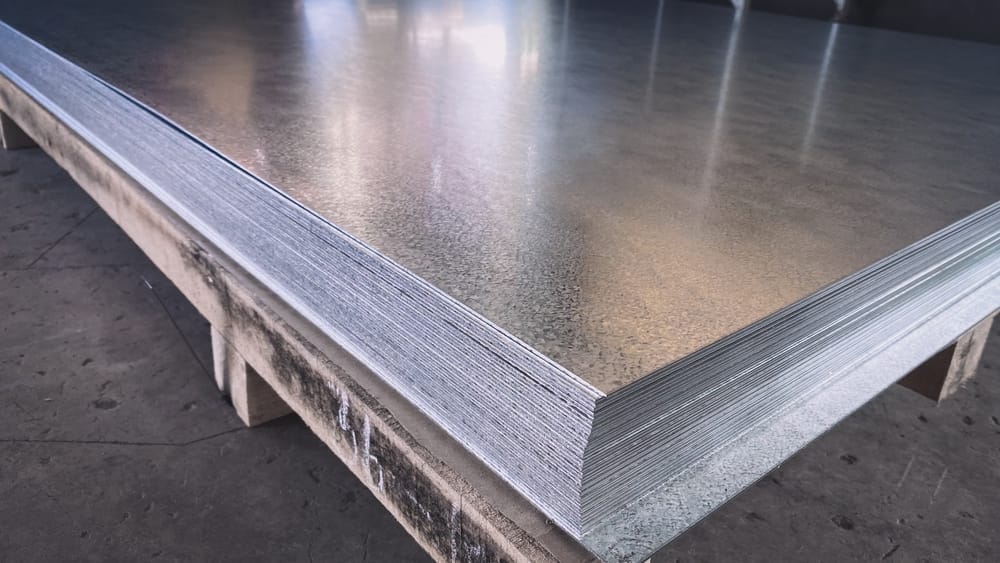

Galvanized steel is essentially just mild steel with a zinc coating. Getting more technical, galvanization is the process of mild steel getting submerged into molten zinc, forming a protective layer to prevent rust and corrosion, making it last longer than plain mild steel and also the biggest reason why it’s an ideal choice for construction projects that require long-lasting materials.

7 Reasons Galvanized Steel is a Big Hit in the Construction Industry

- Corrosion Resistance: The zinc coating acts as a shield, preventing moisture and other corrosive elements from getting in.

- Durability: Galvanized steel can handle tough environmental conditions, making it perfect for outdoor and industrial use.

- Cost-Effective: Sure, it may cost more upfront, but galvanized steel’s longevity and low maintenance saves money in the long run.

- Strength: Galvanized steel maintains the strength of mild steel, all while adding the protective benefits of zinc.

- Environmentally Friendly: It’s recyclable and lasts a long time, reducing the need for frequent replacements and cutting down on waste.

- Versatility: Galvanized steel works well with other materials like wood, concrete, and various metals, as long as galvanic corrosion is managed effectively.

- Sacrificial Protection: If the zinc coating is scratched/damaged, the zinc will corrode first, protecting the steel that’s underneath.

Not everyone knows about sacrificial protection—which is why it’s an important highlight. The zinc coating actually sacrifices itself to save the steel, steering corrosion away from the mild steel underlayer and gives long-term protection without the constant need for upkeep.

Different Types of Galvanized Steel

G90: One of the favorites within galvanized steel is G90, which has 0.90 ounces of zinc per square foot—hence the name. Because of the thick layer, G90 galvanized steel is ideal for structural components, roofing, and outdoor fixtures where durability is a necessity.

SendCutSend offers laser-cut G90 galvanized steel in many thicknesses, with services like bending, hardware insertion, powder coating, and tapping available depending on the material thickness—noting that some operations may not be available for the thinner options.

Other Galvanized Steel Options: There are other types of galvanized steel out there, each with different levels of zinc coating. For example:

- G30 and G60—these offer thinner zinc coatings and are used in indoor or less demanding environments such as metal decking or electronic chassis parts where corrosion resistance is still needed but not as much.

- Galvannealed Steel—combines galvanizing and annealing for a matte finish, perfect for painting and additional processing—often used in the automotive industry where a painted finish is required.

What to Consider When Choosing the Type of Galvanized Steel for Your Project

When choosing the type of galvanized steel, think about the following factors:

- Environmental conditions the steel will be exposed to, such as moisture, salt, and temperature changes

- How long the galvanized steel needs to last

- Any additional processing or finishing that will be applied

- Specific structural loads and stresses that the steel will need to handle

- Compatibility with other metals that are used in the project to avoid galvanic corrosion

- Compliance with industry standards and building codes

Specifically, for construction projects, a thought that gets overlooked when choosing the right type of material is how difficult the part is to fabricate and install, along with the long-term maintenance requirements to ensure the structure’s durability and integrity.

Applications of Galvanized Steel in Construction

As mentioned previously, galvanized steel is super versatile and used all the time in various construction projects due to its excellent corrosion resistance, durability, and cost-effectiveness. Here’s a closer look at where galvanized steel really shines:

Structural Components: Great for constructing beams, columns, and trusses due to its protective zinc coating that extends the lifespan in harsh environments.

Roofing and Cladding: Provides strong, weather-resistant roofing and wall cladding, perfect for buildings since they’re exposed to outdoor elements.

Fencing and Gates: Ideal for making durable, rust-resistant fences and gates that stay looking good with minimum upkeep.

Bridges and Highways: Perfect for bridges and guardrails, handling moisture, salt, and temperature changes without any fuss.

Utility Poles and Towers: Used in utility poles and transmission towers, galvanized steel’s zinc coating protects against corrosion, ensuring the reliability and safety of power and communication lines.

Ductwork and HVAC Systems: Keeps HVAC ductwork from rusting and corroding, maintaining clean air quality and efficient system operation.

Agricultural Buildings: Perfect for barns and sheds, offering durability and corrosion resistance in tough outdoor conditions.

Residential Construction: Used in framing, roof decking, and exterior walls, adding both strength and style to homes.

SendCutSend Available Services for G90 Galvanized Steel

To support construction needs, SendCutSend offers a range of services tailored to galvanized steel. These services include precise laser cutting to get accurate dimensions and complex shapes. Additionally, we provide bending and forming, tapping, hardware installation, and powder coating to ensure high-quality, customized solutions for every project.

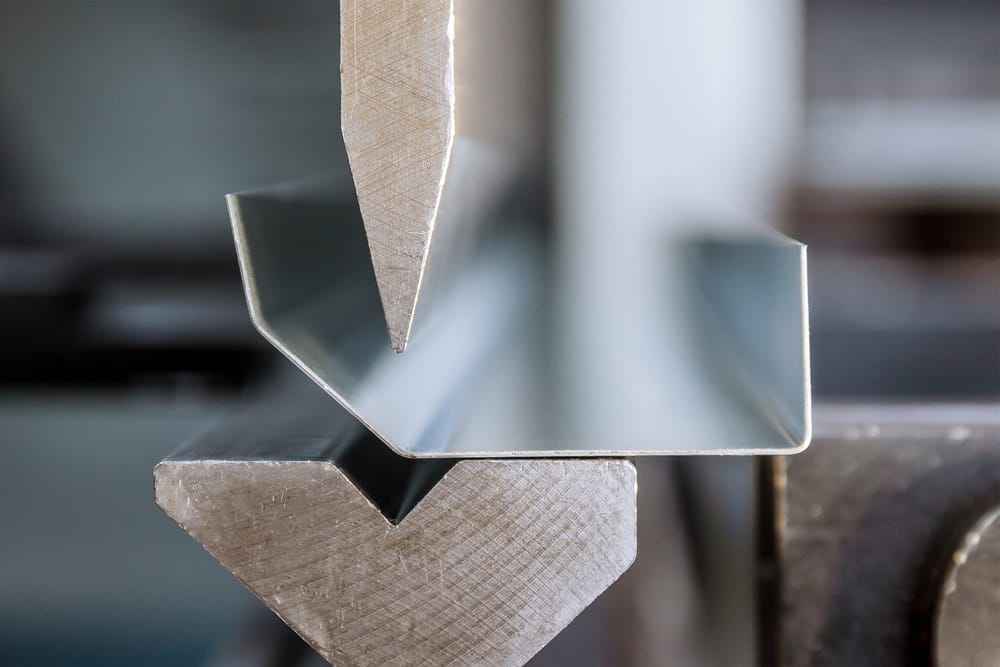

Bending and Forming

The team at SendCutSend uses state-of-the-art CNC equipment and robotics, combined with highly trained staff, to ensure the highest quality bends for customer parts—as long as their parts meet the bending requirements.

Tapping

Tapping involves knowing about thread sizes, fastener types, and selecting the right hole sizes and taps, depending on the material thickness. SendCutSend uses specialized equipment and a team of experts to cut holes and create threads perfectly, ensuring high-quality outcomes for every project.

Hardware Installation

SendCutSend offers efficient hardware insertion services that enhance speed, precision, and overall convenience for customers—no more having to search for the right bolts, studs, or standoffs to use!

Powder Coating

Industry professionals, product designers, and manufacturers prefer powder coating because of its durability and aesthetic appeal. The powder coating on galvanized steel can last up to 20 years even under direct UV exposure, making it a great choice for outdoor and indoor projects where colored finishes matter.

Wrapping Up

Galvanized steel is a superstar in the construction industry for its durability, cost-effectiveness, and versatility. With options like G90 and various other types, it fits a wide range of needs. Whether you’re building structural components, roofing, or outdoor fixtures, galvanized steel is a reliable choice.

SendCutSend offers a wide array of materials and services, ensuring that you get the precise, high-quality results you need for your projects. By choosing galvanized steel, you’re investing in materials that promise longevity and minimal maintenance, making it a smart choice for any construction project.When you’ve got the green light for a galvanized steel project, upload your design and get your instant pricing from SendCutSend today!