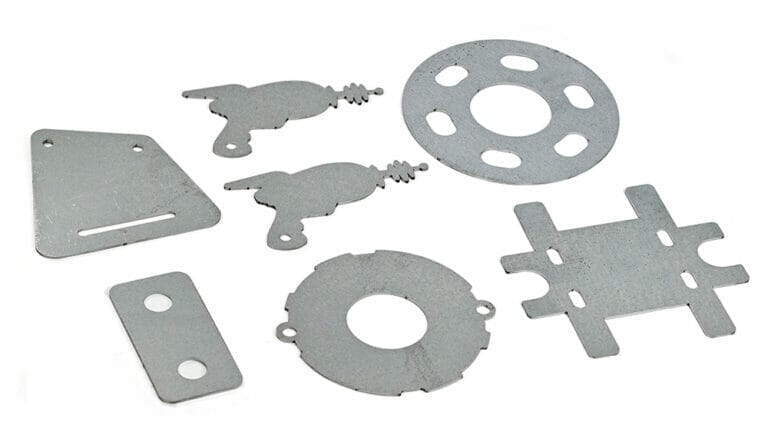

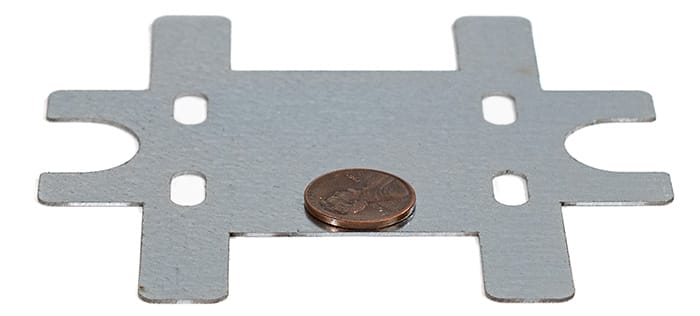

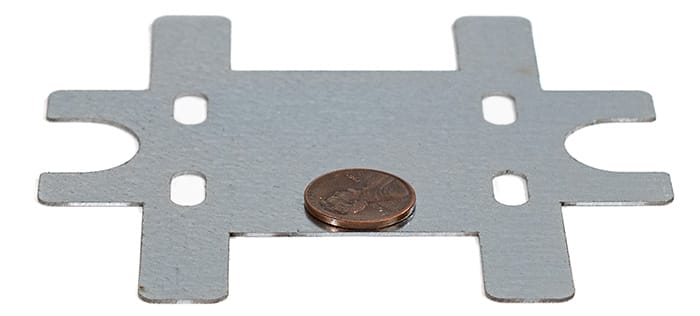

Laser cut G90 galvanized steel offers enhanced corrosion resistance, making it a preferred choice for a wide range of applications, including outdoor and marine environments.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 56″

.030″ (0.76mm)

.036″ (0.91mm)

.048″ (1.22mm)

.059″ (1.50mm)

.074″ (1.88mm)

G90 steel, a hot-dip galvanized steel with a coating weight of 90 grams per square meter, offers a myriad of benefits in various industrial applications. Ideal for outdoor applications like construction and automotive components, it combines durability with visual appeal. Its formability and weldability streamline manufacturing processes, while the zinc coating enhances overall strength. The longevity of G90 steel not only ensures durability but also contributes to sustainability by reducing the need for frequent replacements, making it a preferred material for diverse industrial uses.

G90 steel is a go-to choice for various applications spanning different industries. Since it doesn’t rust easily, it’s an ideal material for outdoor and marine environments.

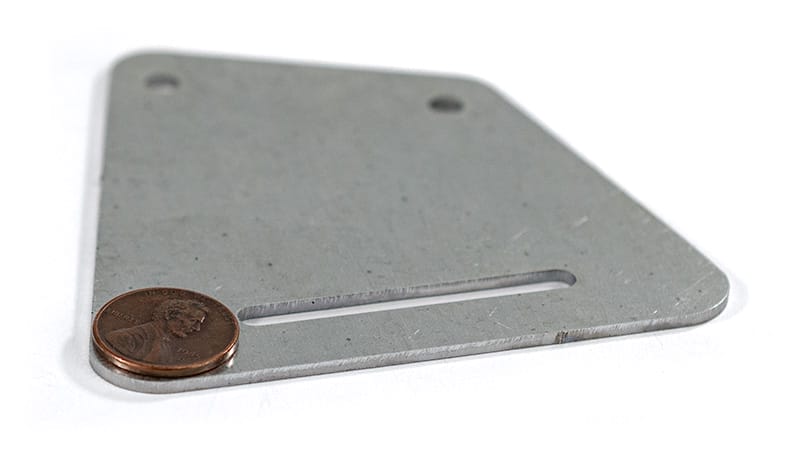

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

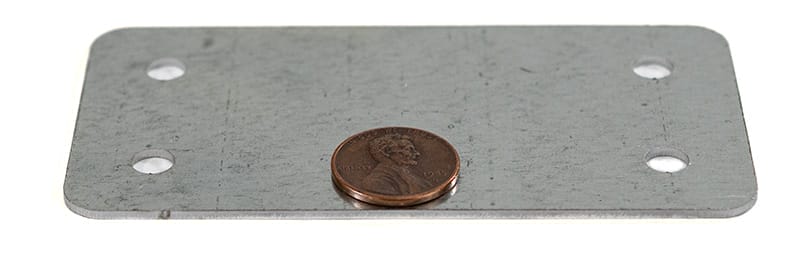

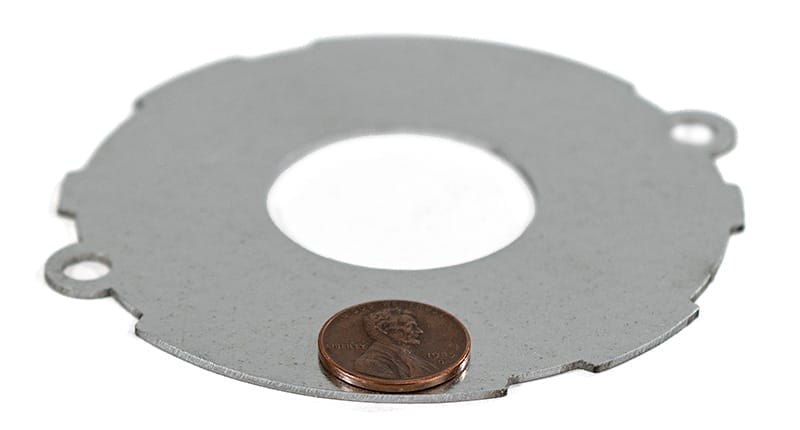

This material is available in five thickness options: .030″ (0.76mm), .36″(0.91mm) .048″ (1.22mm), .059″ (1.50mm) and .074″ (1.88mm).

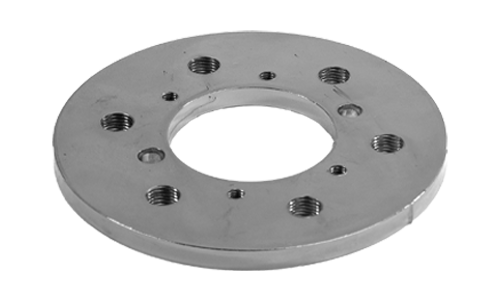

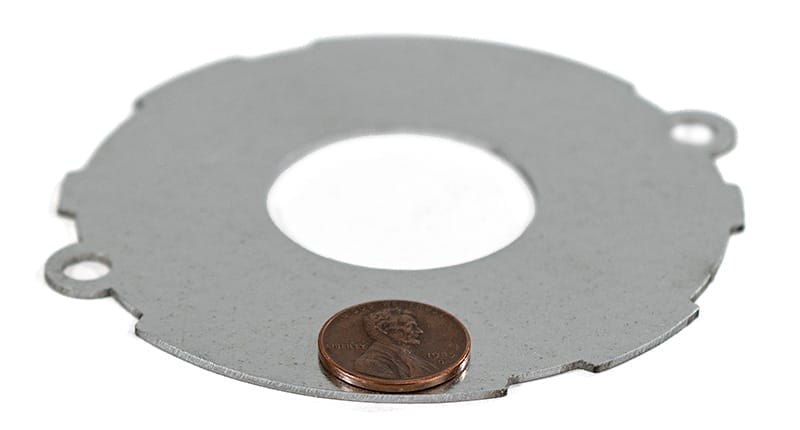

SendCutSend cuts G90 Galvanized Steel in a broad range of sizes and thicknesses. Instant quoting is available for parts as small as .25″ x .375″ and as large as 30″ x 44″. Larger parts, up to 30″ x 56″, can be ordered through a custom quote.

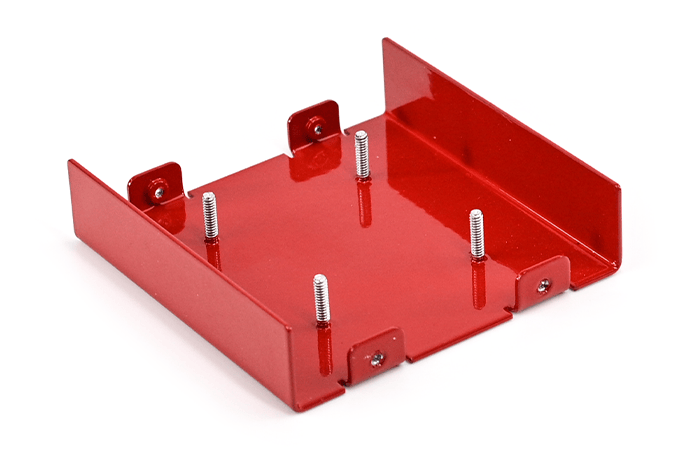

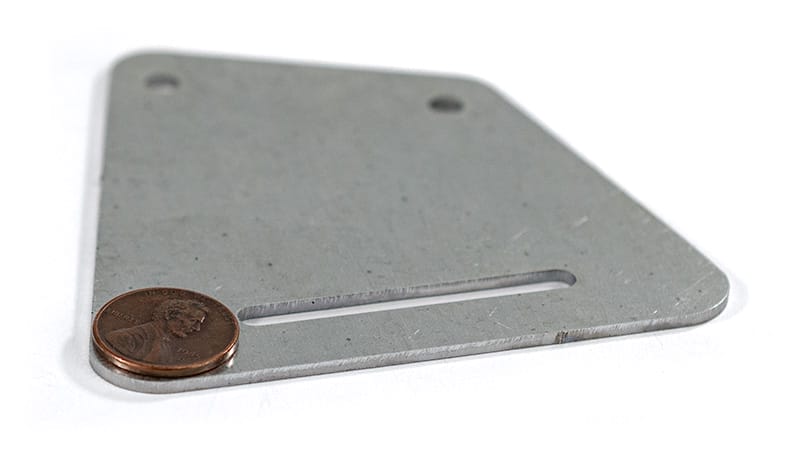

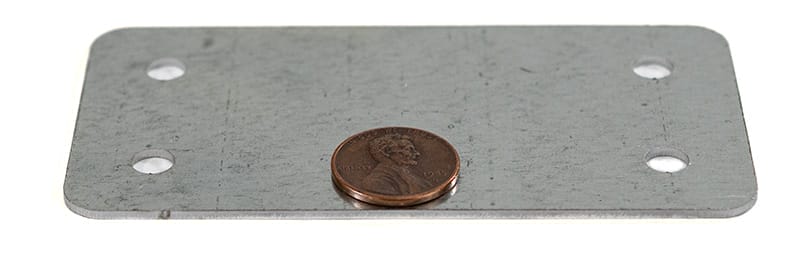

You can add the following services to your G90 Galvanized Steel parts:

Bending, Dimple Forming, Hardware Insertion, and Tapping