Wave bending sheet metal is a clever and accessible hand fabrication technique that’s gaining popularity among hobbyists, engineers, and professional fabricators. In this post, we’ll walk you through the essentials of wave bending, sometimes called smile bending or industrial origami, so you can start experimenting with unique bends and folds that aren’t possible with traditional CNC brakes.

The Best Way to Bend Sheet Metal By Hand – Wave Bending Video Guide

What Is Wave Bending Sheet Metal?

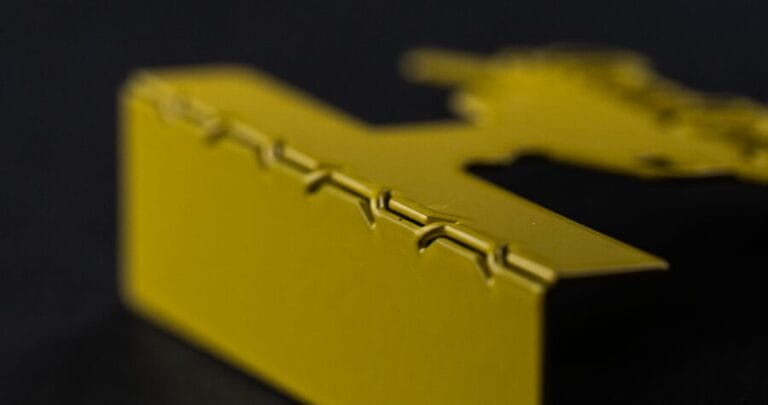

Wave bending involves cutting a wave-shaped or curved perforation pattern into sheet metal to create a controlled weak spot. This allows the material to be hand-bent along the pattern, giving you more creative and functional flexibility with your projects. People use it for designs that a traditional brake can’t handle due to clearance or complexity, for workholding, or when self-fixturing is helpful for welding and assembly.

Why Use Wave Bending Instead of Traditional Bending?

- Tight or Complex Bends: When angles fold back on themselves, a standard press brake can’t always reach.

- Unknown Bend Angles: You can adjust by hand for perfect fit.

- Flat Shipping: SendCutSend ships products flat-packed. With wave bending you can assemble and bend them at home. This is great for things like DIY stands or custom parts.

- Self-Fixturing: Useful for welding, the tabs hold pieces in place while you tack weld.

Keep in mind, while wave bending adds flexibility, it trades some strength (and sometimes cost) for hand-workability.

Does Wave Bending Save Money?

Not usually. The process replaces some press brake time (and setup costs) with increased laser cutting time to create the perforations. This is a trade-off—sometimes it’s worth it for geometric flexibility, but don’t expect big savings on your quote.

How Strong Are Wave Bends?

A bent, perforated seam generally isn’t as strong as a solid, press-braked bend. The more metal you remove (more or wider “smiles”), the easier it is to bend—but the weaker the joint. Thicker webs (the solid areas between the waves) will be stronger but harder to bend by hand.

Wave Bending Design Basics

Rule of Thumb for Web and Cutout Size

- Web (Tab) Width: Start with a width equal to the material’s thickness. For example, if you’re using 0.104in (104 thou) mild steel or aluminum, make the tab between waves also 0.104in.

- Cutout (“Smile”) Width: Match the material thickness. This lets the metal compress instead of stretch, promoting a cleaner bend with less risk of splitting or cracking.

If you go thinner with your webs (for instance, 50% of material thickness), bending becomes easier—but at the expense of final part strength and risk of cracking.

Material Type Matters

- Aluminum (especially 5052): Softer and easier to bend than mild steel, so you can afford to go a bit thicker with your tabs for added strength.

- Hard Alloys (like 6061 or 7075): Harder to bend, but wave bending makes it possible. Companies like Ronin have advanced this method for “unbendable” alloys.

- Thickness Limits: For material thicker than 0.187in (3mm), wave bending gets tricky. Cracking risk increases, so stick with thinner sheets for best results.

Design Pitfalls to Avoid

- Too Many Waves: Makes bending easy but joints weak.

- Too Few Waves: Hard to bend and may require Superman-level strength.

- Long Flanges: The wider the flange you need to bend, the harder it gets by hand—factor in your own grip strength or enlist a friend.

- Straight vs. Wave Patterns: Twisting “waves” distribute stress better than simple straight dashed perforations, minimizing cracking.

Planning a Strong Wave Bend

- Select a web width equal to your metal’s thickness.

- Match the cutout (“smile”) width to the material’s thickness.

- For more strength, use thicker tabs and fewer waves.

- For easier bends, use thinner tabs and/or more waves—but expect reduced durability.

Alternatives to Wave Bending

- CNC Bending: If possible, always use a CNC brake for maximum accuracy and strength.

- Manual Press Brake: Offers more flexibility than CNC, but less consistent.

- Vise and Hammer: A budget alternative for simple bends—just be careful not to damage your part.

- Score-and-Bend: Carefully grinding away some thickness with a cut-off wheel helps with thick material, but is less consistent and riskier.

Experiment and Prototype

If you’re new to wave bending sheet metal, order some test coupons, experiment with different patterns, and see what works best for your material and application. The best way to dial in your “recipe” is hands-on trial and error.

Ready to Try Wave Bending?

Upload your DXF or STEP file at sendcutsend.com for instant sheet metal cutting quotes. We make it easy to go from idea to reality, whether you’re building a flat-pack project, working on a custom bracket, or just exploring wave bending for the first time.