Designing a tapped part requires a few key elements to ensure success. To make sure your part aligns with SendCutSend’s recommendations and requirements, follow the tapping guidelines found on our website. Watch the video and follow along with the transcript below to get started!

Video Guide to Designing Parts for Tapping

Choosing Hole Size and Thread Engagement

If you scroll through the tapping guidelines, you’ll find some important information to go over before placing your tapping order. However, this guide will specifically go over Choosing the Correct Hole Size, and more importantly, the Thread Sizing Chart.

There are two different kinds of columns on the Thread Sizing Chart: Imperial and Metric taps, and the drill size that correlates to 50% or 75% thread engagement.

Thread engagement is one of the most important aspects of designing parts for tapping. Thread engagement is the measurement of how much surface contact you have between the male and the female threads. 50% thread engagement means about 50% of the thread length on the two tapped surfaces have contact, while 75% thread engagement is more contact between the two threaded surfaces: the hardware and the tapped part. 75% thread engagement adds strength in the threads, but can also be more prone to sticking, gawing, or breaking the tap. We recommend staying between 50% and 75% thread engagement for hole sizing.

Look at ¼-20 as an example in the chart: if you have a 0.201” diameter hole, you’ll have a 75% thread engagement. If you have a 0.219” diameter hole, you’ll have 50% thread engagement.

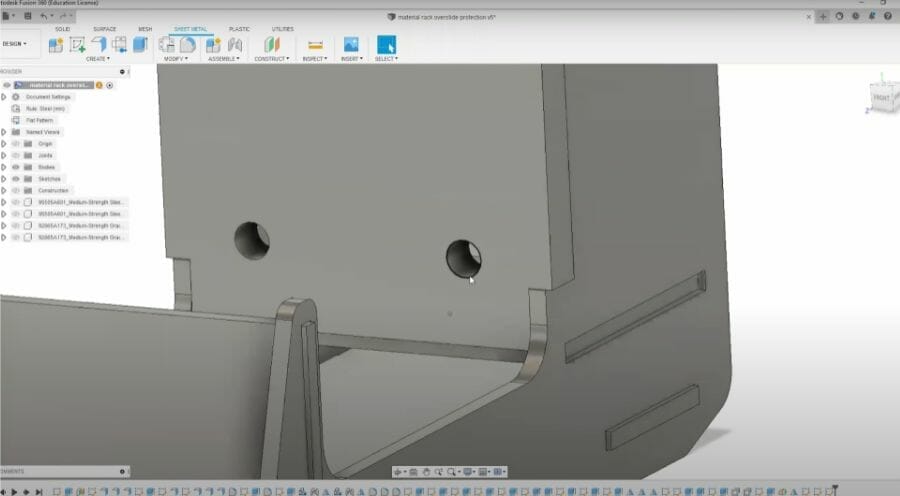

As you’re thinking about thread engagement while designing your parts, keep in mind that we have tolerances built into the laser. This example part has a ¼-20 hole, and we need to size this hole according to that chart. We recommend oversizing the tapped hole by about 0.003” to give room for the +/-.005″ tolerance of the laser while still falling within the range of what is necessary for 75% thread engagement. The most important thing is staying within that window to have a properly tapped hole.

Ordering Tapped Parts

Now that you know how to select hole size for tapping and are familiar with thread engagement, you’re ready to upload your files for instant quoting! Pricing starts at $3 per tapped hole and quantity discounts are available as soon as you order more than one of an identical part.

Get your files uploaded and see an instant pricing today!