In this tutorial we’ll show you how to merge, unite, weld, and exclude objects for laser cutting in Illustrator.

Making sure your objects are combined correctly is important for laser cutting. Using the tools in the Pathfinder Palette, you’ll be able to combine shapes and remove them from another – resulting in clean, closed paths. We recommend exploring these commands on your own and discovering how they can help. We’ll go over the two most used and most important tools in this tutorial.

Welding/Merging Shapes

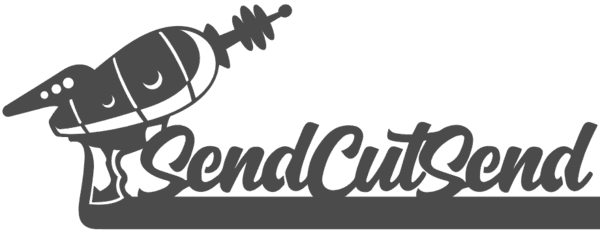

We will start with how to combine and unite objects for laser cutting, which is best shown by example. Let’s pretend you’re me and you want your logo cut out on a nice little stand. You’d start with something like this:

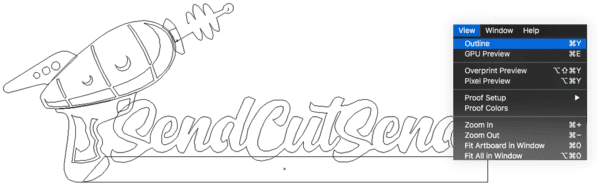

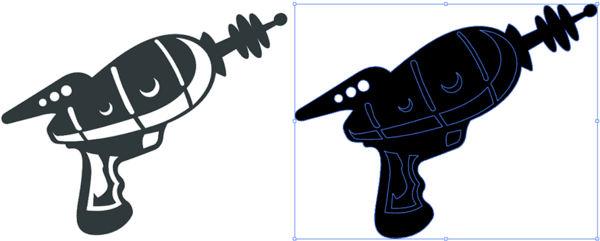

Looks great, right? Well, before we get too excited, let’s view our design in Outline mode (CMD/CTRL + Y.) (I suggest doing this numerous times as you’re designing.)

Uh oh, see all those overlapping lines? We’ve got multiple objects all piled on top of one another, a couple of stray points, an open contour, and a line that isn’t connected. Luckily there are easy ways to combine all these.

Select the whole group of objects and open your “Pathfinder Palette.” Click the “unite” tool. Select all the objects again and you’ll see that everything is connected and nothing overlaps. Now you know how to combine and unite objects for laser cutting in Illustrator!

Excluding Shapes (making holes)

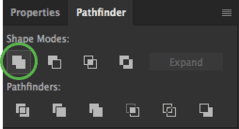

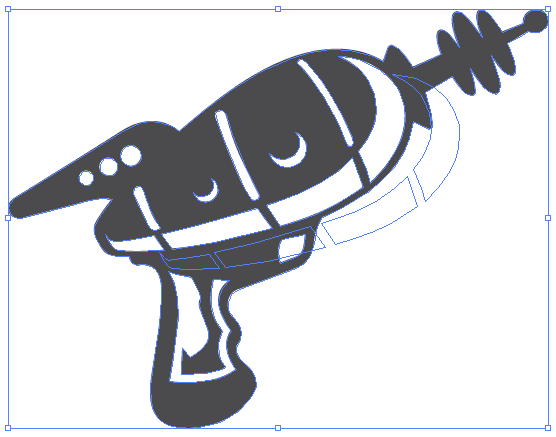

The example above was pretty simple because I had already made use of the “exclude” tool, so we still need to learn how to exclude objects for laser cutting. The exclude tool lets you reverse one shape out of another while making it all one object. For this example we’ll just look at the laser gun.

To start, I basically have one gray shape that has white shapes layered on top. The white shapes are what I want to have cut out of the material by the laser-cutter. Now if I select all and apply black, it becomes obvious that there aren’t actually cut lines for the holes in the part. It’s just layered shapes. I need to exclude the white shapes out of the laser gun in Illustrator so when the part is sent to the laser, the correct paths are recognized for cutting. All we have to do is select both the base and the hole shapes, find the “Pathfinder Palette,” and click the “exclude” tool.

Now I have one shape with the appropriate areas cut out from the main shape. One thing to keep in mind when using the exclude tool is that you may end up with some empty shape objects. An easy way to check is to move your main object slightly and select all. You’ll quickly see if you have any empty shapes. Just delete those extras and you are now an expert on how to exclude objects for laser cutting!

Last steps

After you exclude, unite and combine objects for laser cutting in Illustrator, save your design as an .ai file and upload it to our instant pricing generator. Before you upload your file, go through the final checklist to make sure your file is ready to be cut.