Tap your parts as low as $0.50 per park in bulk.

Save up to 70% or more with quantity discounts! We calculate quantity discounts based on several factors including material, operation type, number of operations on each part and number of duplicate parts. Our app will automatically provide quantity discounts based on your order.

Check out our processing page for information about typical lead times for tapping and other services.

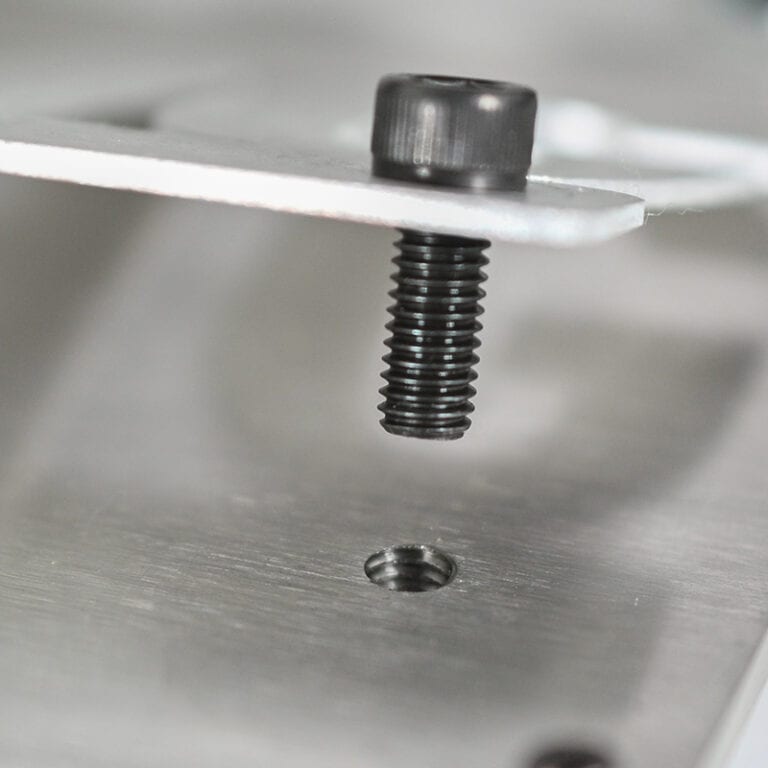

Thread engagement is essentially just a fancy way of saying, “what percentage of threads on this bolt are engaged (or joined properly) with the threads on this nut?” It works the same for tapped holes and their appropriate fasteners. What’s important here is knowing your materials.

To make sure your parts have the required strength for your applications, you must be sure to take note of factors like tension and shear.

Thread pitch is a measurement depicting how many threads are in a given space. There are a few different ways to represent thread pitch:

Diameter is simply a line of measurement crossing directly through the middle of your geometry, which, in this case, is your hole to be tapped and the fastener to be used.

SAE is represented by this format: ½-20. This measurement is read as a half-inch diameter with 20 threads per inch of the tapped length.

Metric is represented by this format: M10-1.5. This measurement is read as a 10mm diameter with 1.5mm between each thread. So, rather than counting threads per inch, the metric system directly measures the distance between two threads in mm.

ANSI is a unique beast and has its own standardized sizes that read like this: 10-32. These, like the other two systems, just reflect a particular standardized fastener size. If you need one of these, you likely already know, and if you aren’t sure, there are charts to verify dimensions in detail.

You also need to understand the difference between coarse and fine threads concerning your project.

Fasteners/holes with coarse threads have larger pitches compared to fine threads. This just means there are fewer threads per fastener/hole. In contrast, fine threads tend to have smaller pitches and, therefore, more threads. Easy enough, yeah?

In most cases, you’ll likely be using coarse threads, but there are some scenarios in which the use of a fine thread hole/fastener would be preferable.

If you’re considering whether or not to use a fine thread tap, consider these pros and cons, but understand that this is not an exhaustive list:

At SendCutSend we automatically resize holes to perfectly fit the tap you need! That being said you’ll still want to reference our hole size chart when calculating the minimum distance required from other cut features.

We’ll need the center of any tapped holes to be at least the following distance from other cut features: tap hole size/2 + the minimum tap hole-to-edge distance for the chosen material.

The minimum hole-to-edge distance is measured from the edge of the tapped hole to the nearest cut feature, and the specification can be found on each individual material info page by stock thickness.

Below is a chart of SendCutSend’s available tap sizes. Each tap size is paired with the required through-hole size that will be needed in your design.

Use the formula above to make sure there’s sufficient distance between tapped holes and other cut features to ensure optimal performance for your applications.

| Thread/Tap Size | Hole Size (in) | Hole Size (mm) |

| 4-40 | 0.091″ | 2.32 |

| 6-32 | 0.116″ | 3.00 |

| 8-32 | 0.138″ | 3.51 |

| 10-32 | 0.164″ | 4.17 |

| 1/4-20 | 0.209″ | 5.31 |

| 1/4-28 | 0.221″ | 5.62 |

| 5/16-18 | 0.266″ | 6.76 |

| 5/16-24 | 0.278″ | 7.07 |

| 3/8-16 | 0.323″ | 8.21 |

| 3/8-24 | 0.341″ | 8.67 |

| 1/2-13 | 0.435″ | 11.05 |

| 1/2-20 | 0.459″ | 11.66 |

| M2 x 0.4 | 0.065″ | 1.66 |

| M2.5 x 0.45 | 0.083″ | 2.11 |

| M3 x 0.5 | 0.102″ | 2.60 |

| M4 x 0.7 | 0.134″ | 3.41 |

| M5 x 0.8 | 0.170″ | 4.32 |

| M6 x 1.0 | 0.203″ | 5.16 |

| M8 x 1.25 | 0.274″ | 6.96 |

| M10 x 1.5 | 0.344″ | 8.74 |

Please note, the hole sizes per tap size listed in our thread/tap size chart are specific to our tapping service. If you plan to tap parts when they get to you, we recommend referencing the hole size charts provided by the manufacturer of the taps you will be using.

Ideally, you want as much thread engagement/depth of thread as possible. Depending on the application, you may be able to get away with much less. For the best strength, you should try to aim for 1-1.5X the bolt diameter to depth ratio.

For example, an 8-32 bolt should have roughly (0.136”-204”) thread/material depth.

We hope this guide helps you design your parts for greater success with us, and we ask that you take the time to check out the other guidelines pages to make sure everything looks great. In the end, it will save us all a tremendous amount of time and energy!

If you have specific questions regarding your design and they aren’t covered in our guidelines, don’t hesitate to reach out to our support team. Our friendly and talented folks will get back to you as soon as possible!