In the world of 2-axis manufacturing, laser cutting is king. Laser cutting has capabilities that other machining and manufacturing methods can’t replicate, as much as they might try.

The manufacturing industry is continually innovating in the laser cutting space, and SendCutSend is at the center of it all. With our growing arsenal of subtractive machining methods and the constant upgrades we bring to our laser cutters, we’re making it easier than ever to have on-demand machining available right at your fingertips. Let’s go over some of the most valuable capabilities of laser cutting, including cut quality, geometry, and speed.

Cut and Edge Quality

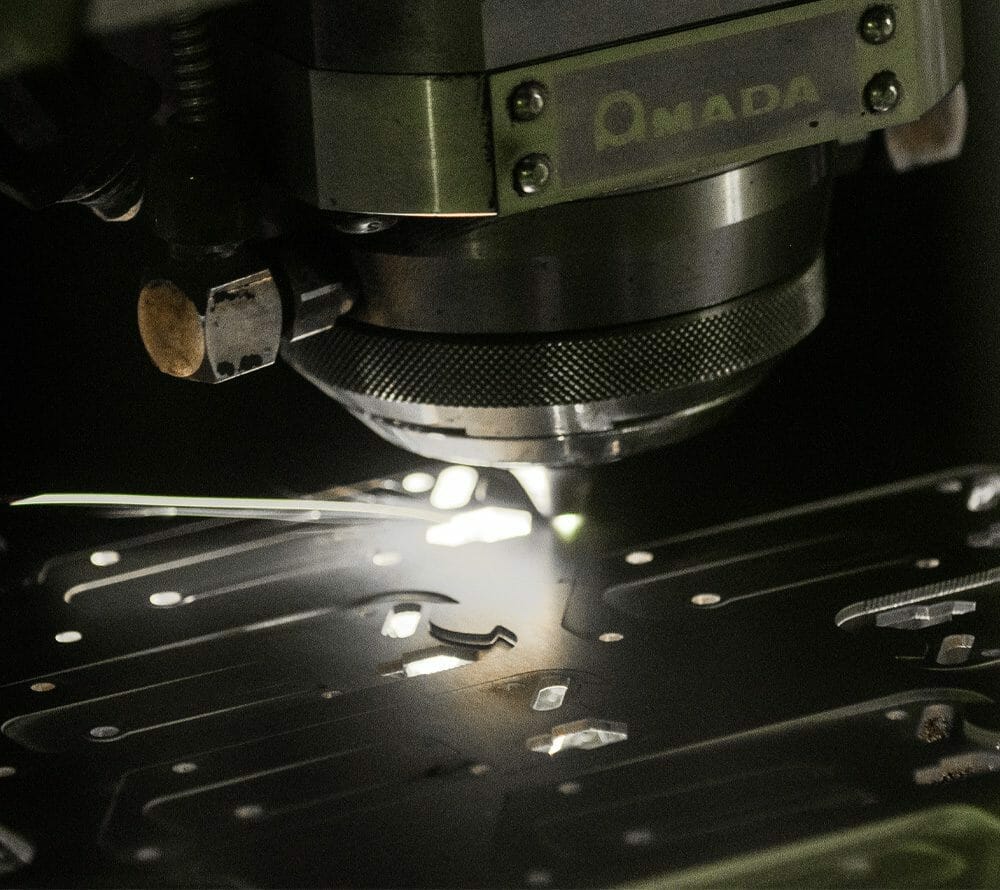

Laser cutting produces a sharp, accurate, and clean cut quality. SendCutSend utilizes multiple fiber lasers ranging from 4kW to 12kW to ensure that the cut and edge quality on your laser cut parts is unmatched. We are able to accurately and cleanly cut designs with very little dross and burr left behind because we’re putting as much power as possible behind our lasers.

With our high-powered lasers, we’re also able to cut down on the striations left behind on the edges of your parts. Striations can negatively impact the tolerances of laser cut parts and are more often found on thick materials cut with a lower power laser. The decreased edge quality from striations can also cause issues with weathering and oxidation, so by ensuring that the parts we laser cut don’t have noticeable striations, we’re able to help you keep your parts looking better for longer.

Clean edge quality is also more than a “nice to have” in the long list of requirements for a successful laser cut part. The better the cut quality is on a laser cut part, the easier it will be to process and finish with powder coating, paint, or anodizing. While we offer a deburring service for most of our materials, if you want to deburr and finish your parts yourself, it will be much easier because of the high quality cuts our laser provides.

Keeping Tight Tolerances With Inner Geometry

Although inner geometry is challenging with any subtractive manufacturing method, laser cutting is capable of keeping it tight and clean. Because laser cutting has a smaller kerf than many other machining methods, it’s better suited for cutting out geometry within the part that requires tight tolerances. SendCutSend is able to achieve even tighter tolerances with our unique processing and state-of-the-art fiber lasers which will hold +/-.005” tolerance on most laser cut materials.

In addition to our tight tolerances, our fiber laser beam diameter (kerf) is only .006”-.010” depending on your material. You do not need to make any adjustments to your design or file to compensate for the beam width because our automated system does it for you. Because of this, we’re able to cut complex designs and tight inner geometry without compromising the integrity of your original design.

Just keep in mind that while our lasers are capable of amazing things, they aren’t magic, and your designs still need to fit within all our geometry guidelines. Check out our laser cutting design guidelines for the full list of requirements, but here is our initial pre-flight checklist you’ll need to go over before uploading your design:

- File is a two-dimensional vector format file

- All holes and cutouts are at least 50% material thickness (no less than .063″ for waterjet cut parts)

- File is built at a 1:1 scale, preferably in inch or mm units

- All objects are on the same layer

- All stray points, duplicate lines, empty objects and text areas have been removed

- No shapes have open contours

- All shapes have been united, combined or merged

- All text has been converted to outlines or paths

- Cut-out text (reversed text) has bridges or has been stencilized

High Powered, High Speed

Here at SendCutSend, we’ve always been proud of the speed at which we’re able to process, machine, and ship your online orders. But the addition of multiple 12kw fiber lasers to our locations makes it even easier to laser cut your parts faster than just about anyone else. These lasers are 8 times faster than the average lower powered lasers, giving us the ability to cut parts with unmatched precision and speed.

As machining gets faster, your parts get more affordable. Long machining times means the laser is running for longer and your parts are taking up space inside of it, and both of these things increase the overall cost of the process. Since we’re able to machine parts quickly and process them efficiently, we’re also able to keep the cost for your individual parts low.

Affordability aside, who doesn’t love receiving parts within a handful of days of placing the order? We machine and process most standard parts within 2-4 business days of receiving your order, and shipping only takes 3-5 days for standard orders once they leave our facilities. (Keep in mind that post-processing such as deburring, tapping, bending, and powder coating will all add to the processing time. See our processing times for details..)

SendCutSend’s Laser Cutting Is Better Than Ever

We’ve added a lot of processes to our services over the years, but laser cutting remains the core of our business. We’ll never get tired of seeing your designs come to life in our lasers, and we’re continually innovating and improving on our processes to ensure that you’re getting the best possible end result.

To get started laser cutting with SendCutSend, make sure your file fits within our guidelines and then get an instant pricing today!