Getting the most out of your laser cut or waterjet cut order is a valuable skill when ordering machined parts online. Especially when you’re a business who needs to create 100k parts, efficiency and saving money are a big deal. Using a laser cutting company that can bulk cut parts is a start, but you can increase your efficiency in pricing by adjusting your designs long before they get to us.

Whether it’s for your business or a personal project, maximizing your budget allows you to design mind-blowing products and parts without breaking the bank. We’re going to show you how to design your parts for efficiency in pricing to do just that, with everything from materials to how to get a SendCutSend discount code.

Alternative Materials

Choosing the correct material for your project is one of the most important aspects of maximizing your budget. Everyone loves high strength 7075 aluminum or Grade 5 Titanium, but not every single project requires such high tensile strength or the price tag that comes with it. Many multi-purpose, generic parts with applications in everything from robotics to the medical field can be designed with a more cost effective alternative.

SendCutSend offers a range of high quality materials at a variety of price points. Some of our best and most affordable alternatives are:

Inner Geometry and File Setup

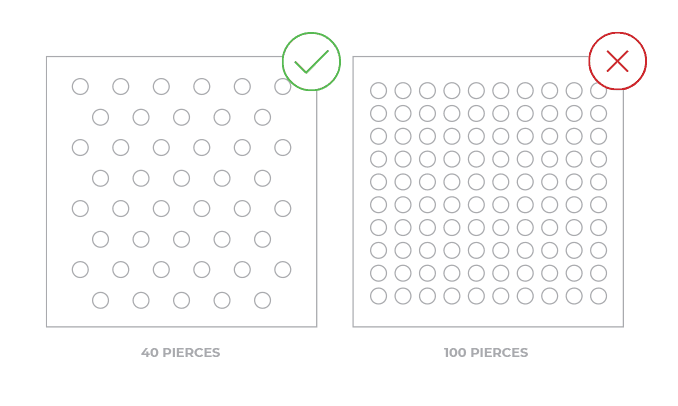

Another important part of designing parts for pricing efficiency is keeping the number of pierce points in the design low. The “pierce point” is where the laser enters or re-enters the material to cut out internal geometry. A cost-effective, simple design has few pierce points, minimizing the amount of separate pieces of geometry the laser has to cut out.

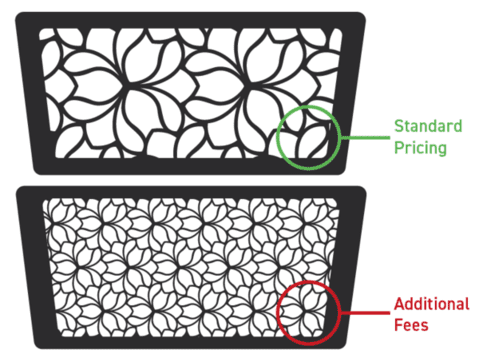

Ensuring that the designs of your inner geometry are simple can help keep costs low as well. The more time the laser has to spend cutting complicated designs, the higher the cost per part will be. This means complicated shapes and cutouts like perforated patterns, such as a speaker grille, intricate floral designs, and thin bridging will increase costs and the designs have a higher potential of burning out and getting lost in the machining process.

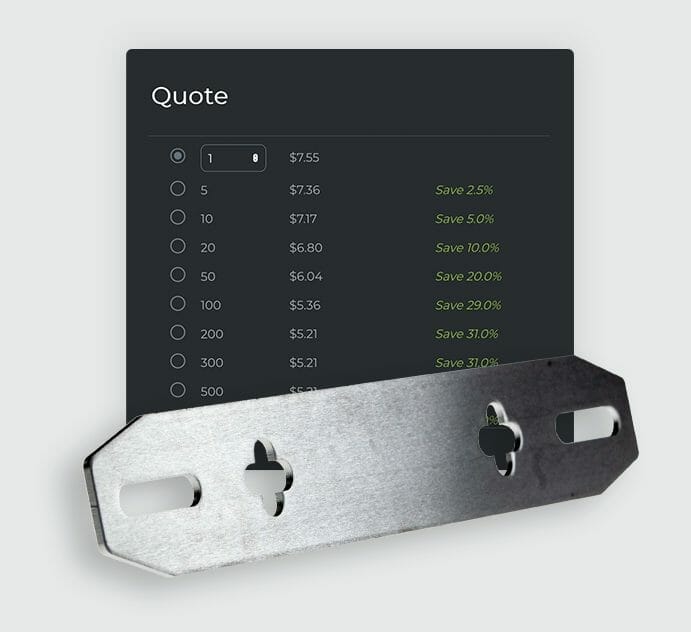

Part of keeping the file simple is making sure that your parts are not pre-nested. “Pre-nesting” is the act of putting multiple parts in one file. It may seem counterintuitive, but pre-nesting your parts like this will cost you more money than uploading one part per file. When you upload one part per file, you’ll be able to take advantage of our quantity discounts that start as soon as you order more than one of the same part. Ordering 50 of the same part can give you a 50% discount. This also allows us to nest your parts for the laser cutter in a way that minimizes material waste and directly saves you money on your order.

The best way to make sure your parts are designed for pricing efficiency and simplicity is to follow our design guidelines for each material (available on the individual material page) and machining process.

Exterior Geometry

Keeping the outer dimensions of your part small will help keep per part costs low. Large parts that require a lot of material and space are inherently more expensive, so we recommend keeping all your designs smaller than 28” on the largest dimension. The total material used in these large designs adds significantly to the area cost of the part, but they also take a longer time to machine than smaller, simpler parts. This increases the amount of time the laser or waterjet cutter spends on just one part, and longer machining times also increase the cost per part.

If you have a large part that needs to be of a certain size, such as a business sign, we recommend splitting the largest pieces into smaller parts and fixturing them together to achieve a larger size. Keep in mind this is our recommendation for pricing efficiency, but offer instant quoting on parts up to 44” in one axis if your design requires that sizing.

Outside of the material conservation benefits, a large order of the same small parts will once again allow you to take advantage of the quantity discounts that you wouldn’t get with one large part. These quantity discounts apply to parts in any of our many machining and post-processing services, like waterjet cutting, powder coating, and bending.

Getting a SendCutSend Discount Code

The last way to save money on your order is with a SendCutSend discount code. We send out discount codes to our mailing list for everything from holidays to adding new services, and they’ll knock a significant amount off your final order cost. These discount codes are exclusive to our mailing list members, however, so be sure to join the mailing list to be first in line for the best SendCutSend discounts.

We want to see your designs, projects, and businesses succeed with SendCutSend, so we’ll make sure you’re able to get the most out of your order. Following these recommendations and making sure that your parts fit within our guidelines will help you maximize your budget for a successful project.

Once you’re ready, just upload your files to our instant pricing tool. Most parts ship within 2-4 business days!