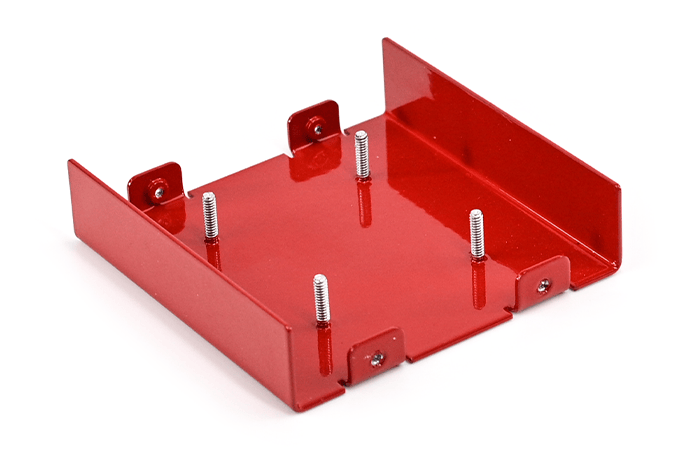

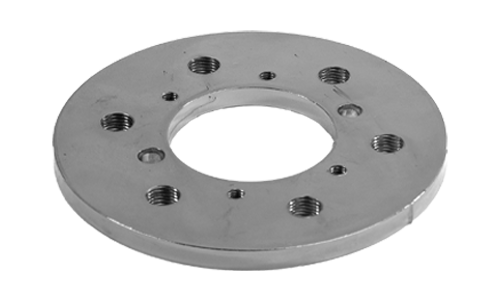

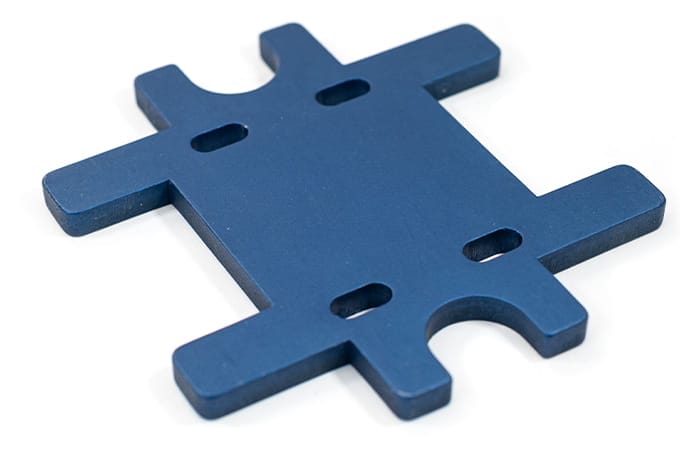

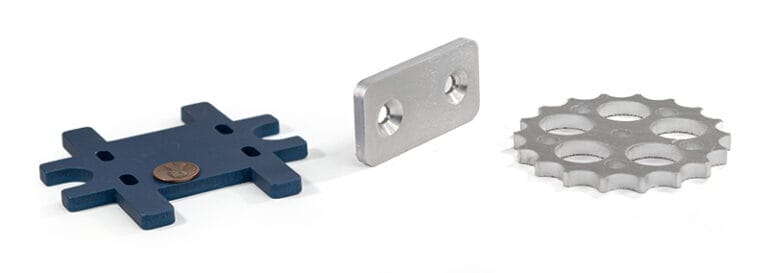

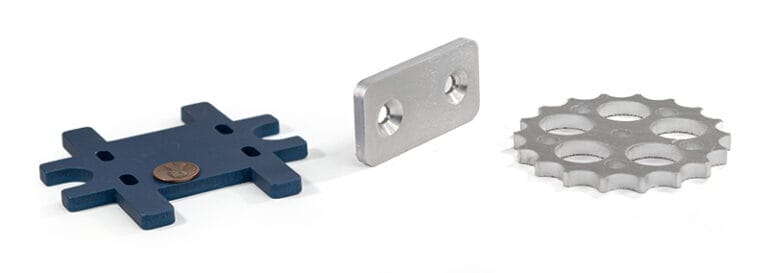

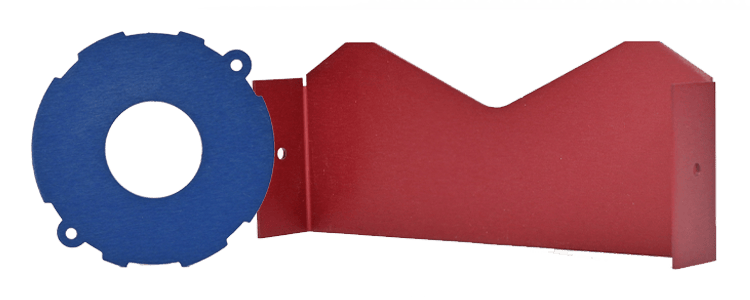

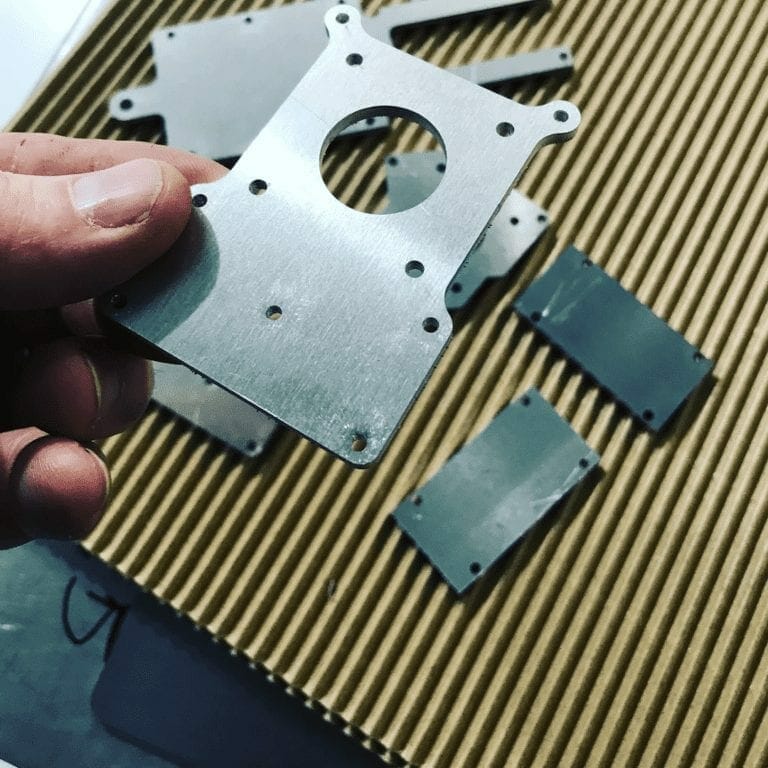

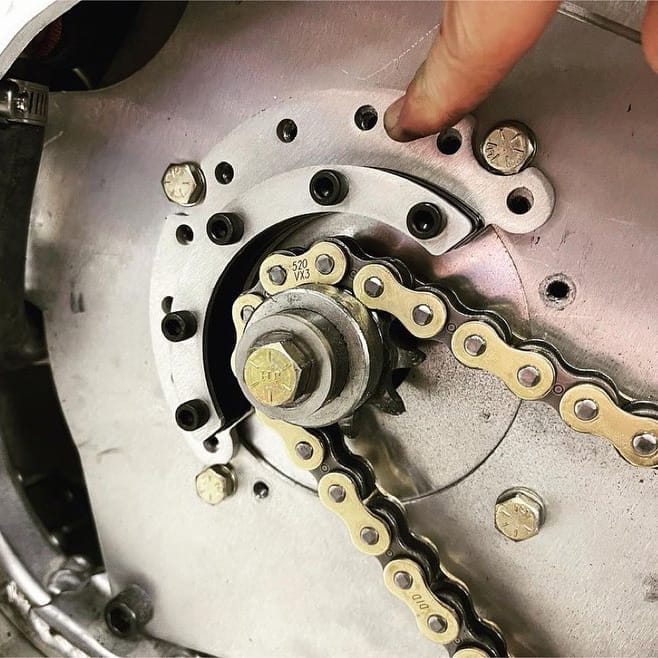

Laser cut 5052 aluminum is one of our most popular metals. Used in a wide variety of applications including aerospace, automotive, and robotics, 5052 H32 aluminum is an excellent mix of high performance and affordability.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 56″

.040″ (1.02mm)

.063″ (1.60mm)

.080″ (2.03mm)

.090″ (2.29mm)

.100″ (2.54mm)

.125″ (3.18mm)

.187″ (4.75mm)

.250″ (6.35mm)

.375″ (9.53mm)

.500″ (12.7mm)

5052 H32 aluminum is strong, inexpensive, and lightweight. Whether you’re welding, machining, or bending, 5052 aluminum is going to be the go-to material for those projects that need excellent all-around material properties. Our laser cut 5052 aluminum is exceptionally lightweight and strong, making it perfect for projects where overall load is a concern.

With high relative ultimate strength (and fatigue strength), 5052 aluminum has a number of practical usages. It is non-heat treatable, which means that it is cold-worked to achieve its moderate-to-high strength properties. For greater strength, check out our 6061 series aluminum.

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

SendCutSend offers 5052 H32 Aluminum in ten thickness options: .040″ (1.02mm), .063″ (1.60mm), .080″ (2.03mm), .090″ (2.29mm), .100″ (2.54mm), .125″ (3.18mm), .187″ (4.75mm), .250″ (6.35mm), .375″(9.5mm), .500″ (12.7mm).

5052 H32 Aluminum is available at SendCutSend with a range of thicknesses and part sizes. Instant quotes are possible for dimensions between .25″ x .375″ and 30″ x 44″, while custom quoting extends the maximum size to 30″ x 56″.

You can add the following services to your 5052 H32 Aluminum parts: Anodizing, Bending, Deburring, Countersinking, Deburring, Engraving, Dimple Forming, Hardware Insertion, Powder Coating, Tapping, and Tumbling