Our online laser cutting services are trusted by businesses, manufacturers, engineers, and makers in a variety of different industries from all over the country. Why?

- No worries about kerf.

- No need to pre-nest.

- No hidden fees.

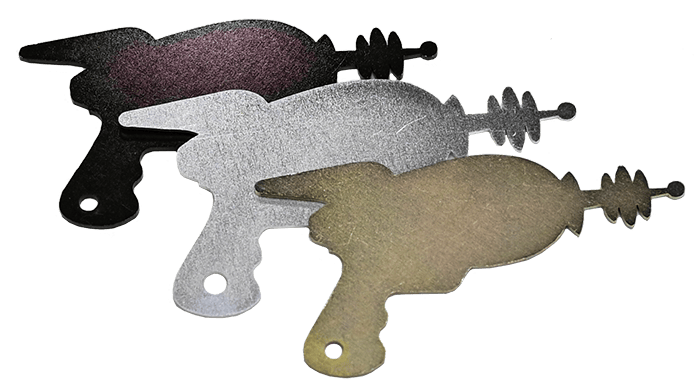

With 150+ materials available for laser cutting, SendCutSend is consistently ranked as one of the fastest and most efficient online laser cutting services in the industry today. We know that the quality of our parts is unmatched, but we’ll let the work speak for itself—

“They are the quickest, best quality, and almost unbelievably, the most affordable company I’ve had the pleasure to do business with. We were able to crowdfund over $225,000 for our first multi-tool thanks to SendCutSend!” — Michael O’Donnell, GOAT Tools

Whether you’re looking for metal laser cutting services, composite laser cutting, plastic laser cutting, or laser cutting services for wood or boards, we’ve got what you need to get your project over the line (and can do it faster than anyone else). Looking for a material that we don’t carry? You can request a new material or thickness. Our team is always looking for new materials to stock, and when it comes to ensuring your custom parts are exactly what you are looking for, we’ll do everything we can to guarantee you’re 100% satisfied (or we’ll give you your money back).

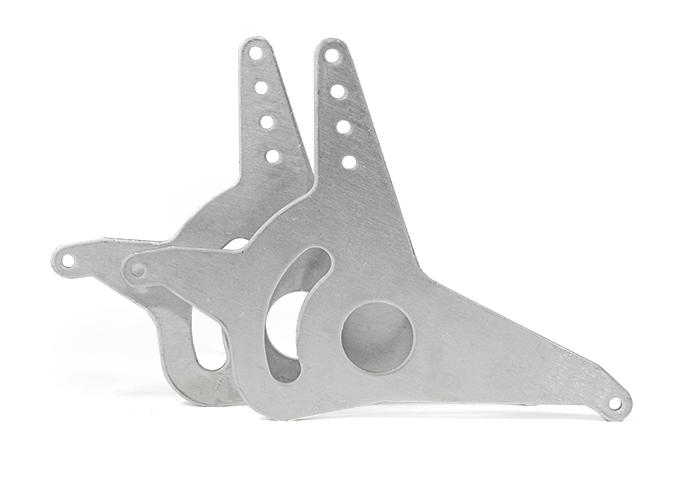

Custom Laser Cutting Metal With Unmatched Precision

SendCutSend only uses the highest quality materials when it comes to laser cutting metal and sheet metal laser cutting services. Whether you’re prototyping for your business or building a car in your garage with laser cut parts, making the right choice when it comes to your material can make or break your project.

From popular metals like Stainless Steel, Copper, and Aluminum to Brass and Mild Steel, the best type of metal (or sheet metal) will depend on your project, but with the many considerations you already have to take into account—weight, aesthetic, durability, strength—quality should never be one of them. Depending on the application, SendCutSend will guide you through what metals work best for your project, what type of tolerances you’ll need to consider, and how you can further improve the precision of your parts with finishing processes that are unique to your material and application.

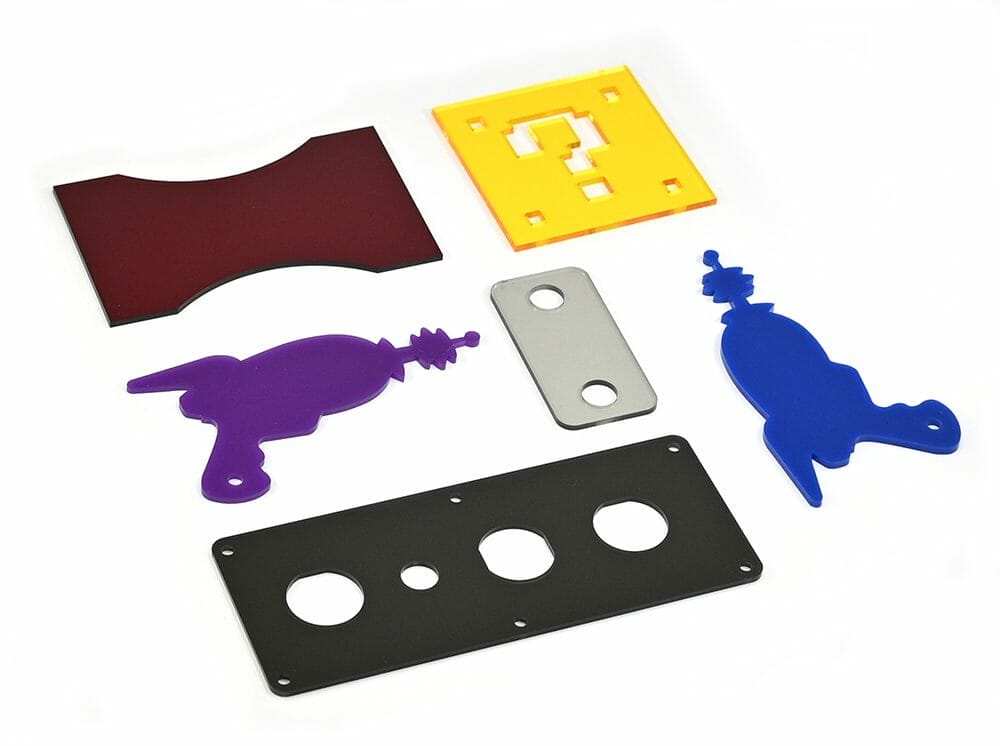

Cutting ABS, Acrylic, Delrin, HDPE, Polycarbonate, & UHMW Sheet Plastics

SendCutSend started out as a metal manufacturing company, sure, but when our customers asked for more affordable materials that were easier to machine, could save space, and were more lightweight, we delivered. Sheet plastics consisting of ABS, Acrylic, Delrin, HDPE, Polycarbonate, and UHMW give projects a wider range of attributes and abilities that metal simply can’t match.

When it comes to laser cutting sheet plastic, SendCutSend can help you understand what purpose each of our sheet plastics serve, their pros and cons, price points, common applications, and more so you can get the custom laser cut plastic parts you need, at a fraction of the cost.

Waterjet Cutting Carbon Fiber — Choosing the Right Composite Material for Your Project

Let’s talk about the black sheep of the laser cutting materials world. Composite materials aren’t really metal or plastic, and each and every one of them is different from the other. SendCutSend offers ACM (Aluminum Composite Material), Carbon Fiber, Cork (Gasket Grade), G10/FR-4, and Le Phenolic Linen (Micarta) to those who have browsed countless material catalogs and still can’t quite find the right material to fit their application.

One thing to keep in mind when it comes to laser cutting carbon fiber, or any composite material for that matter, is that the manufacturing process is quite different from the plastic or metal laser cutting process. For example, ACM uses the CNC Machine, Cork is laser cut, and the rest of the materials mentioned above are cut on a Waterjet—but don’t stress. SendCutSend will show you how to select the right composite material for your project, can help you compare costs, walk you through the manufacturing process, and provide you with a breakdown of all the different material properties and restrictions each composite has.

Additional Laser Cutting Services to Improve Your Parts

Clean edges, tight tolerances, and beautifully-crafted finishes are just the beginning. SendCutSend offers a full line of services that will bring your project (and your parts) to life. With custom parts starting at just $1, we offer quantity discounts up to 70% whether you order 1 part or 1,000,000+.

From CNC Routing and Waterjet Cutting to Anodizing, Bending, Countersinking, Plating, Powder Coating, Tapping, Deburring, and Hardware Installation, you can rest assured that your laser cut parts will be high-quality (did we mention our linear deburring process is included at no cost, too?). We want you to have the best-looking parts when they arrive at your door, and to do that, accuracy will always be our top priority.

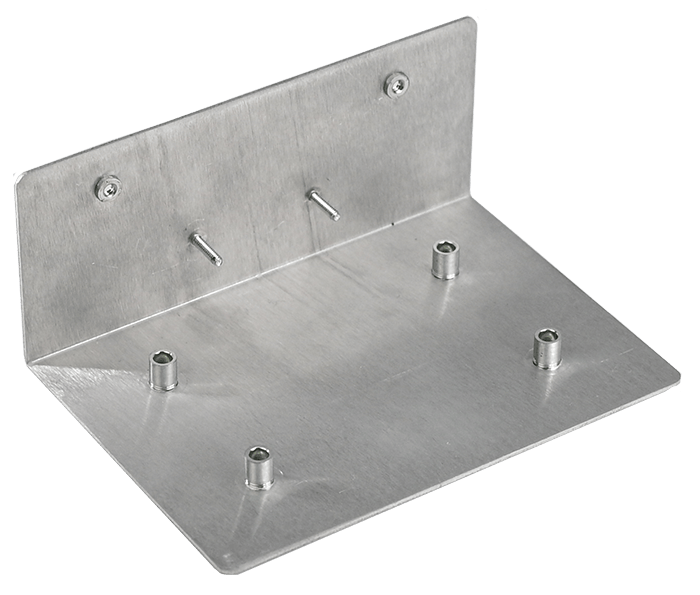

Hardware Installation Services

Let us help you solve your design problems. Hardware installation at the fabrication stage simplifies projects and improves performance. Hardware provides options when there is little to no access to the backside of a part after installation or in place of tapping in thin or soft materials. At SendCutSend, we proudly use PEM fasteners, the industry standard for nuts, studs, and stand-offs. And thanks to their lightweight design and strength, fastener insertion on your custom metal parts is not only quick but also cost-effective.

Whether you need Tapping Services to form threads in the holes of a part to add hardware later, or want to use our Countersinking Services to make your hardware heads sit flush against the surface of your parts, our team of highly-trained machinists (and state-of-the-art manufacturing technologies) have made it easier than ever to design, order, and receive precision laser cut parts for a variety of different projects and applications anywhere in the U.S. (and Canada).

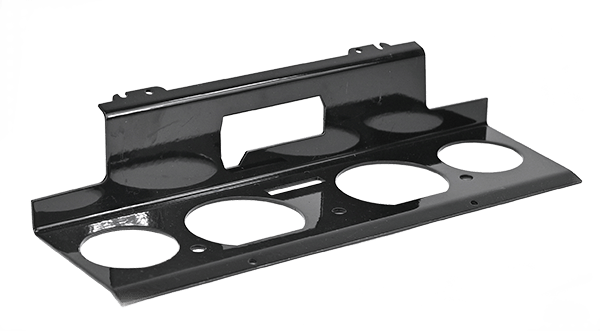

Bending & Forming Services

Ready to make your 2D metal project into a 3D part? CNC Bending is where you should start. SendCutSend bends laser cut parts to your exact specifications within one degree of accuracy or better to ensure your final product fits within tight tolerances—making a difficult process way easier than it used to be.

Wait, Let Us Finish

Choosing the right finish for your laser-cut parts will make them more durable and increase their lifetime. With Anodizing and Plating Services that increase your parts’ resistance to corrosion and wear, and Powder Coating Services that give your laser and waterjet cut parts a bold, long-lasting finish (while increasing their resistance to damage), SendCutSend can help you get your parts laser cut and finished, all in one place.

SendCutSend’s Tips & Tricks for Custom Laser Cutting

When it comes to laser cutting services, our innovative processes continue to set the industry standard. We’re here to help connect you with the right resources so you can stay-up-to-date as we continue to evolve our applications in this ever-changing, laser-cut-part-manufacturing, landscape.

From helpful guidelines and best practices for all of our laser cutting services to the latest news, articles, and even project inspiration, SendCutSend offers our community tutorials, product ideas, insight into processes, and so much more.

The Benefits of Using SendCutSend’s Laser Cutting Services

Online laser cutting services should be fast, efficient, and high-quality. It’s that simple. It shouldn’t take weeks to get your parts (and a ton of money to produce them). That’s why at SendCutSend, we like to cut to the chase:

- Our online laser cutting services start at $1 ($39 minimum per order).

- Production time for standard orders is 2-4 business days (or less).

- We offer quantity discounts up to 70% off (with no minimum quantities required).

All you have to do is upload your CAD file, get a real (and instant) quote—which includes the price of materials, cutting, and deburring—and then wait a few days for us to ship your order. It doesn’t get easier than that.

Getting Started With SendCutSend

Starting your next project with SendCutSend will change the way you work. Get a quote through our online quote system for fast and accurate pricing on materials, processes, and services. We can’t wait to help you bring your ideas to life.

Are you a business? Contact us to learn how SendCutSend can help improve your production processes. Ready to order but need Net 30 invoicing? No problem. Fill out a credit application here.