Whether you’re a hobbyist or a professional engineer, understanding how costs are calculated and what factors impact them is key to making smart decisions for your projects. In this post, we’ll break down the essential elements that go into determining the price of metal parts and how you can save money without compromising on quality.

Key Takeaways:

- The price of different materials, including aluminum, stainless steel, and mild steel, and how surprisingly similar they can be.

- Why material properties matter for long-term durability and project requirements.

- How quantity affects pricing, and the significant discounts available for bulk orders.

- The importance of considering finishing processes, like powder coating, in your total cost.

- Understanding that shipping is free and factored into the price, ensuring no surprise fees.

How much do custom sheet metal parts really cost? Video Guide

What determines the cost of custom sheet metal parts?

The cost of your metal parts with SendCutSend is influenced by several factors, ranging from the material you choose to the complexity of your part’s design. In this blog, we focus on three main materials: 5052 aluminum, HRPO (Hot Rolled Pickled and Oiled mild steel), and 304 stainless steel. Each has different properties, but interestingly, the pricing between them is often closer than you’d expect.

So, why does this happen? One major reason is the sheer volume of material purchased by companies like SendCutSend. For us, buying thousands of tons of material at a time allows us to pass on savings to the customer. So while your local shop might price aluminum higher, larger suppliers may offer more competitive prices.

Material grades and their impact on price

Another factor is how different grades of aluminum can affect the final price. For instance, 6061 aluminum is typically more expensive than 5052 aluminum because it offers added strength. When planning your project, it’s important to ask yourself whether you need the extra strength. If not, sticking to the lower-cost material can save you money without sacrificing performance.

Stainless Steel – more expensive but worth it?

When talking about 304 stainless steel, it’s more expensive upfront compared to mild steel or aluminum. In the above example provided, parts in stainless steel were priced at $12 each, while the same parts in aluminum or mild steel were around $8.50. But stainless steel’s durability, particularly in outdoor or corrosive environments, can save you from needing extra finishes or replacements later on.

For projects like outdoor barbecues or countertop coverings, stainless steel’s rust-resistant properties make it a solid choice that could save you from the hassle of annual maintenance or the added cost of protective coatings.

Geometry and cutting time – design complexity matters

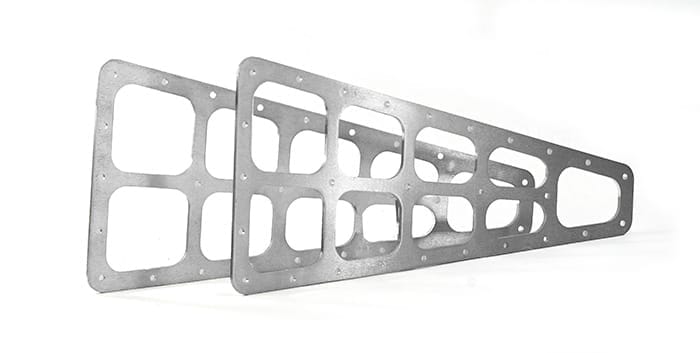

The more complex your design, the longer it takes to cut and machine, which increases costs. The pictured part, a thinner, more intricate part made from 5052 aluminum was priced at $27 each due to its complex geometry, compared to simpler designs that cost less to produce. If you’re working on a design with many fine details, keep in mind that cutting time will increase the price.

Finishing processes: to powder coat or not?

Powder coating is another factor that influences pricing. While a raw aluminum part costs $27, the same part with a powder coat finish costs $43. Though this may seem like a significant price jump, powder coating offers better long-term durability and a cleaner finish, making it an attractive option for customer-facing products.

Quantity discounts on custom sheet metal parts

Perhaps one of the most important tips for saving money is quantity on pricing. The first part of a production run is always the most expensive due to setup and handling. For example, a small zinc-plated G90 steel part costs about $29 when ordering just one. But if you order ten, the price drops to just $3 per part. This dramatic price reduction is thanks to the efficiencies gained in producing multiple units.

Most materials see discounts starting with the second part and continuing all the way to large bulk orders, where you could see up to an 86% discount in some cases.

Size and waste reduction for affordable sheet metal parts

Another way to save money is by minimizing the size of your parts. Larger parts use more material and take more handling time, naturally increasing costs. However, waste reduction is our responsibility, so you don’t need to worry about scrap material when ordering.

Free shipping on metal parts and transparent pricing

Lastly, one of the most customer-friendly aspects of working with SendCutSend is that shipping is free anywhere in the USA on orders over $39 on orders over $39. The price you see at checkout is the price you pay, with no hidden fees added later. Whether you’re shipping a single part or a bulk order, it will arrive at your door without any surprises.

Finding Affordable Custom Sheet Metal Parts

When it comes to custom metal parts, there’s more to pricing than just the cost of raw materials. Factors like material selection, design complexity, finishing, and quantity all play a significant role in determining the final price. By understanding these variables, you can make smarter choices for your projects and save money in the long run.