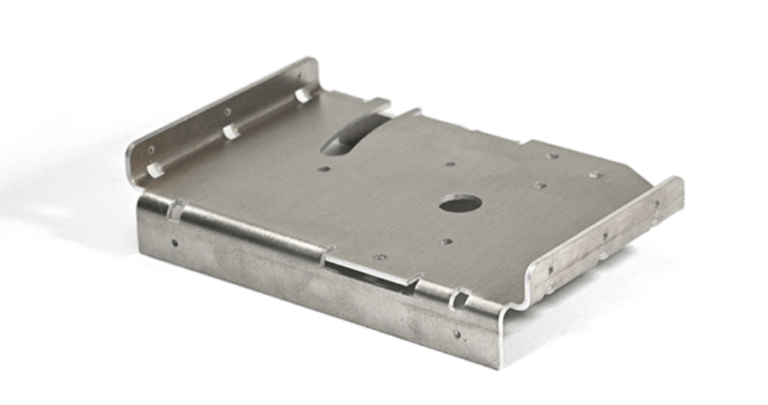

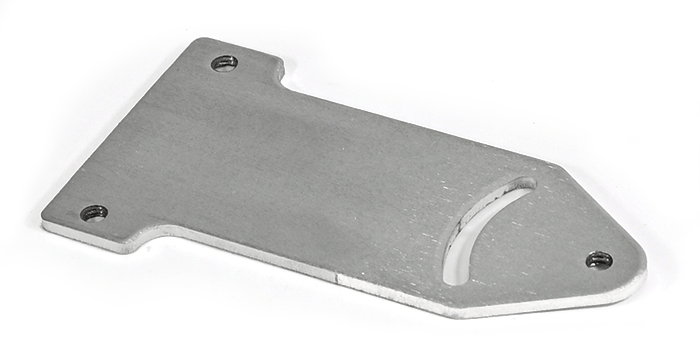

Laser cut stainless steel (304 series) is our favorite metal for many projects, including industrial robotics, decorative applications, and automation machinery. It’s durable, strong, and easy to work with. If you have a project that needs to stand the test of time, stainless steel is a great choice.

Instant quote

A: .25″ x .375″

B: 30″ x 44″

Custom quote

C: 30″ x 56″

.030″ (0.76mm)

.048″ (1.22mm)

.060″ (1.52mm)

.074″ (1.88mm)

.100″ (2.54mm)

.125″ (3.18mm)

.187″ (4.75mm)

.250″ (6.35mm)

.375″ (9.53mm)

.500″ (12.7mm)

Thicknesses greater than .125″ will have a factory #1 mill finish. When not deburred, the appearance will be dull with visible mill scaling.

Weldable, formable, and easy to work with, 304 stainless is our first choice for projects that require massive strength and durability.

Laser cut 304 stainless steel is oxidation resistant, making it easy to sanitize and maintain. This particular feature makes 304 stainless steel the go-to grade for many food service applications, from countertops to cookware.

Fusion welding performance for 304 stainless steel is excellent both with and without fillers so it’s a strong choice across projects that require welding. Heavily welded sections sometimes require additional treatments, such as annealing, but generally the material is simple to weld.

Ultimately, you can count on SendCutSend’s 304 stainless steel laser cutting services to meet your project’s needs and provide solid parts made to your specifications.

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

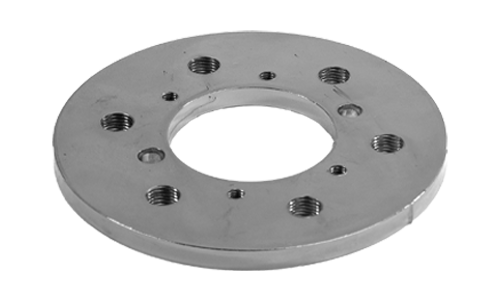

This material is available in ten thickness options: .030″ (0.76mm), .048″ (1.22mm), .060″ (1.52mm), .074″ (1.88mm), .100″ (2.54mm), .125″ (3.18mm), .187″ (4.75mm), .250″ (6.35mm), .375″(9.53mm), .500″ (12.7mm).

SendCutSend cuts 304 Stainless Steel in a broad range of sizes and thicknesses. Instant quoting is available for parts as small as .25″ x .375″ and as large as 30″ x 44″. Larger parts, up to 30″ x 56″, can be ordered through a custom quote.

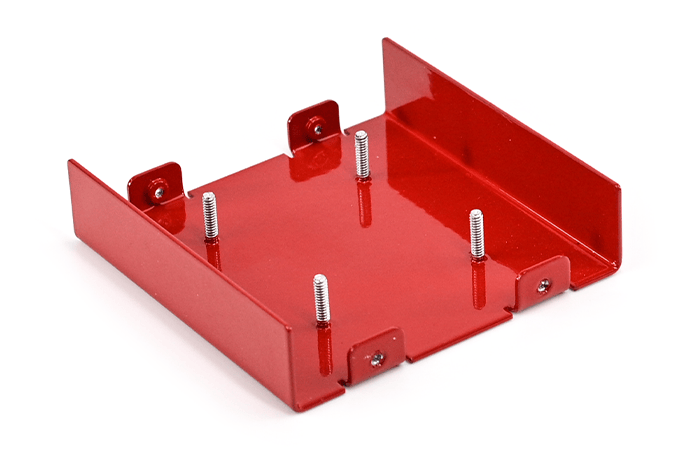

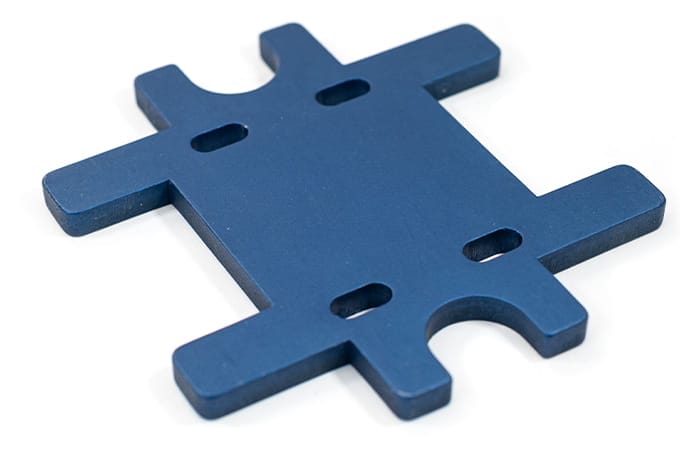

You can add the following services to your 304 Stainless Steel parts:

Bending, Deburring, Dimple Forming, Hardware Insertion, Powder Coating, Tapping, and Tumbling