The automotive world is full of unique fasteners, developed for special applications. Tapping into this library of hardware can be a great way to elevate your projects, whether they are auto related or not. Because these specialty fasteners are less common than standard fasteners, many people aren’t familiar with them (or even realize they exist).

In this article we’re going to cover some of the fasteners that come from the automotive industry and how you might be able to utilize them in your projects.

Types of Automotive Fasteners for Your Parts

The auto industry manufactures millions of cars each year, which allows them to develop fasteners that aren’t common in other industries. Having a familiarity with some of these specialty pieces can give you additional tools when designing your own projects. Mostly used to secure sheet metal and plastic panels, a lot of these fasteners are meant to make assembly more efficient, where both sides of the joint aren’t accessible.

Let’s look at some of these in more detail.

- Bolts and Screws

Bolts and screws are used in nearly all industries to join components together. Standard bolts and screws come in standard sizes, while automotive fasteners have a lot in common with those that follow standards (threads diameters and pitches are typically standard), they may have unique head styles, materials, finishes, lengths or other special features.

Some of those special features may include low profile heads for component or tool clearance. They may have built-in captive washers to better distribute the load across the panel. Thread cutting screws can be used in soft materials like plastics and composites.

- Nuts

Automotive nuts come in a wide range of styles. The different styles may be called by different names, but they often function similarly.

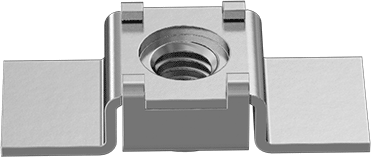

Captive nuts, cage nuts, spring nuts, clip-on nuts all hold a female thread in position while still allowing it to float slightly. The purpose of this is to allow for two components that may not fit perfectly (as in the mating holes/features may not align closely enough to get a fastener through) to allow for the misalignment and bolt together. This is common in formed sheet metal parts.

Sometimes they snap into a hole, whether square or round.

Sometimes they slip over the edge of a panel and pop into an oversized nearby hole.

The cage around the nut may even be welded to the panel.

- Self-Clinching Fasteners

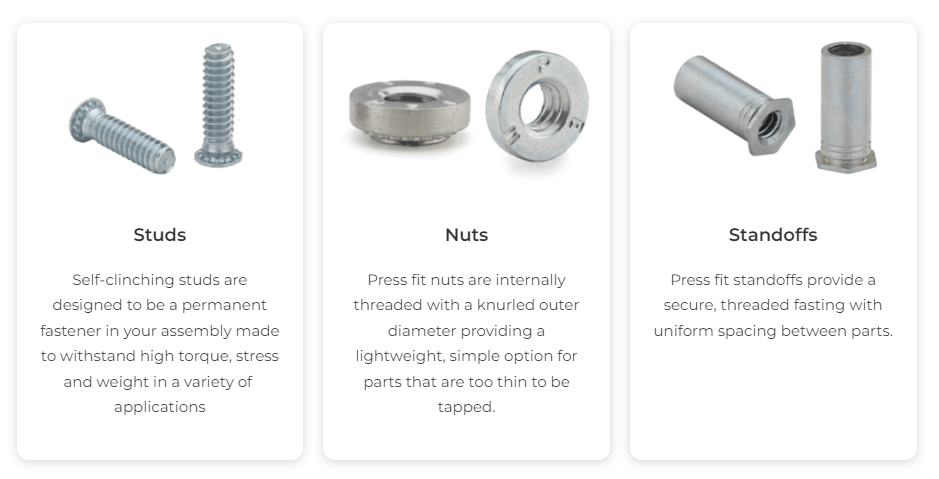

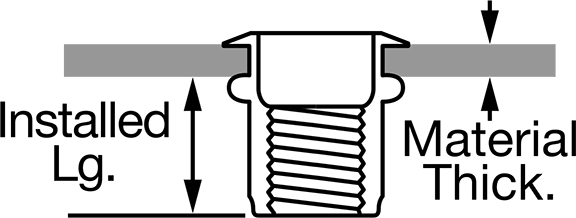

Self-clinching fasteners, sometimes called by the brand name PEM fasteners, are another type of threaded fastener used often in thinner sheet metal construction. They press into a precisely cut hole and use serrations to provide a strong grip on the panel. Nuts, studs and standoffs are typical styles for self-clinching hardware.

These are useful when assembly access to both sides of a joint are difficult for a standard nut and bolt, when lower profile hardware is beneficial, or when the material is too thin for other types of fasteners. The standoff style does a great job of providing threaded features and a clearance between components, all in one piece of hardware.

SendCutSend now carries self-clinching fasteners and can install them into your parts for you!

- Riveting Fasteners

You may be familiar with rivets, in either the old school peened variety or the more modern pop-rivet style. There are however other styles of rivets that include threaded features. Rivet nuts and studs all function similarly to pop-rivets, where they are inserted into a hole from one side and a special tool is used to deform the rivet clamping it onto the panel. This leaves a rigidly attached fastener to secure other components using a standard bolt or nut

- Clamps and Retainers

Not all fasteners use threads, sometimes a retainer holds two components together by snapping into a hole in one and pulling the other tight using a head larger than the hole. These are often plastic or spring steel since they rely on being flexible to hold securely. You may see these called Christmas tree retainers because of their shape.

Some of these are simple one piece components. These will quickly wear and become loose if you try to reuse them too many times. An alternative may be a two-piece style that can be assembled and disassembled easier.

Similarly, a clamp or retainer may have a special feature on the head to clamp other parts such as wiring or hoses.

- Springs

Springs aren’t used to fasten components together, but they are used to control the relative motion of components. A throttle return spring keeps your throttle pedal from staying on the floor, a door assist spring helps take the weight off of a door making it easier to move. Springs may also be useful for taking the slop out of joined components. Often two components need to be bolted together loosely so they can still move freely, but that looseness can cause rattling. A simple spring can still allow free movement, but apply slight pressure keeping the joint from rattling.

The springs you’re most likely familiar with are coil springs. They come in both compression and tension varieties. You can get flat ends, ends with hooks, loops, etc.

You can also find torsion springs, meant to apply a rotational force around some axis. Torsion springs can be packaged tightly around a pivot keeping the mechanism compact.

A spring washer (not to be confused with a split washer), also known as wave washers or a Belleville washer is another common type of spring. Wave springs can be stacked to increase distance or force. They are great for applying a slight preload to bearings or other mechanisms.

Sometimes a simple piece of spring steel cut to the right shape can be the perfect fit for your custom design.

- Bushings

Similar to springs, bushings aren’t necessarily used to fasten components together, but they are useful between moving components. They’re job is to both provide a smooth friction surface for the parts to slide against and to be a replaceable wear surface. They also provide the benefit of creating a slight gap between moving components. This is especially useful for painted or powder coated parts that would otherwise have their coatings scraped away the first time the mechanism moved. Plenty of mechanisms are built without bushings, but if you want to take your designs to the next level, adding bushings is a great step.

You can buy bushings in common sizes or you can have custom sizes cut from an appropriate material like bronze, brass, copper, steel, aluminum, Delrin, UHMW, HDPE, etc.

What Automotive Fasteners Should You Use and When?

If you’re making custom car parts, automotive fasteners are an easy choice. But automotive related parts don’t have to be the only time to look at automotive fasteners. Their unique capabilities can help make any project easier, faster and less expensive to assemble, function better or simply look a little more professional.

We’d recommend reviewing the different types of automotive fasteners that are available (there are more than just what we’ve shown here) to see if they offer any features that might be useful in your project. Sometimes a standard fastener is a better choice, but sometimes a specialty fastener can push your design a little further, saving time and money.

Tips for Automotive Fasteners

With any threaded fasteners, be careful not to over tighten them. If you know the grade or class you can look up (or calculate) an appropriate torque value for tightening. If you don’t know the material strength, it’s safer to treat the fastener as if it were a lower strength material.

Plastic fasteners are meant for lighter duty applications than steel fasteners. Take care when using them that they are strong enough for what you need them to do. Sometimes all it takes is increasing the quantity of plastic fasteners to provide plenty of strength, but sometimes they’re not right for the job. They can also wear faster than steel parts. This may not be an issue for parts that get assembled once, but for parts that come apart frequently they could quickly start to show signs of wear.

All fasteners can loosen over time. This happens faster with high loads or vibration. With threaded fasteners you can apply a thread locking compound like Loctite to prevent them coming loose. You can also use self locking fasteners like nylon lock nuts. In safety critical applications, be sure to check fasteners for tightness regularly. Auto manufacturers will often mark the ends of threaded fasteners with a marking paint after they’ve been torqued. Following a practice like this can also help to give a quick visual indication if a nut or bolt has started to back off.

Where Can You Find Automotive Fasteners?

While most big box stores carry standard fasteners, they don’t always carry automotive-type fasteners. But don’t worry, they’re still fairly easy to find if you know where to look. Sometimes just knowing what they might be called is the hardest part. If you’re not familiar with them you may not think to search “Christmas Tree Fastener” or “Wave Spring”. Here are a few great sources for automotive fasteners:

- McMaster-Carr

- Fastenal

- Auto Parts Suppliers (AutoZone, Advance Auto Parts, O’Reilly, NAPA, etc.)

When it comes to self-clinching fasteners, SendCutSend offers these installed into your custom laser cut parts as a service. Check out the catalog for all the available types and sizes.

Simplifying Your Projects and Improving Performance at Fabrication

There are a hundred different ways to assemble your parts. Being more familiar with what options for fasteners are out there, can make it easier to select the best ones for your projects. Be sure to understand how each works to ensure adequate holding strength and longevity.

You’ll want to use the correct size holes (round or square) for the fasteners you choose. SendCutSend can precisely and accurately cut whatever you need. We can even install PEM fasteners into your parts for you. Just select the desired options when ordering and your parts will show up with all the correct hardware installed.Whatever your project, we hope this article gave you some useful info to make it even better. SendCutSend is here to help with quick, quality parts shipped right to your door. Check out all the services we offer to see what SendCutSend can do for your next project.