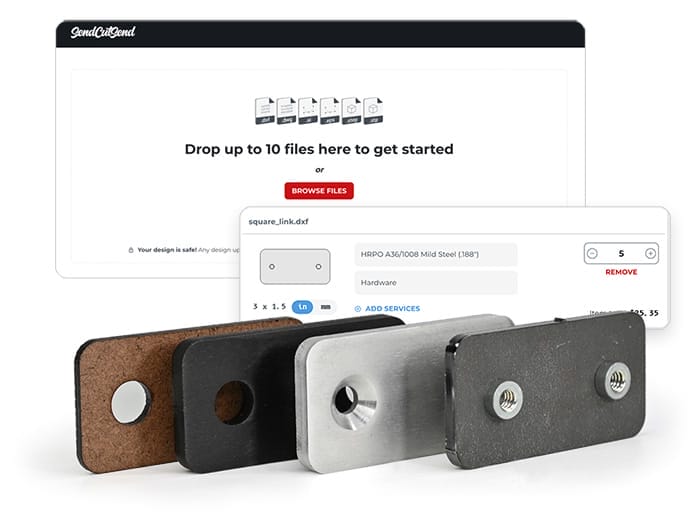

Cut down on time and cost with fast and precise laser cutting. SendCutSend allows for rapid prototyping, quick turnaround times, and bulk ordering. Our laser and waterjet cutting services are designed for everything from ideating to testing.

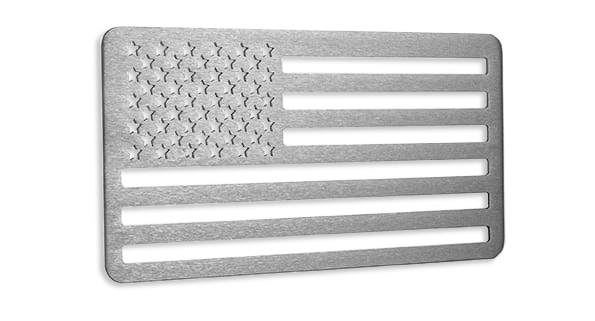

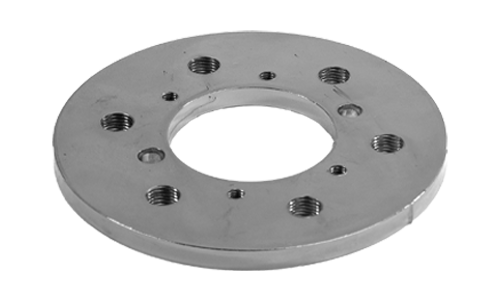

Choose from more than 165+ materials including metals, composites, plastics, wood and boards. See a comprehensive material and thickness chart here or view our metal selection guide for usage suggestions.

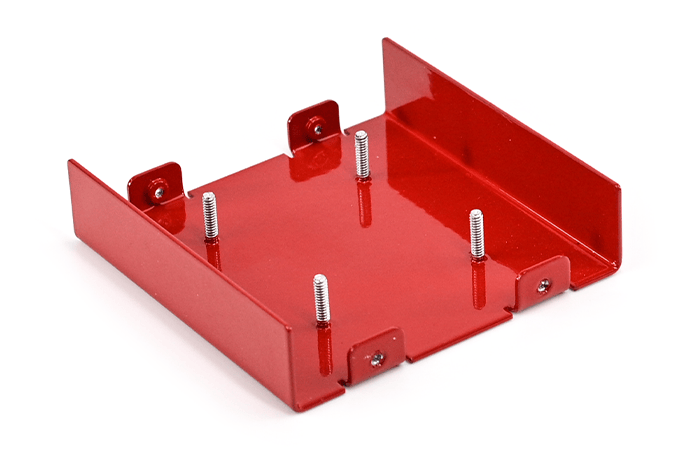

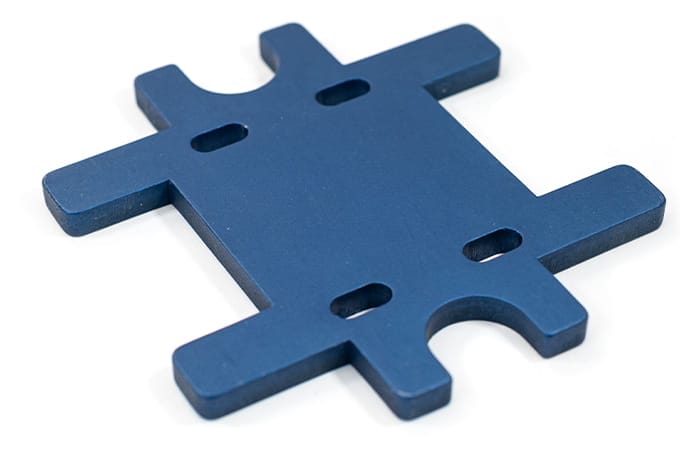

SendCutSend’s laser and waterjet cutting services provide quick turnaround for prototypes and parts for robotics, drones, and other projects.

We offer a full range of services to cover your project needs

Do you have unique needs or parts requirements? Get a custom quote.

You’ll never have to worry about long lead times, shipping costs or questionable customer support. All orders are produced in-house, in the USA with two locations to serve you in order to deliver the best quality, fastest speeds and lowest cost possible. We proudly ship anywhere in the USA and Canada.