We offer you A36, 1008, and A1018 carbon steel (mild steel) in three surface finishes: Cold Rolled Carbon Steel (1008), Hot Rolled Carbon Steel (A36), and Hot Rolled Pickled and Oiled Carbon Steel (A36/A1018).

Mild steel is a type of low-carbon steel that posesses a relatively low level of carbon content. This makes it malleable, ductile, and easy to weld. Our mild steel is the go-to choice for fabricators, welders, machinists, prototypers, and anyone else who needs a strong, reliable part that is easy to work with.

With our hot and cold rolled mild steel offerings, it can be challenging to know which best suits your current project, so we’re going to help clear that up for you. If you have any more questions that weren’t covered here, reach out anytime and our applications engineers will get back to you.

Our cold-rolled carbon steel is our customers’ favorite material to work with. Cold-rolled is basically just hot-rolled steel with additional processing. Those additional processes give it a cleaner edge, better surface quality, and more exact dimensions. Cold-rolled has exceptional refinement and tends to be a little stronger and harder than hot-rolled. For these reasons, cold-rolled is better suited for bending and fabrication.

Our hot rolled carbon steel is commercial mild steel, found in most industries as it offers good weldability and machinability. It’s sturdy and easy to work with. It has a scaled surface finish from the cooling process and as a result, it is free of internal stresses sometimes associated with further processing. Hot rolled steel can be used in bending but is more prone to cracking.

HRP&O steel is much smoother and easier to finish than the cheaper “mill finished hot-roll” that most steel centers sell. HRP&O is just hot-rolled steel that is subjected to an acid bath in order to remove scale mill. Then it has some dry oil applied to prevent rusting. Overall, it has a nicer finish.

Recognized for its cost-effectiveness, strength, and versatile nature, mild steel plays a pivotal role in a myriad of applications across different industries. Its widespread usage stems from its malleability and weldability, making it a favored material for fabricators and manufacturers. From providing the structural backbone in construction to forming the basis for automotive components, mild steel finds its place in an extensive array of products and structures.

We source this high-demand metal through trustworthy suppliers with verifiable industry credentials so you don’t have to worry about it. You’ll know that our 5052 aluminum sheets are ready to be transformed into your greatest ideas.

Material certifications (PDF) are available below.

5052 Aluminum .040″

5052 Aluminun .063″

5052 Aluminum .080″

5052 Aluminum .100″

5052 Aluminum .125″

5052 Aluminum .190″

5052 Aluminum .250″

5052 Aluminum .375″

5052 Aluminum .500″

We guarantee awesome quality parts. If you’re not 100% happy, we’ll give you a refund or remake on the spot – no questions, no hassle.

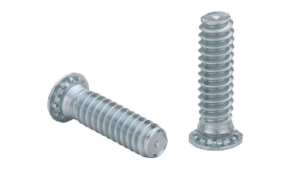

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild

| SKU | FH-M8-12 |

| Thread Size | M8 x 1.25 |

| Hole size in sheet (+0.003/-.0.000) | .315″ |

| Minimum sheet thickness | 0.094″ |

| Maximum sheet thickness | .347″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.378″ |

| Minimum distance between two of the same hardware | .567″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .472″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.100″-0.250″ |

| Steel material ranges (CRS, HRPO, HR) | 0.104″-0.250″ |

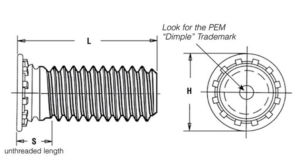

We proudly use hardware by PEM

Aluminum: 5052, 6061, 7075 Steel: Mild, G30

| SKU | SO-440-8 |

| Thread Size | 4-40 x .250″ |

| Hole size in sheet (+0.003/-.0.000) | .168″ |

| Minimum sheet thickness | 0.040″ |

| Maximum sheet thickness | .125″ |

| Fastener material | Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. | .345″ |

| Recommended panel material | Steel/Aluminum |

| Coating type | Zinc |

| Length | .250″ |

| Aluminum material ranges (5052, 6061, 7075) | 0.040″-0.125″ |

| Steel material ranges (CRS, HRPO, HR) | 0.048″-0.119″ |

We proudly use hardware by PEM

Stainless Steel: 304, 316

| SKU | SO4-440-8 |

| Thread Size | 440 |

| Hole size in sheet (+0.003/-.0.000) | .166″ |

| Minimum sheet thickness | 0.04″ |

| Maximum sheet thickness | .125″ |

| Fastener material | 400 Stainless Steel |

| Minimum distance hole C/L to edge | 0.230″ |

| When determining the distance between two or more fasteners, you can calculate the distance by the formula, C/L to edge + 1/2 the diameter of the second mounting hole. Example shown with x2 of the same hardware. | .313″ |

| Recommended panel material | Stainless Steel |

| Coating type | Passivated |

| Length | .250″ |

| 304 Stainless Steel material ranges | 0.048″-0.125″ |

| 316 Stainless Steel material ranges | 0.060″-0.125″ |